Use the D.I.Wire Pro only as instructed in this

manual. Make sure you read all the instructions

and safety precautions before using the machine.

Before Use:

The D.I.Wire PRO is to be used by qualified

personnel only.

This manual contains valuable info about the

operation, care and service of your machine.

We recommend you keep it handy.

Note: The instructions in this manual are not meant

to cover every possible condition and situation

that may occur. Common sense and caution must be

practiced when setting-up, operating

and maintaining any equipment.

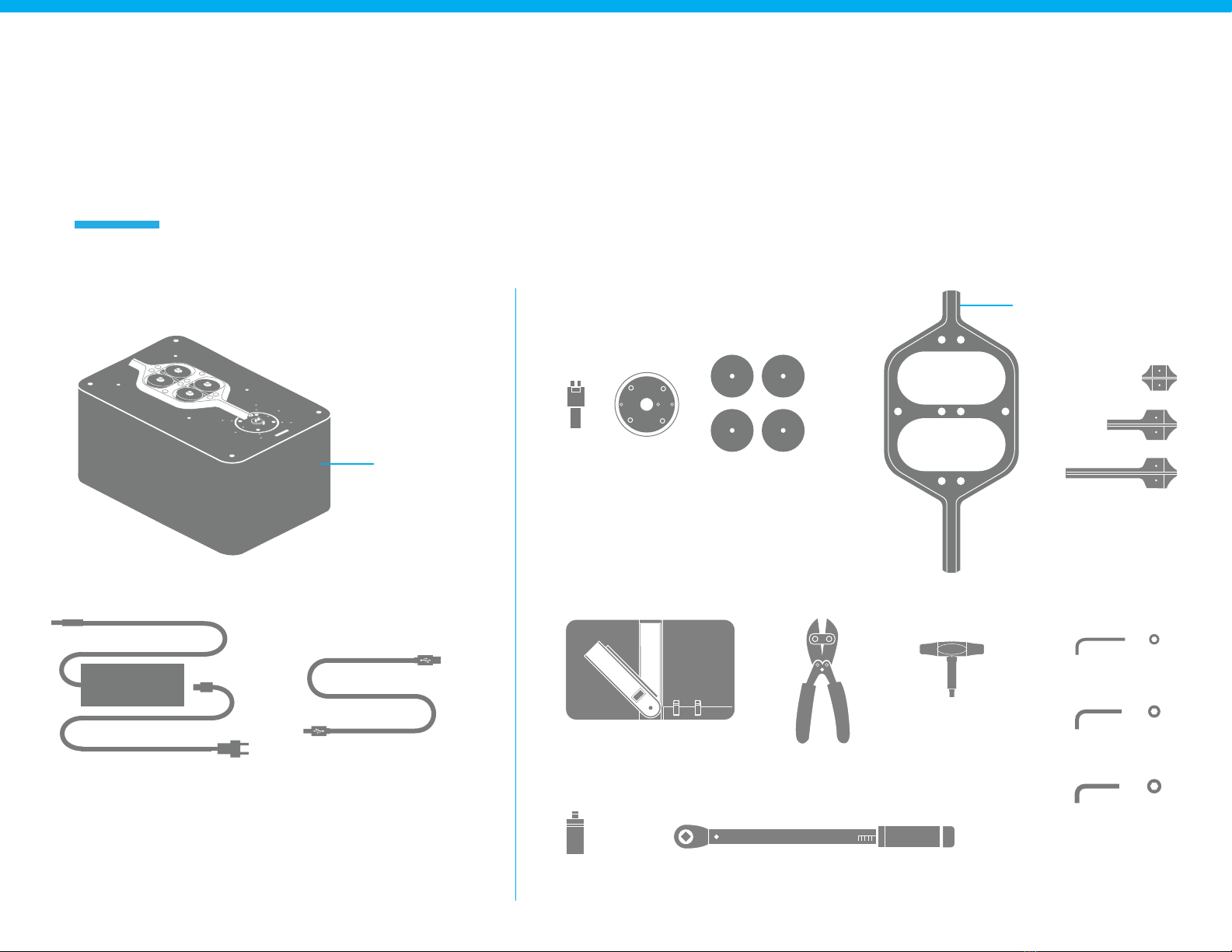

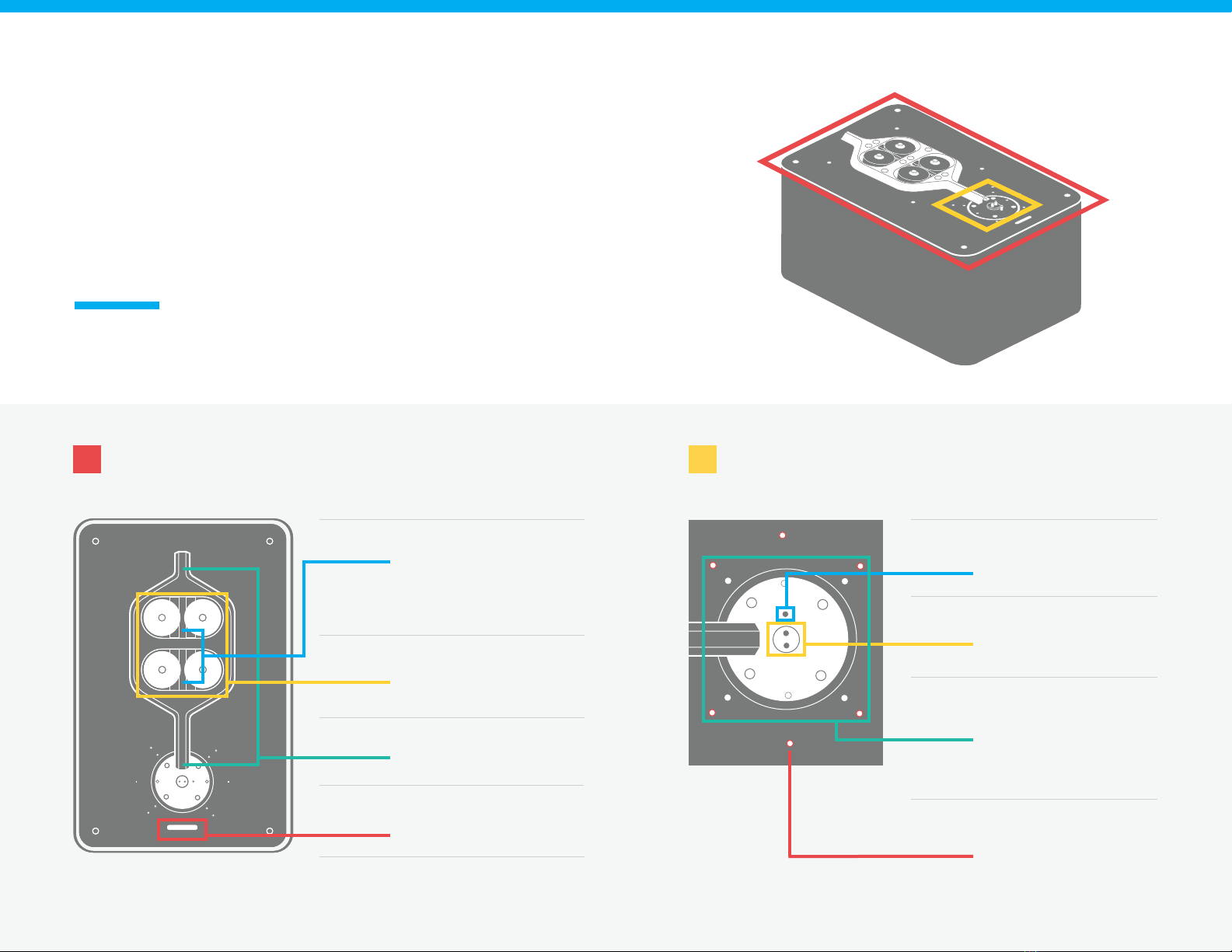

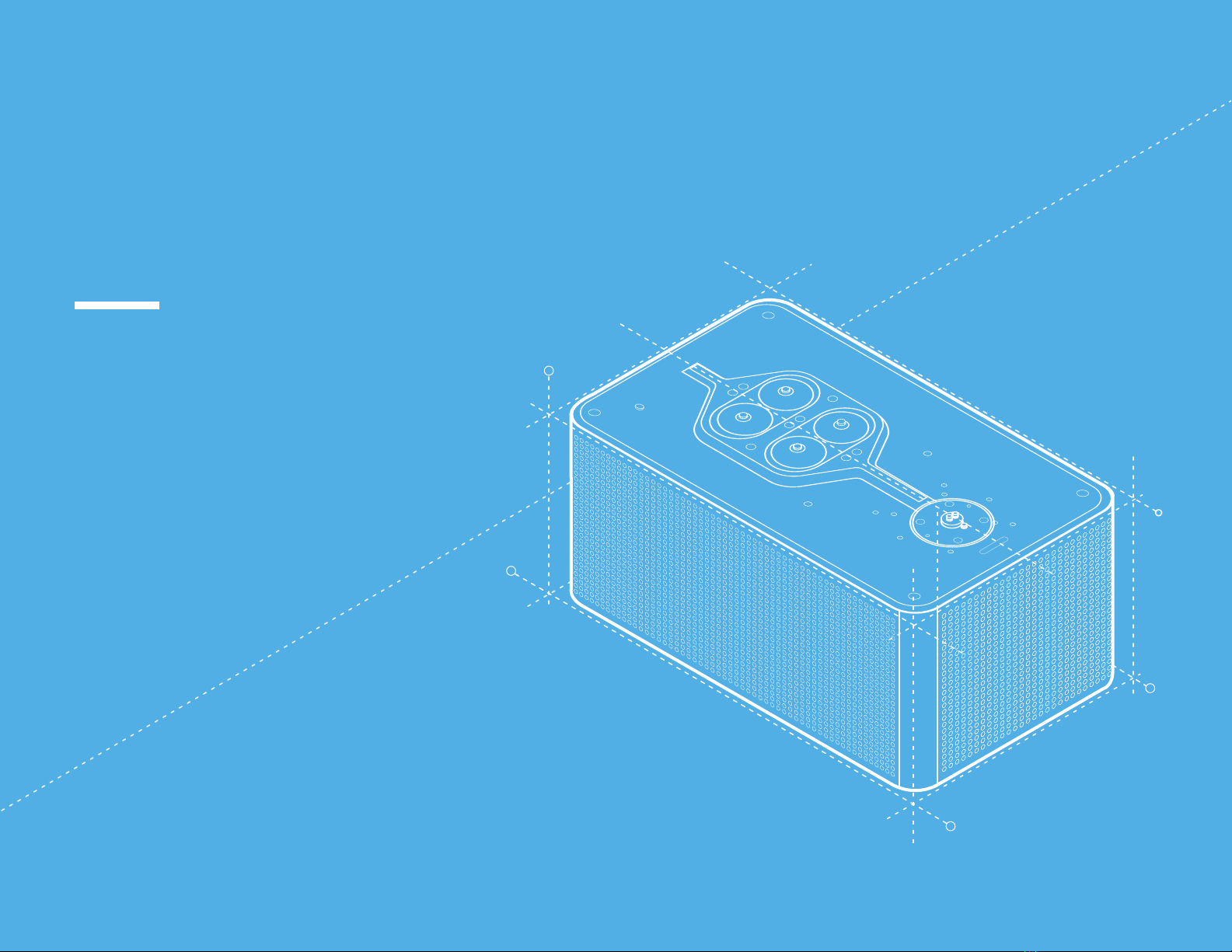

The D.I.Wire Pro

01 INTRODUCTION

6