Pertronic Industries Ltd FAAST Power Supply Installation Note, Iss1.1 201501

Commissioning

1. Before powering up the power supply, thoroughly check the wiring for polarity and safety.

2. Check Jumper J1 on the PSU control board:

a. J1 absent (NZ Mode): A ‘Mains Lost’ condition is reported immediately upon loss of the

mains power supply.

b. J1 fitted (AUS Mode): A ‘Mains Lost’ condition is reported only if the mains power supply has

been disconnected for at least 55 minutes.

3. It is recommended that the power supply should be initially connected to the mains without load. The

green Mains On LED should light up. The two yellow LEDs should not light up. The power supply

output voltage should be about 27.4 Volts.

4. Switch off the power. Connect the load, but not the batteries. Power up the power supply. The Mains

On LED should light up, but not the yellow LEDs. Check the power supply output voltage.

5. Connect the two 12 Volt batteries to the power supply. Take care to observe the correct polarity.

Allow the batteries to charge up in accordance with the manufacturer’s recommendation.

6. Press the Reset switch for about 2 seconds. After a few seconds the Auto Test LED should light up,

indicating that the one-hour battery test has started. The Battery Fault LED should not light up.

7. Cancel the one-hour battery test by briefly pressing the Reset switch.

8. Provided the battery has adequate charge and no fault/defect has been detected, activate the load

and check that it works OK. Measure the voltage supplied to the load.

9. Put the power supply into battery test mode by pressing the Reset switch for two seconds. Check

that the load continues working OK. Also check that the battery voltage drops when the battery test

starts. If the batteries are charged, the voltage should not fall below 23.5 Volts.

10. Cancel the one-hour battery test by briefly pressing the Reset switch.

11. If applicable, ensure the Fault/Defect output contacts are connected to the Fire Alarm ‘External

Defect/Fault input' to ensure that power supply or battery problems can be monitored remotely.

Monitoring System Operation

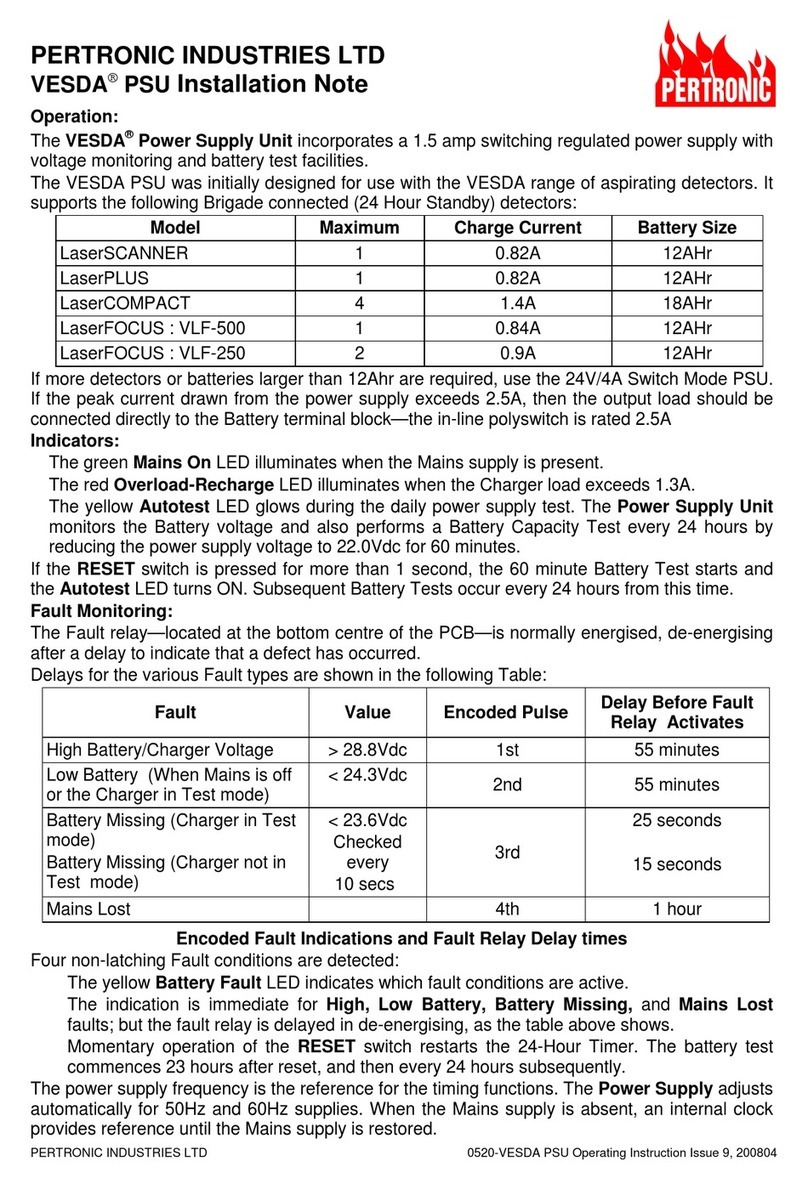

The monitoring system automatically checks the power supply and batteries. There are two separate fault

indicating devices:

The Battery Fault LED flashes in groups of four if any fault has been detected. The fault type is

indicated by the position of long flash(es) in the group (refer to the Fault Table). The LED continues

indicating the fault(s) until either the power supply is powered down, or the Reset switch is

momentarily pressed.

The fault relay contacts change over if any fault is detected. The fault relay is non-latching. If the

fault goes away, the fault relay contacts go back to normal. Note that fault relay indication is

delayed. Refer to the Fault Table for details.

Voltage

During normal operation the monitoring system continuously monitors the power supply output voltage. If the

voltage goes outside the range defined by the high and low charger voltages (refer to Fault Table) the

monitor reports a fault. This function is disabled during the one-hour battery capacity test, and if the mains

power supply is lost.

Battery Connected

Every ten seconds the monitoring system briefly reduces the output voltage of the switched-mode power

supply. If the power supply output voltage falls below the threshold (See Fault Table), the monitoring system

indicates a “Battery Disconnected” fault. This function is disabled if the mains power supply is lost.

Battery Capacity Test

Every 24 hours, the monitoring system initiates a one-hour automatic battery capacity test. During this test,

the switched-mode power supply operates at reduced voltage and the yellow Autotest LED lights. If the

power supply output voltage falls below the threshold (See Fault Table), the monitoring system indicates a

fault. This test does not take place if the mains power supply is lost.