2performaxopeners.com Customer Service: 1-877-436-4402

BEFORE YOU BEGIN SAFETY INSTRUCTIONS

To reduce the risk of severe injury or death:

1. READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2. Install only on a properly balanced garage door. An improperly balanced door has the

potential to inflict severe injury. Have a qualified garage door service technician make

repairs to cables, spring assemblies, and other hardware before installing the opener.

3. Remove all ropes and remove or make inoperative all locks connected to the garage

door before installing opener.

4. Where possible, install the opener no more than 12" above the height of the closed door.

For products having an emergency release, mount the emergency release within reach, but

at least 6 feet above the floor and avoiding contact with vehicles to avoid accidental release.

5. Do not connect the opener to source of power until instructed to do so.

6. Install the door control button: (a) within sight of door, (b) at a minimum height of 5 feet

so small children are not able to reach it, and (c) away from all moving parts of the door.

7. Install the Entrapment Warning Label (shown in the

Before You Begin

section) next to

the wall-mount control button in a prominent location.

8. Aer installing the opener, the door must reverse when it contacts a 1-1/2 inch (3.8 cm)

high object (or a 2x4 board) laid flat on the floor.

9. NEVER try to remove, loosen, move, or adjust garage door, cables, pulleys, brackets,

and door springs. All are under EXTREME tension.

10. To reduce the risk of injuries to persons – use this operator only with residential sectional

garage doors. Only enable the unattended operation feature when installed with a

sectional door.

11. The Smart Door Controller should be used only on sectional doors and with garage door

openers made aer 1993 with a photo eye safety system.

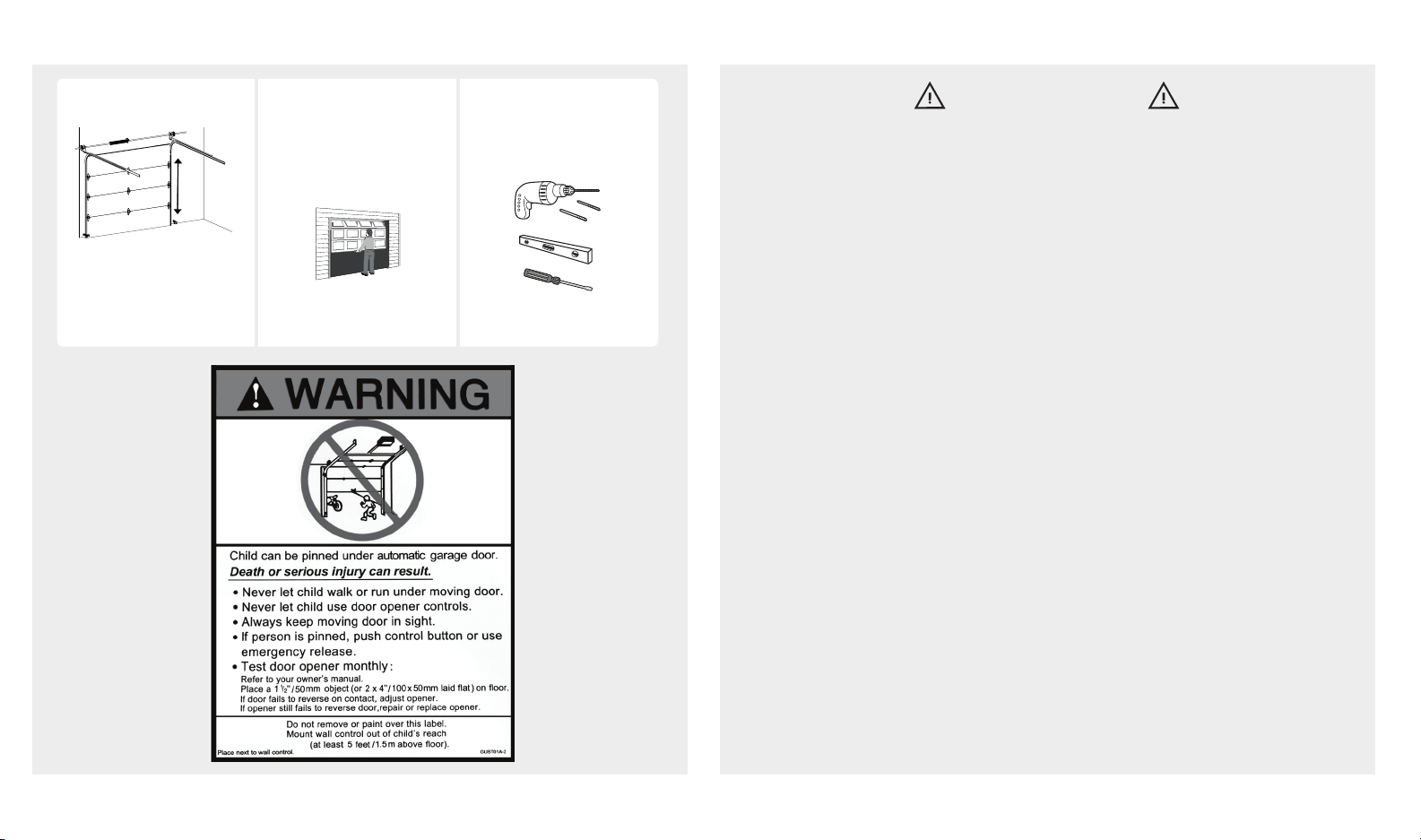

WARNING

Measure door height. Check mounting

locations. Are additional

reinforcement

materials needed?

If over 7.5 feet (2.28 m), rail

extension kit will be needed.

(8 . or 10 . extension kits

available if needed.) See page 3

Entrapment

Warning Label

See page 3

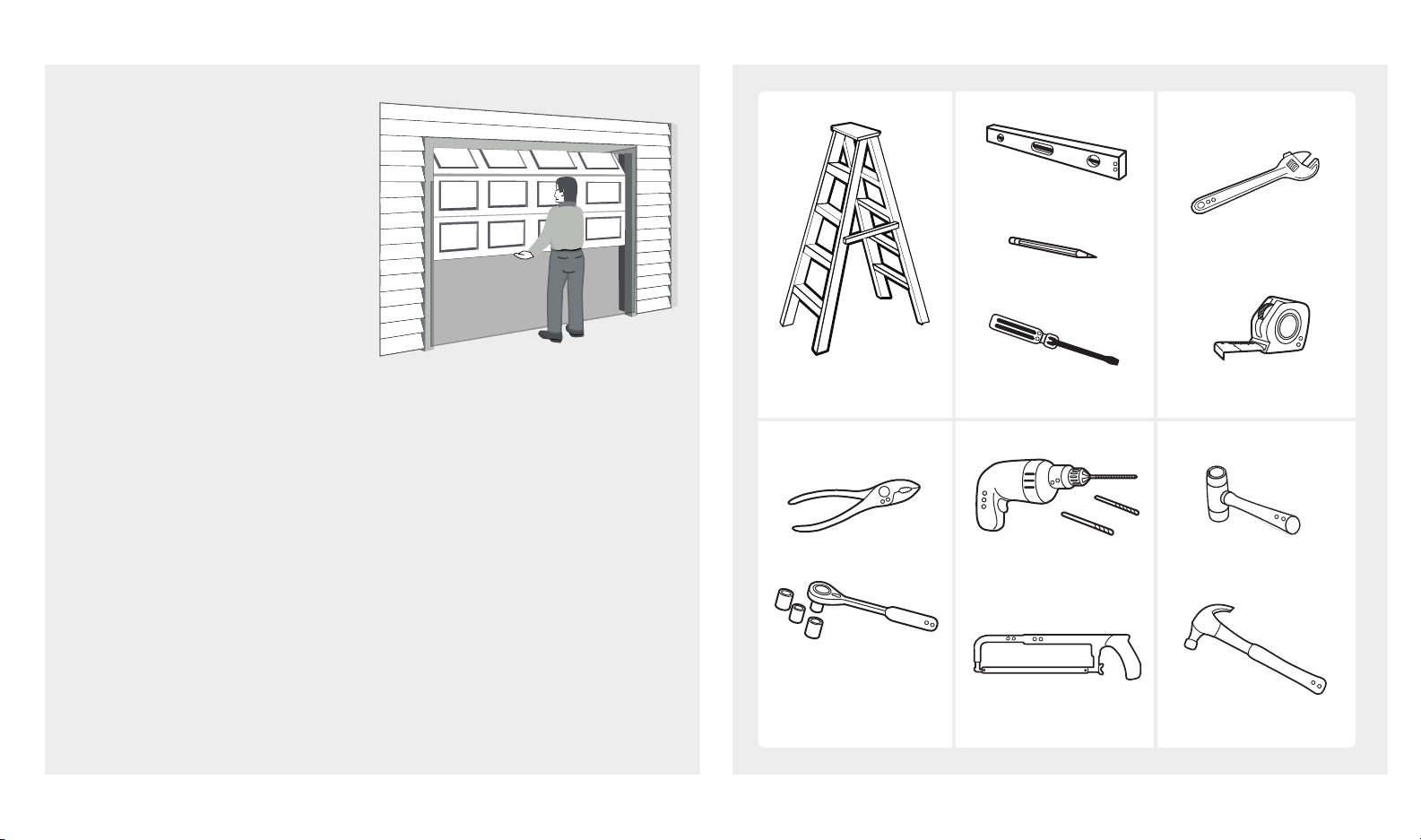

Check your toolbox.

Do you have all the

tools needed?

7.5 feet

(2.28 m)