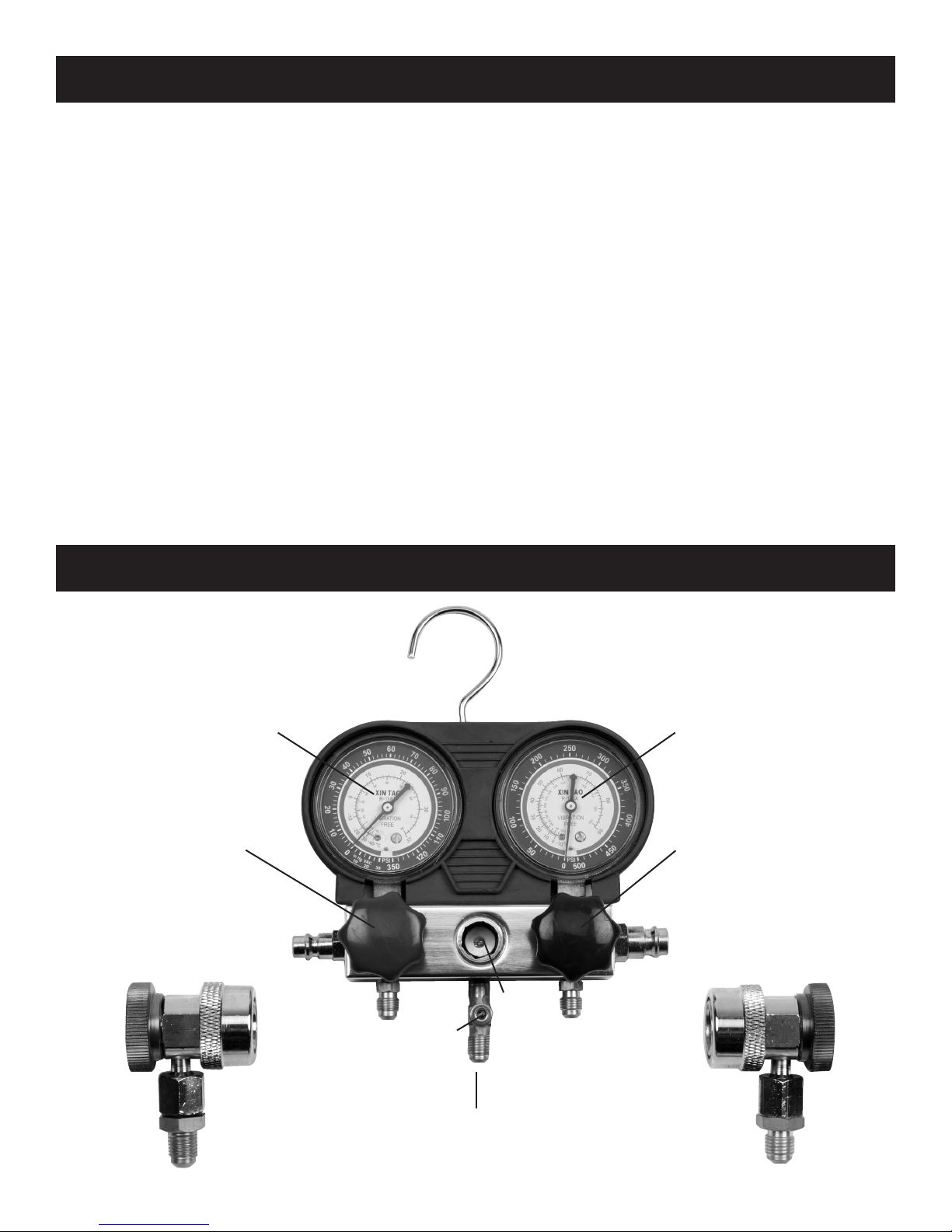

PRODUCT SPECIFICATIONS

Blue (Low) Gauge 0-120psi

Blue Hose ¼ in. FFL x 50 in.

Red (High) Gauge 0-500psi

Red Hose ¼ in. FFL x 50 in.

Yellow Hose ½ in. ACME x 50 in.

Gauge Accuracy +/-2%

1. Keep work area clean and well lit.

2. Keep children away. Children must never be allowed

in the work area. Do not let them handle the A/C Mani-

fold Gauge Set.

3. There are certain applications for which this A/C

Manifold Gauge Set was designed. It will do the job bet-

ter and more safely at the rate for which it was intended.

Do not modify this A/C Manifold Gauge Set and do not

use this A/C Manifold Gauge Set for a purpose for which

it was not intended.

4. Dress properly. Do not wear loose clothing or jewelry

as they can be caught in moving engine parts. Protec-

tive clothes and nonskid footwear are recommended

when working. Wear restrictive hair covering to contain

long hair.

5.

Wear ANSI-approved impact safety goggles and

heavy-duty work gloves at all times during setup and use.

6. Do not overreach. Keep proper footing and balance at

all times.

7. Maintain gauge with care. Keep the A/C Manifold

Gauge Set clean for better and safer performance.

Inspect hoses periodically, and if damaged, have them

repaired by a qualified technician.

8. Stay alert. Watch what you are doing, use common

sense. Do not operate gauge when you are tired.

9. Check for damaged parts. Before using any gauge,

any part that appears damaged should be carefully

checked to determine that it will operate properly and

perform its intended function. Check for alignment and

binding of moving parts; any broken parts or mounting

fixtures; and any other condition that may affect proper

operation. Any part that is damaged should be properly

repaired or replaced by a qualified technician.

10. Replacement parts and accessories. When servic-

ing, use only identical replacement parts. Use of any

other parts will void the warranty. Only use accessories

intended for use with this gauge.

11. Do not operate gauge if under the inuence of alco-

hol or drugs. Read warning labels if taking prescription

medicine to determine if your judgment or reexes are

impaired while taking drugs. If there is any doubt, do not

operate the gauge.

12.

Maintenance. For your safety, service and maintenance

should be performed regularly by a qualified technician.

13.

Industrial applications must follow OSHA requirements.

14. People with pacemakers should consult their

physician(s) before using this product. Electromagnetic

fields in close proximity to a heart pacemaker could

cause interference to or failure of the pacemaker. In

addition, people with pacemakers should observe the

following: Caution is necessary when near the coil, spark

plug cables, or distributor of a running engine.

16. The warnings, cautions, and instructions discussed

in this instruction manual cannot cover all possible condi-

tions and situations that may occur. It must be under-

stood by the operator that common sense and caution

are factors, which cannot be built into this product, but

must be supplied by the operator.

17. ONLY USE REFRIGERANT R-134a WITH THIS A/C

MANIFOLD GAUGE SET.

18. Do not start an engine in an enclosed area (like a

garage). A running gasoline engine generates carbon

monoxide; carbon monoxide is a colorless, odorless gas

that can cause serious injury and death, if inhaled.

19. Keep hands away from the moving parts and hot

parts of vehicle’s engine.

20. Read and understand all instructions and safety

precautions as outlined in the vehicle manufacturer’s

manual for air condition servicing. Only qualified me-

chanics that are trained in servicing air conditioning

systems should use this product.

21. When warming up an engine in preparation for

checking of the A/C system, make sure the vehicle’s

transmission is placed in “Park” and the emergency

brake is applied.

22. Refrigerant can cause severe frostbite if it comes in

contact with skin.Follow the safety warnings and instruc-

tions provided by the refrigerant manufacturer.

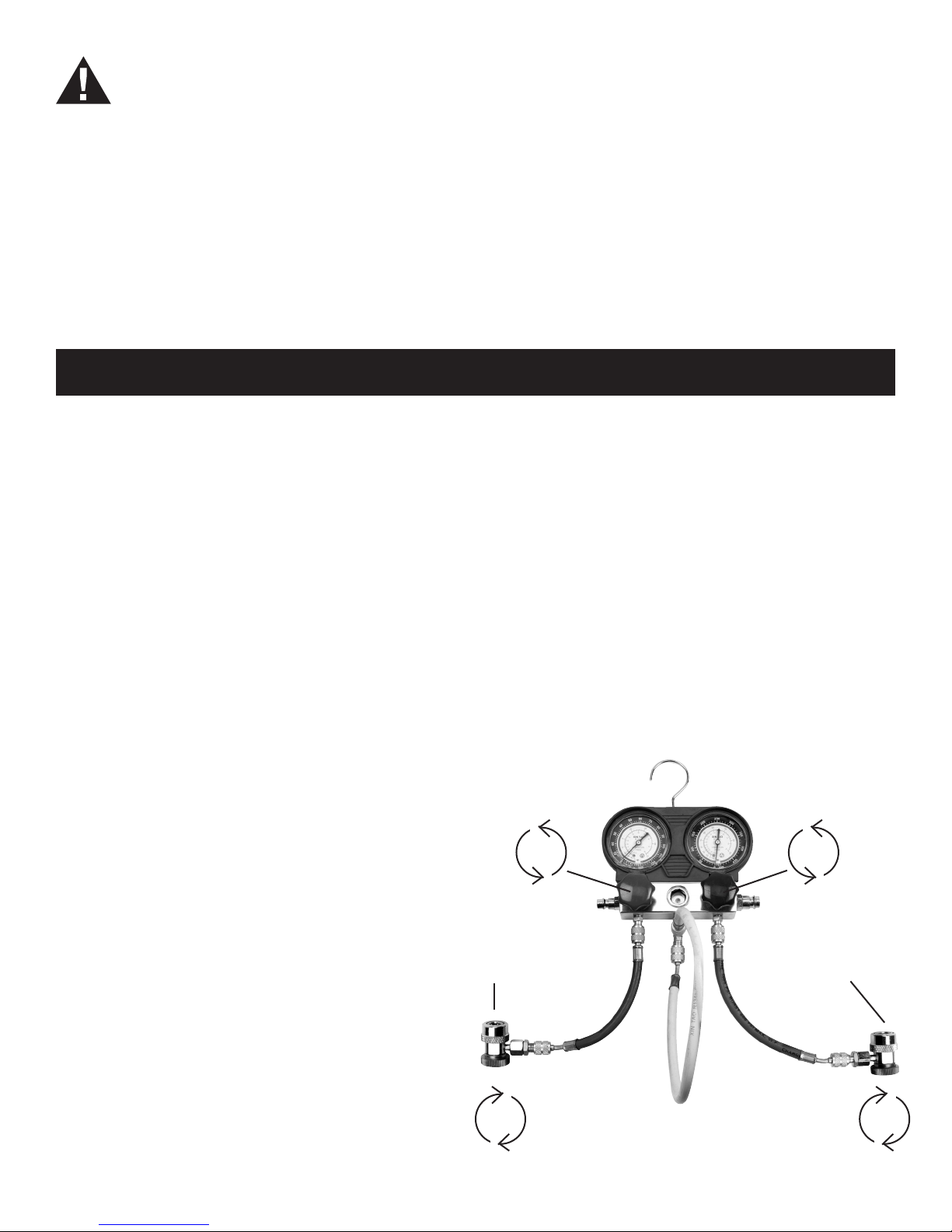

23. Do not disconnect any pressurized hose. Pressur-

ized refrigerant can cause severe injury.

24. Use caution when opening an air conditioning sys-

tem line or can of refrigerant. When checking, always

place a towel around the service valves of the air condi-

tioning unit and Red and Blue Couplers (22 and 23).

25.

Keep refrigerant away from excessive heat as pressure

in the container could increase enough to rupture the can.

26.

Do not discharge refrigerant into the atmosphere.

Capture refrigerant into an approved recovery container

(not included), and then dispose of properly. Contact your

local Hazardous Waste Authority for disposal guidelines.

27. Only use refrigerant in a manner consistent with the

air conditioning system’s repair manual.

SAVE THESE

INSTRUCTIONS