Perma Tech PermaDOCK-MD User manual

Perma Tech, Inc.

“Your Single Source for ALL Your Loading Dock Needs”

TF: (800) 362-7325 | P: (716) 854-0707

sales@permatechinc.com | www.permatechinc.com

PermaDOCK-MD

WARNING : Do not install this product unless you have read and understand the

warnings and installation instructions contained in the manual.

IMPORTANT TO CHECK SHIPPING CONTAINERS BEFORE RELEASING CARRIER.

NOTIFY CARRIER IMMEDIATELY UPON DISCOVERING ANY CONCEALED DAMAGE.

Mechanical Dock Leveler

OWNER’S MANUAL

TABLE OF CONTENTS

Page

Safety Information 1

Installation Instructions 3

Shimming Details 4

Preliminary Operations 5

Operating Instructions 6

Mechanical Dock Leveler Diagram 7

Parts List for Mechanical Dock Levelers 8

Schematic Drawing & Parts List for Lifting Arm 9

Schematic Drawing & Parts List for Ratchet Hold Down 10

Schematic Drawing & Parts List for Lip Assist Assembly 11

Schematic Drawing & Parts List for Lip Latch Assembly 12

Trouble Shooting 13

Maintenance & Lubrication 14

Warranty 15

Manufacture Date:

Model:

Serial #:

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 3

Perma Tech Inc.

SAFETY INFORMATION

WARNING

Failure to read and understand the entire contents of this manual may result in damage

to the equipment, bodily injury and/or death. Never install, maintain or operate this

equipment under the influence of drugs or alcohol.

INSTALLATION

• Personnel installing this equipment must be fully qualified and experienced in safe

working procedures.

• All lifting and slinging devices must be in good working order and used in the correct

manner.

• Concrete must be in good repair with no cracks in pit or around the dock leveler.

• Never go beneath the dock leveler unless the dock is barricaded in front of the dock

leveler on the loading dock floor and driveway.

• Never go beneath the dock leveler unless the maintenance strut is in position.

• Do not alter the equipment.

MAINTENANCE

1. When replacing parts use only genuine PermaDOCK Levelers parts.

2. Never go beneath the dock leveler unless the dock is barricaded in front of the dock

leveler on the loading dock floor and driveway.

3. Never go beneath the dock leveler unless the maintenance strut is in position.

4. Do not alter the equipment.

-1-

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 4

Perma Tech Inc.

SAFETY INFORMATION

OPERATION

NOTE: ALWAYS RESTRAIN THE TRUCK/TRAILER BEING LOADED/UNLOADED, I.E. BY USE OF WHEEL

CHOCKS OR A TRUCK RESTRAINT DEVICE.

1. Keep clear of the equipment’s operating path when positioning or storing the dock

leveler.

2. Never lower the dock leveler with a lift truck.

3. Do not wear loose clothing or jewelry while operating this equipment.

4. Keep hands, limbs and loose hair clear of equipment during positioning or storing of

the dock leveler.

5. Never go beneath the dock leveler unless the maintenance strut is in position.

6. Never continue to use the equipment if you believe it is unsafe because of bent

structural members, broken welds, oil leaks, etc. Have the unit inspected by your

nearest Perma Tech Dock Leveler representative.

-2-

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 5

Perma Tech Inc.

INSTALLATION INSTRUCTIONS

Prior to installation, check pit for correct depth and square-ness of pit across corners.

If pit is not correct in size and square-ness, make corrections before installation dock

board.

IMPORTANT

Do not break bands on dock board until called for in Step 4, otherwise damage may

occur which would not be covered by the warranty.

1. Place board in pit by means of crane or forklift, level back end of board with rear pit

angle, weld angles as shown on Drawing.

2. Shim front end of board so as top deck of board is level with the rear angle.

3. Weld front base and shims to front curb angle.

4. With the board welded in the pit, remove bands; elevate deck by pulling release

chain at rear of dock.

5. Block the board securely in the up position before working underneath the dock

board.

6. Shim under back frame of the board and under the centre angle as shown on

drawing. Weld shims to the angles.

7. Read operating instructions. Operate the board several times, pausing between

operation to expel the air in system.

NOTE: WHILE THE DOCK BOARD IS FACTORY AD USTED, THEY MAY REQUIRE SLIGHT AD USTMENT ON

SITE DUE TO THE MOVEMENT IN SHIPPING AND DURING THE INSTALLATION. THIS IS NOT WARRANTY.

We reserve the right to change specifications and/or design without notice or

obligation.

Please state model number of dock board when ordering parts.

-3-

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 6

Perma Tech Inc.

SHIMMING DETAILS

-4-

18”

NOTE: Painted yellow guide line recommended

Dwg. #1 FRONT VIEW Dwg. #2

SIDE ELEVATION

PIT DEPTH

20”

Recommended

Dock Height

48”

1/4”

RUN OFF

SLOPE

1/2” Min.

Slope

6.21

Dwg. #3

LS LS LS LS

Leveling & Shims for Base

A

B

CAUTION:

Block securely

while working

under the Dock

DETAIL: SHIMMING, WELDING AND BLOCKING Dwg. #4

Approximately

3” weld at 4 places

19 1/2”

Weld Shims

to Base Frame

Weld Shims

to Center Beam Support

Shim & Weld

at Lip Support

MODEL

MD-66 74”

63”

MD-68 74”

87”

MD-610 74”

111”

MD-612 74”

135”

MD-76 85”

63”

MD-78 85”

87”

MD-710 85”

111”

MD-712 85”

135”

“B” DIM “A” DIM MODEL “B” DIM “A” DIM

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 7

Perma Tech Inc.

-5-

PRELIMINARY OPERATIONS

CAUTION

Never operate the dock leveler when someone is in front of the lip.

STEPS FOR FIRST TIME USAGE:

1. Pull and hold the release chain until the dock strops in its top position. Do not step

on the deck. When the deck lifts to its highest position the lip will extend and lock

into position automatically.

2. Walk to the top of the deck. The ramp will lower to its lowest position (below dock

level) and hold its position.

3. Manually lift the lip 2”. The lip locking mechanism will disengage. Carefully lower the

lip to its vertical position.

4. Pull the release chain until the dock raises 6” above dock level. Stop the ramp by

letting go of the release chain. Walk the ramp down to its stored position with lip

behind the night lock.

5. Continue to raise and lower the dock leveler 10-12 times. This operation will

disperse the lubricants to the bearing surfaces and reduce friction. This procedure

should be performed when the dock is not used for an extended period of time.

NOTE: DAMAGE TO THE DOCK LEVELER AND LIP WILL OCCUR IF THE LIP IS LEFT IN THE EXTENDED

POSITION WHEN A TRUCK BACKS INTO THE DOCK.

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 8

Perma Tech Inc.

-6-

OPERATING INSTRUCTIONS

CAUTION

Never operate the dock leveler when someone is in front of the lip.

Always restrain the truck/trailer being loaded/unloaded, i.e. by use of wheel chocks or

a truck restraint device.

1. Raise the dock leveler by gently pulling the release chain at rear of the deck. (Hold

the chain up until the dock rises to its highest position.) The lip will extend and lock

automatically. (FIGURE #1)

2. To lower the dock into its work position, walk to lip end of the dock. The weight of

the operator will lower the dock onto the truck or trailer. (FIGURE #2)

3. As soon as the lip is on the truck the dock is ready to be used to load or unload truck

or trailer.

4. While in use the dock will raise and lower with the movement of the vehicle and the

trailer.

5. When the truck/trailer departs the lip will fall to vertical and the dock may be walked

down to the cross traffic stored position with lip behind the night lock.

6. If necessary, raise the dock 6” above dock using the release chain, to allow the lip to

fall behind the night lock, and then walk the dock down to the cross traffic stored

position with lip behind the night lock.

WARNING: DAMAGE TO THE DOCK LEVELER AND LIP WILL OCCUR IF THE LIP IS LEFT IN THE

EXTENDED POSITION WHEN A TRUCK BACKS INTO THE DOCK.

LIP SHOULD BE A

MINIMUM OF

4" TO 6" INSIDE THE

TRUCK/TRAILER

FIGURE #1 FIGURE #2

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 9

Perma Tech Inc.

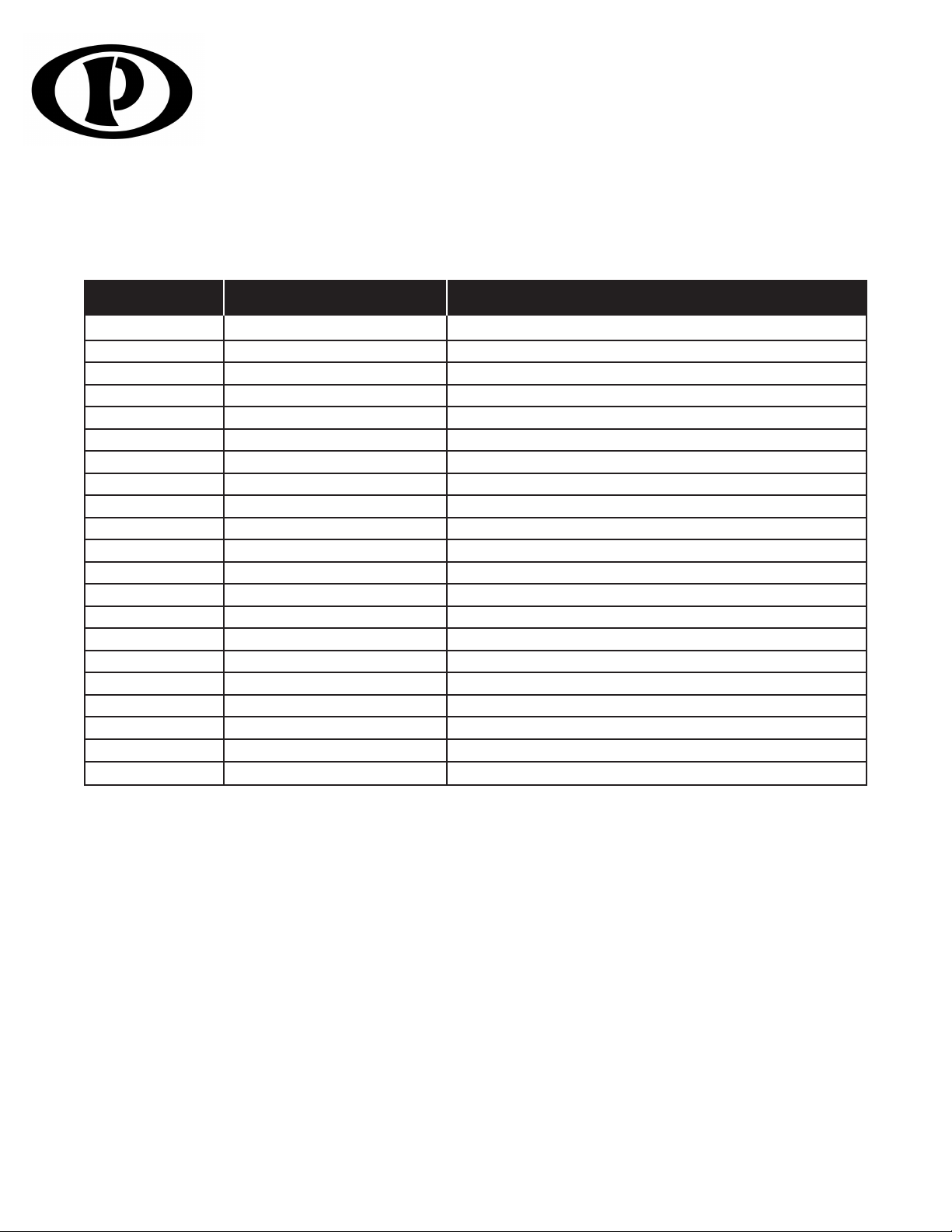

PARTS LIST FOR

MECHANICAL DOCK LEVELERS

-7-

3

10

15

13

12

11

20

21

9

14

8

7

1

2

16

5

17

19

18

4

6

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:52 AM Page 10

Perma Tech Inc.

PARTS LIST FOR

MECHANICAL DOCK LEVELERS

-8-

Item # Part # Descripti n

15P-MD 001-6, 001-7 Hinge Lip Pin

25P-MD 002-6, 002-7 Lip

35P-MD 003-6, 003-7 Top Deck Assembly

45P-MD 4Lip Latch

55P-MD 5Lip Assist Assembly

65P-MD 006-6,006-8,006-10 Telescopic Toe Guard

75P-MD 7Lifting Arm Assembly

85P-MD 8Hold Down Assembly

95P-MD 009-6, 009-810 Main Spring (Quantity Varies)

10 5P-MD 010-6,010-8,010-10 Base Frame Assembly

11 5P-MD 011-6, 011-7 Rear Hinge Pin

12 5P-MD 012 Cotter Pin

13 5P-MD 013 Back Hold Down

14 5P-MD 014 Hold Down Bracket

15 5P-MD 015 Front Hold Down Pin

16 5P-MD 016 Cotter Pin

17 5P-MD 017 Release Ring

18 5P-MD 018 Cam

19 5P-MD 019 Lip Hinge

20 5P-MD 020 Lifting Arm Pin

21 5P-MD 021-6,021-8,021-10 Spring Adjustment Bar Assembly

80136 Mechanical Leveler:80136 Mechanical Leveler 11/19/08 10:53 AM Page 11

Perma Tech Inc.

This manual suits for next models

4

Table of contents

Popular Lifting System manuals by other brands

probst

probst SDH-H-15 operating instructions

Bruno

Bruno OUTDOOR ELITE CRE-2110E Operator's manual

matev

matev FPS Mounting Assembly Installation Guide

Vestil

Vestil CYL-HLT Series instruction manual

Butts Tools

Butts Tools BXS0002 operating instructions

Safelift

Safelift MoveAround MA60 Original instructions

R. Beck Maschinenbau

R. Beck Maschinenbau HS 600 operating manual

Nova Technology International, LLC

Nova Technology International, LLC NAS Series quick start guide

Genie

Genie Z-60/34 Operator's manual

Screen Technics

Screen Technics INTERFIT Vertical Up Lift instructions

Drive

Drive DUPONT SAMERY Hermes user manual

Custom Equipment

Custom Equipment Hy-Brid 3 Series MAINTENANCE & TROUBLESHOOTING MANUAL