- 8 -

• Always read and follow the chemical label instructions exactly. Understand safe practices for chemical handling,

mixing,loading,cleaning,andrstaid.

• Always wear proper Personal Protective Equipment when handling chemicals, including gloves, eye protection,

respirator and safety shoes.

• Always pay attention to wind conditions when using the Cleanload. DO NOT use Cleanload in wind in excess of

10MPH due to possibility of tipping.

• Always check to make sure that there are no loose objects surrounding the Cleanload that could cause damage to

the hopper tank or hoses.

• WhenoperatingtheCleanloadatnight,ensureproperlighting(200to300Lux)ispresent.

• IMMEDIATELY SHUT DOWN the system if leaks, errant spray, operation error, or malfunction occur.

Start-up, Operation, Shutdown

Before Operation

• Inspect the assembly for signs of leaks.

• EnsureallhosesorttingsareproperlyattachedtotheCleanload.

• Ensurehoppervalve(redhandle)andCyclorinsevalve(bluehandle)areintheclosedpositionandthatthebypass

valve(yellowhandle)isintheopenposition.

• Ensureproperpump/systemsizingforpropereductorfunctionpriortousingchemicals.Trialwithwateris

recommended to ensure safe operation. Proper function is indicated by water being drawn into the line, and not

backing up inside the hopper.

• Ifwaterbacksupinhopperwhenthepumpison,ensurethehoppervalve(redhandle)isopentoallowowfromthe

enclosure.Ifthebackuppersists,immediatelyclosetheCycloRinse(bluehandle)andthehoppervalve(redhandle)

and shut off the pump. Review outlet plumbing to minimize restrictions or blockages.

Start-up, Operation, Shut Down

1. Turn on the pump to generate clean water flow.

2. Openthetankhopper(redhandle)andtheCycloRinsevalve(bluehandle),closethebypassvalve(yellowhandle)

3. Inspect assembly for leaks.

4. Openthechemicalcontainer,pourandmeasurethechemical.Pourthemeasuredchemicalintohopper.

5. Triple rinse the measurement container using bottle rinse inside hopper

6. Ifmorethanonecontainerisneededrepeatsteps4&5.

7. Rinsechemicalcontainer(s)toensureanychemicalsontheexteriorareremoved.

8. Ifcontainer(s)areempty,triplerinsethecontainer(s)usingbottlerinseinsidehopper.

9. ClosetheCyclorinsevalve(bluehandle)andwaitfor15seconds.Closethehoppervalve(redhandle).

10. If more chemicals need to be added to the tank repeat steps 1-11.

11. Openthebypassvalve(yellowhandle)andcontinuetotransferwaterasneededorshutoffpump.

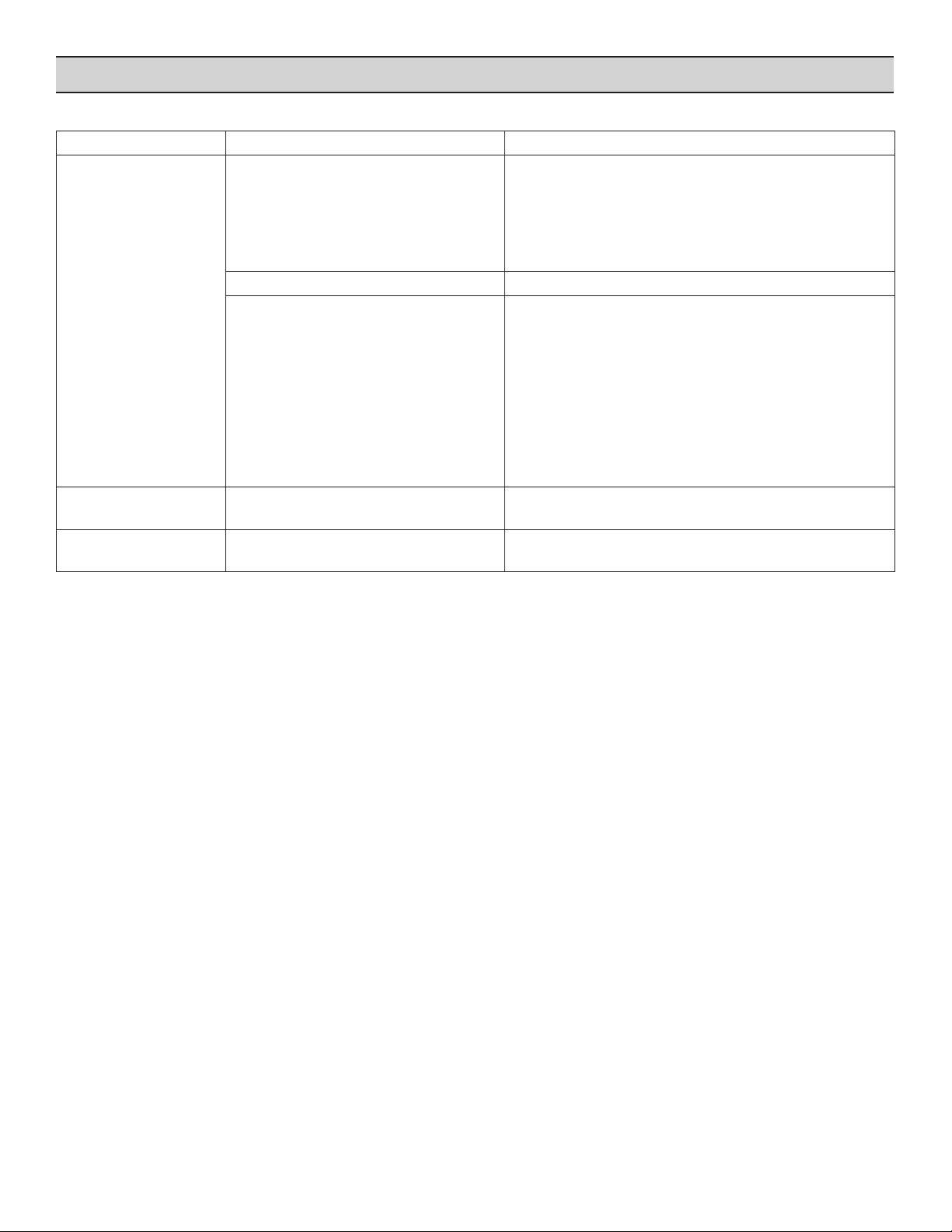

Maintenance and Servicing

Information

ATTENTION: DivertorstopallowtoandfromtheCleanloadsystembeforeperforminganyserviceormaintenance

procedures.

ATTENTION: Always wear proper Personal Protective Equipment when handling chemicals including gloves, eye

protection, respirator and safety shoes.

ATTENTION: Always dispose of chemicals and contaminated water in accordance with national and local laws and

statutes.