2

Index

1. IPFC Introduction............................................................................................................................................................... 3

2. Safety Instructions............................................................................................................................................................. 3

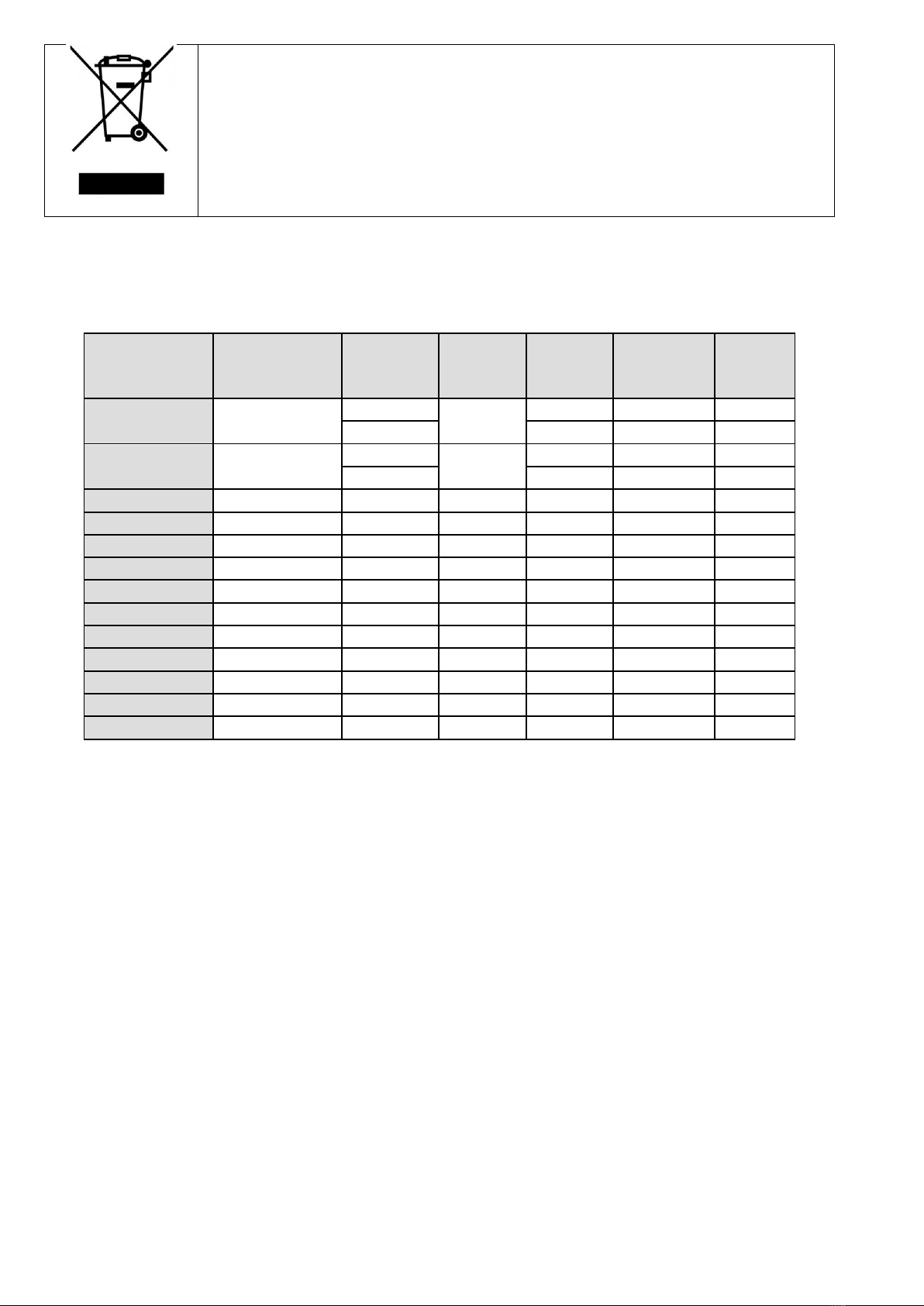

3. Technical Characteristics ................................................................................................................................................... 4

3.1 Weight and dimensions .......................................................................................................................................................... 5

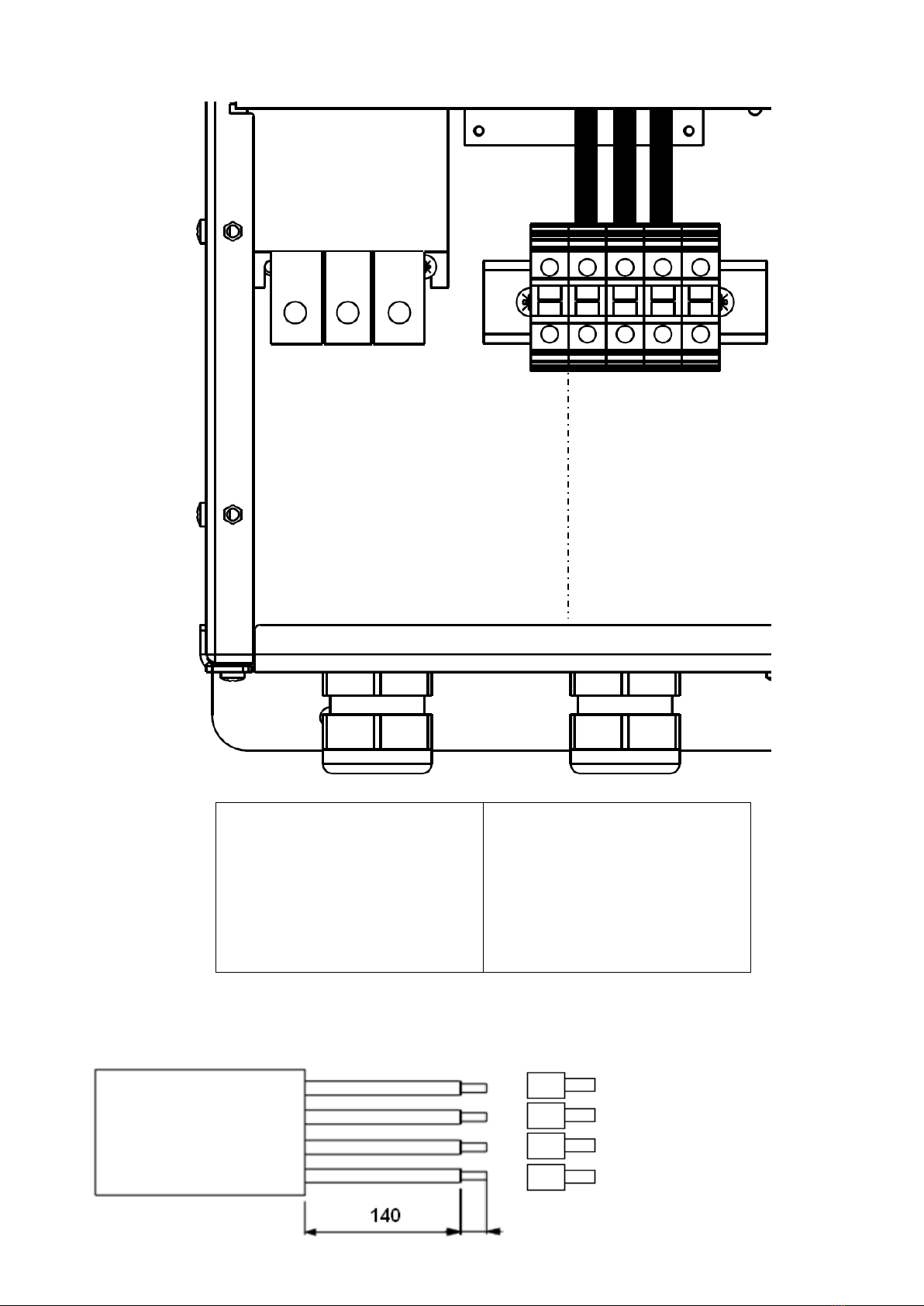

4. Electric wiring.................................................................................................................................................................... 6

4.1 Protections............................................................................................................................................................................. 11

4.2 Electromagnetic compliance.................................................................................................................................................. 11

4.3 Installation with long motor cables ....................................................................................................................................... 11

5. IPFC installation................................................................................................................................................................12

5.1 IPFC Installation for constant pressure control...................................................................................................................... 15

5.1.1 Pressure tank .............................................................................................................................................................. 15

5.1.2 Pressure sensor........................................................................................................................................................... 15

5.2 IPFC installation for differential constant pressure applications ........................................................................................... 16

5.2.1 Sensors wiring ............................................................................................................................................................. 16

5.2.2 Programming............................................................................................................................................................... 16

6. IPFC Use and Programming...............................................................................................................................................17

6.1 IPFC display ........................................................................................................................................................................... 17

6.2 Initial configuration............................................................................................................................................................... 17

6.2.1 FOC motor control ...................................................................................................................................................... 19

6.3 Initial view ............................................................................................................................................................................. 21

6.4 Menu view............................................................................................................................................................................. 22

6.5 Control parameters ............................................................................................................................................................... 22

6.6 Motor parameters.................................................................................................................................................................. 26

6.7 IN/OUT parameters................................................................................................................................................................ 29

6.8 Connectivity parameters........................................................................................................................................................ 30

7. Protections and alarms.....................................................................................................................................................30

8. Auxiliary pumps during constant pressure control ...........................................................................................................32

8.1 DOL pumps............................................................................................................................................................................ 33

8.2 COMBO function .................................................................................................................................................................... 34

9. Trouble-shooting chart .....................................................................................................................................................37

10. Technical Assistance .......................................................................................................................................................38