4

motor in 220 degree oven

for four hours. Recheck

after motor cools. If motor

is new or thoroughly dry,

needle of ohmmeter will not

move on the ground check:

This indicates a reading of

50 megohms or higher. One

megohm is one million ohms.

When making the ground

check, if the needle goes

to zero the motor in all

probability has a wire

touching the stator shell at

some point and the stator

will have to be replaced.

5. Winding resistance test. If

motor shows a satisfactory

ground check then the

winding resistance must

be checked. Use ohmmeter

with scale pointer set on

R x 1 scale. On this scale,

meter reads directly on

ohms. Always check the

meter with leads together

as described above, under

ground check, before making

a reading on the winding.

Connect one meter lead to

the terminal with the brown

wire connected underneath

the terminal board. Connect

the other lead to the terminal

housing with the blue wire.

Meter should read 1.2 to 1.4

ohms; this is the resistance

of the main winding for a

115 volt stator. This reading

for a 230 volt stator should

be 4.8 to 5.9 ohms. Now

connect one meter lead to

the brown wire terminal

and the other meter lead

to the red wire beneath the

terminal board. The meter

should read 3.8 to 5.4 ohms

for a 110 volt stator. For a

230 volt stator this reading

should be 16 to 21 ohms.

This is the resistance of the

start winding. Now connect

one meter lead to the red

wire and one to the blue

wire. The meter reading

should be the sum of the

other two readings or 5.0

to 6.8 ohms for a 115 volt

stator or 20.8 to 26.9 ohms

for a 230 volt stator. If the

readings obtained do not

agree with those given, the

stator is defective and must

be replaced.

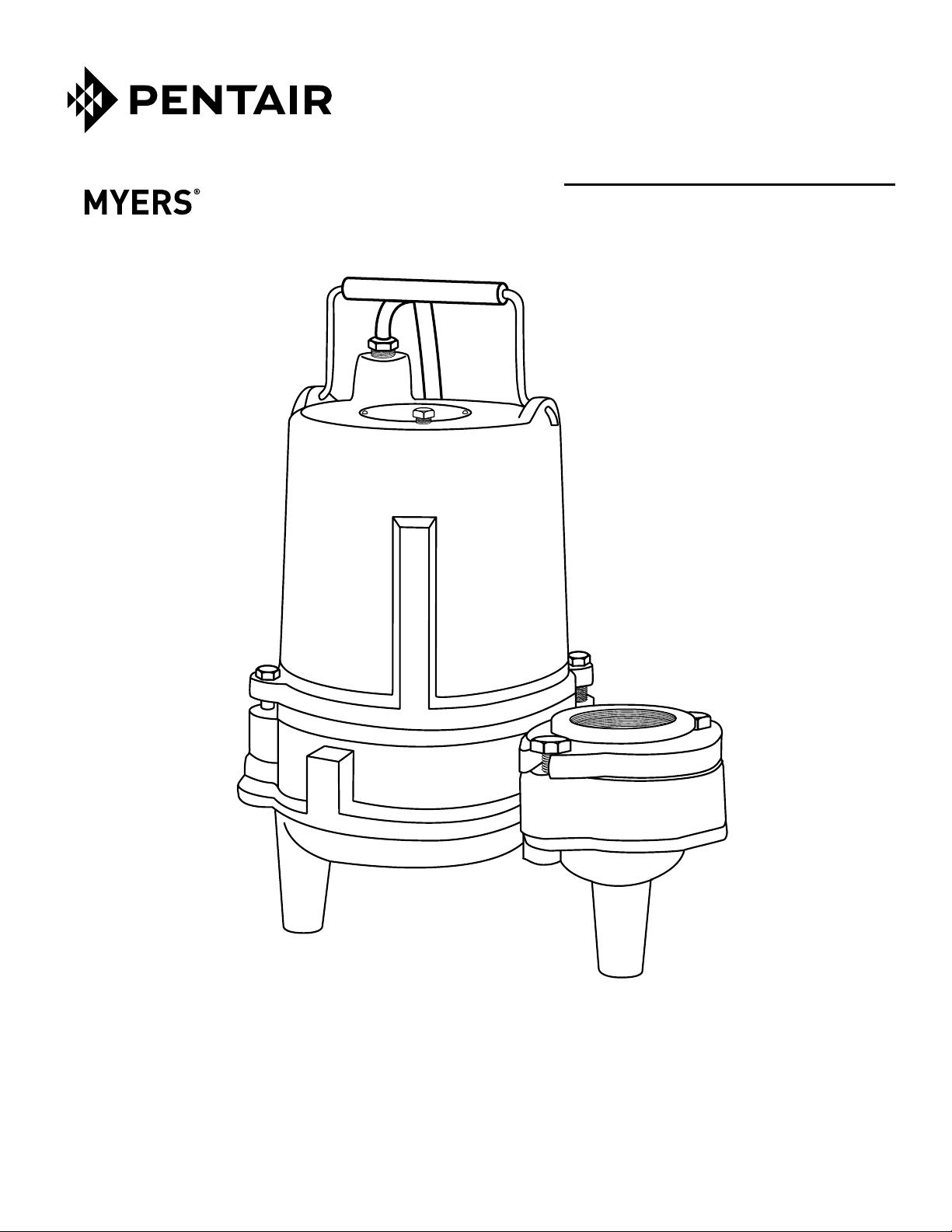

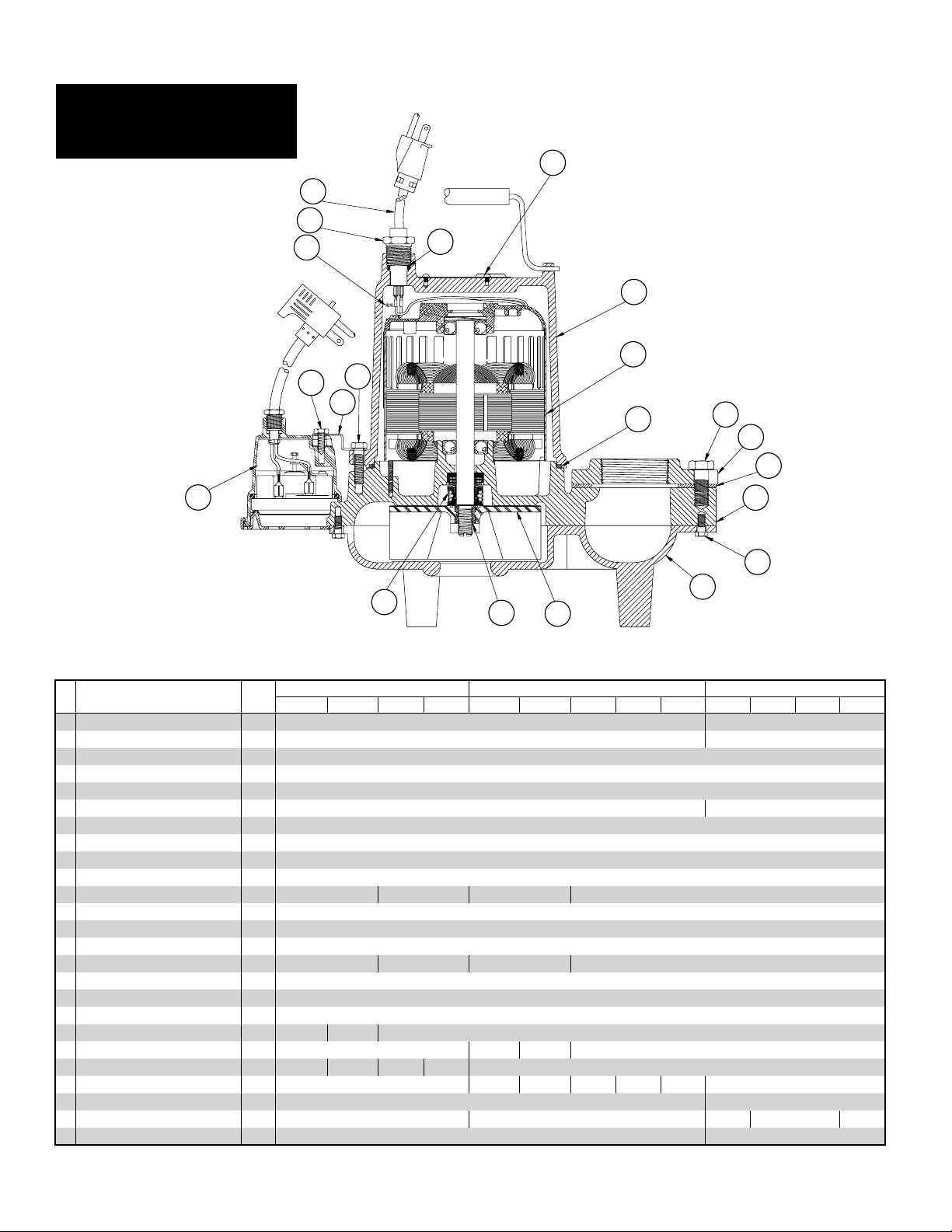

6. Replacing seal. If water

is found in motor, seal

must be replaced. Remove

bottom casting (5). Place

screwdriver in shaft slot and

tap impeller (6) lightly with

hammer to unscrew. Use

cloth on impeller to prevent

cutting hand. Tap on end

of shaft with a plastic or

rubber hammer. This will

push seal (8,9) from shaft.

Clean case thoroughly;

all sand and dirt must be

removed. Remove stationary

ceramic seat of seal from

housing. Push new ceramic

seat into housing. Use

Parker O-ring lube on

rubber ring. Replace rotor in

housing. Use care in putting

shaft through ceramic seat

to be sure it is not chipped.

Inspect seal after shaft is

in place. If seal has been

chipped it must be replaced.

Do not replace rotating part

of seal until the balance of

the pump is assembled.

7. Bearings. When the pump

rotor has been removed,

check bearings before

replacing. If bearings are

rusted or rough when turned,

they must be replaced. Pull

bearings with a bearing

puller. If puller cannot be

replaced over lower bearing,

remove the outer race by

cracking in a vise. After outer

race is cracked, it can be

removed and the balls can

be removed. This will allow

inner race to be pulled.

When replacing bearings

push only on inner race.

If a press is not available,

bearings can be tapped on,

using a sleeve that bears

only on the inner race.

Never pound on the outer

race or bearing will be

ruined.

8. Reassembly of stator and

housing. Replace stator (20)

with terminal block turned

toward switch pocket as

shown by drawing. Replace

plate and bolts (2). Be sure

ears on plate are in place

inside of shell of stator.

Replace cord (21) with push

on terminals in place on

terminal block. Bend tabs of

push on connectors down so

that they cannot touch plate

or housing. Place wire in

straight up position so that

housing (24) can be replaced

over wire. Be sure bearing

load springs are in place in

housing before replacing

housing. Hold springs in

place in housing with O-ring

lube, or other heavy grease.

Be sure rubber ring (3) is

in place on case when

lowering housing into

place. Tap down on top

of housing with plastic or

rubber hammer to seat over

bearing. Replace screws

(10) and tighten evenly from

one side to the other until

housing is firmly in place.

At this point turn shaft to be

sure rotor is free. If rotor

binds, it indicates screws

are not tightened evenly.