PerkinElmer MEIZHENG BMZ6000 User manual

BMZ6000 Strip Reader

Operation Manual

1

Contents

Part 1: Introduction ......................................................................................... 2

Part 2: Technical specications.................................................................... 3

Part 3: Installation ........................................................................................... 4

Part 4: Operating Procedures ....................................................................... 5

Part 5: Testing Operation ............................................................................. 8

Part 6: Maintenance ...................................................................................... 13

Part 7: Contact Us .......................................................................................... 15

2

Part 1: Introduction

1.1 Applications

1.1.1 Intended Use

The BMZ6000 is a laboratory instrument intended for the food safety industry testing

use. It is a specic instrument intended to be used by trained laboratory professionals who

are capable of the appropriate features and options for the testing application. Contact

your local instrument provider to arrange for training.

1.1.2 Summary of the instrument

This instrument reads the results both quantitatively and qualitatively with online test

and single machine test mode options.

The calculations are pre-stored in the instrument, the standard curves for different

testing items and samples can be read by scanning the IC card or the QR code in which

the information are written.

The testing results can be printed out through the printers installed in the instrument or

imported into the computer for long term storage or data tracing purpose.

1.1.3 Principles of Operation

The BMZ 6000 instrument adopts the principle of reection photometry and gets the

result by measuring the degree of the reection of signal decays. The light is reected by

the NC membrane of the test strip and the reected light is received by the photocell and

converted into electric signal. There is corresponding relation between the residues of gold

particle on the NC membrane and the electrical signal thus the result can be interpreted by

analyzing the reection spectrophotometry.

1.2 Precautions

To assure operator safety and prolong the life of your instrument, carefully follow all in-

structions outlined below.

1) Make sure the voltage of the power supply matches the voltage range of this device

which described in the instruction.

2) Use only the power cord specied for this product and certied for the country of

use.

3) This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth ground.

4) Do not put or operate in wet/damp Conditions.

3

5) Please use the supplied or the recommended accessories.

6) Do not use the instrument once the it woks abnormal or damaged.

7) Do no operate the instrument near heat source.

8) Refer to the installation instructions for details on installing the product so it has

proper ventilation.

9) Please use the instrument on a at working surface, and do not put anything on the

instrument when it is in use.

10) Keep the instrument away from strong electromagnetic eld interference source.

11) Avoid direct sunlight.

12) Face to the back of the instrument there are two USB interfaces, the left one is

used for connecting the USB device to export data (for user) and the right one is debug

interface (for the engineer to debug the instrument).

Part 2: Technical Specications

2.1 Electronic:

Power Requirements:

In put: 100 - 240V AC, 50-60Hz. All power cords must be approved for the country of

use.

Out put: 12V, 3A

PC Connection: USB Port

Speed: Reads the cassette in approximately 7 seconds

Cassette Transport: Stepper motor

USB port: USB cable provided

2.2 Physical

Enclosure: Plastic enclosure

Dimensions: 21x21.3x15cm

Weight: 2.5kg

2.3 Environmental

Operating Temperature: 15 to 35° C

Humidity: Between 10% and 85% non-condensing

Storage Temperature: 10 to 50° C

Altitude: 2000m maximum

4

Part 3: Installation

3.1 Unpack Instrument

Carefully unpack the instrument, removing it from its plastic bag. Report any damage

to your freight carrier at once. The box will also contain the Operator’s Manual, a warranty

card, a power cord, a USB cable, four blank cassettes.

NOTE: Retain the original packing material for future use in the event that the instru-

ment is shipped to another location or returned for service.

Unpacking Checklist

Quantity Description

1 Warranty card

1 Operator’s Manual

1 Power cord

1 USB cable (option)

1 Reader

4 Blank cassette

Instrument Mounting and Use

Place the instrument on a at working surface capable of safely supporting the weight

of the instrument. Excessive vibration during reading may cause poor repeatability; thus,

a sturdy working surface is required. A clearance of at least 8cm around the instrument is

required to assure optimal ventilation.

Power Switch Position

When installing the power cord the unit should be turned o. Look at the rear panel of

the instrument to check that the power switch is in the OFF position. A diagram of the rear

panel can be found in the Section Parts and Controls.

Safety Grounding

Do not alter or defeat the safety grounding methods provided. To avoid the risk of elec-

tric shock, the third prong of the AC power plug must be connected to conductive parts

internal to the equipment.

Assure Power Availability

The circuit used should be substantially free of large voltage transients (Kilovolt amp

loads) such as large pumps, large centrifuges, refrigerators and freezers, air condition-

ers, large autoclaves, ovens, and dryers. The instrument may fail to operate normally if the

power supply is interrupted. If this occurs, turn the instrument o for a moment. When the

instrument is turned back on, it will resume normal operation.

5

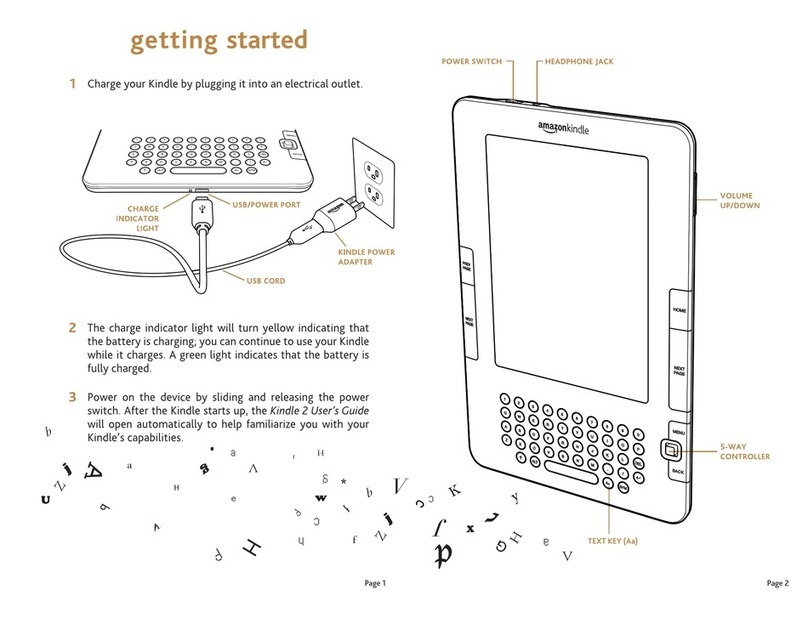

3.2 Parts and Controls

3.2.1 Parts of the Instrument

1. Touch screen; 2. Cassette transmit channel; 3. TEST button; 4. QR code scanning

window;

5. IC CARD reading area; 6. Thermal printing paper bin; 7. Sliding window; 8. Cassette; 9.

Thermal printing paper

10. Switch; 11. Power cord connection; 12. Internet access; 13. USB interface; 14. RE-

SET button; 15. Heat radiation window; 16. Speaker hole

Part 4: Operating Procedures

4.1 Power on/o

4.1.1 Power On

Press the switch upwards to turn on the instrument.

4.1.2 Power O

Press the switch downwards to shut down the instrument.

6

4.2 Strip Reading Operation

Put the test strip into the cassette and insert the cassette into the hole of the reader

(gure “a” bellow) and keep the lines (control and test lines) on the strip upwards. And fol-

low the test procedure to start testing.

4.3 Standard Curve Input

4.3.1 Input standard curve by using IC card

Put the IC card containing standard curve information in front of the reading area (3-

5cm), the instrument will read the information in the card and the standard curve can be

input into the instrument.

7

4.3.2 Input standard curve by using QR code

Put the QR code in front of the scanning window, the instrument will read the standard

curve.

4.4 Installation of the Printing Paper

Open the cover of the bin by pull the handle and put the thermal printing paper into the

bin of the instrument. Make sure to leave some length of the paper out of the bin. Push the

cover upwards slowly until the cover closed completely.

8

Part 5: Testing Operation

5.1 Home page

Switch on to access to the home page of the instrument. There are 6 menus on this

page: “Online test”, “Quantitative test”, “Qualitative test”, “Test record”, “Standard curve”

and “Setting”.

Note: For the rst time of use, please connect to the internet by WIFI to calibrate the

calendar and time.

9

5.2 Qualitative Test Operation

5.2.1 Access to the “qualitative test” page

Tap the “ ” menu on the main page and access to the qualitative test page.

Then tap the dierent menu to select the card type, product name and batch no, etc.

The information of sample origin and test operator can be typed in manually.

5.2.2 Standard curve management

Tap the “ ” menu on the right top of this page and access to the standard curve

management page. The standard curves for dierent test kits can be entered by scanning

the IC card or the QR code. If the standard curve already exists in the list, it is not neces-

sary to scanning the IC card or QR code.

Table of contents

Other PerkinElmer Ebook Reader manuals