Rev.01

•When power is supplied to the OK-150, the first threshold

LED lights with a frequency of T1 (1Hz), the second

threshold LED lights constantly, the sound is played

monotone (1000 Hz) with rectangular modulation and with a

frequency of 1 Hz (SND5//@square: mod = 1000/0Hz F=1

Hz):

Mode 2 "KEY2" –compatibility with the MU-150 / MU-150E

unit with 5-pin “Horn” connector

The mode in which control occurs by the both “S0” and “S1”

control signals closing them to “GND" (see Fig. 11).

Figure 11. The OK-150’s switches in the “KEY2” mode

In case of connection according to drawing on Fig. 5,

(connection to the MU-150 / MU-150E / MK-140 / MK-

140(GAZ) unit), it becomes possible to control the LEDs

separately, according to the first and second thresholds, as

well as to reproduce a different sound for each threshold.

When power is supplied, the LEDs and the sound alarm will

briefly work, subsequently, with an interval of 1 time per

minute, both LEDs light up briefly, signaling normal operation.

When the control signal “S0” is closed to “GND”, the first

threshold LED and the sound signal corresponding to the first

control signal will work, and when the control signal “S1” is

closed to “GND”, the second threshold LED and the

corresponded sound signal will be engaged in accordance

with the modulation and frequency set by the switches.

Additionally, in the "KEY2" mode there are priorities by input

signals. For example, the operation of LEDs by prioritymeans

that when the control signal “S1” is switched, the previously

activated LED light mode by the control signal “S0” will turn off

and the light mode will be turned on according to the control

signal “S1”.

Examples of switches settings:

•When power is supplied tothe OK-150and the control signal

“S0” is working, the first threshold LED lights constantly, the

sound is played two-tone (800/1000 Hz) with rectangular

modulation and with a frequency of 2 Hz (SND7//@square:

mod = 800/1000 Hz F=2 Hz). When the control signal “S1”

appears, the first threshold LED lights constantly, the

second threshold LED lights constantly, the sound is played

two-tone (800…1000 Hz), with attenuating-increasing

modulation, with frequency 8 Hz (SND8//@ramp: mod =

800...1000 Hz F=8 Hz):

•When power is supplied tothe OK-150and the control signal

“S0” is working, the first threshold LED lights with a

frequency of T1 (1 Hz), the sound is played two-tone

(3000...3400 Hz), with attenuating-increasing modulation,

with a frequency of 1 Hz (SND3//@ramp: mod = 3000...3400

Hz F=1 Hz). When the control signal “S1” appears, the first

threshold LED lights with a frequency of T1 (1 Hz), the

second threshold LED lights with a frequency of T2 (2 Hz),

the sound is played two-tone (3000/3400 Hz), with

rectangular modulation, with a frequency of 2 Hz

(SND4//@square: mod = 3000/3400 Hz F=2 Hz):

Mode 3 "SOFT”

This mode is configured via serial communication using the

program “Platone” or “ThunderFlash” and is needed to select

a specific mode of operation. The program and operating

instructions are available on request.

Mode 4 "TEST”

Cyclic check of light and sound alarm.

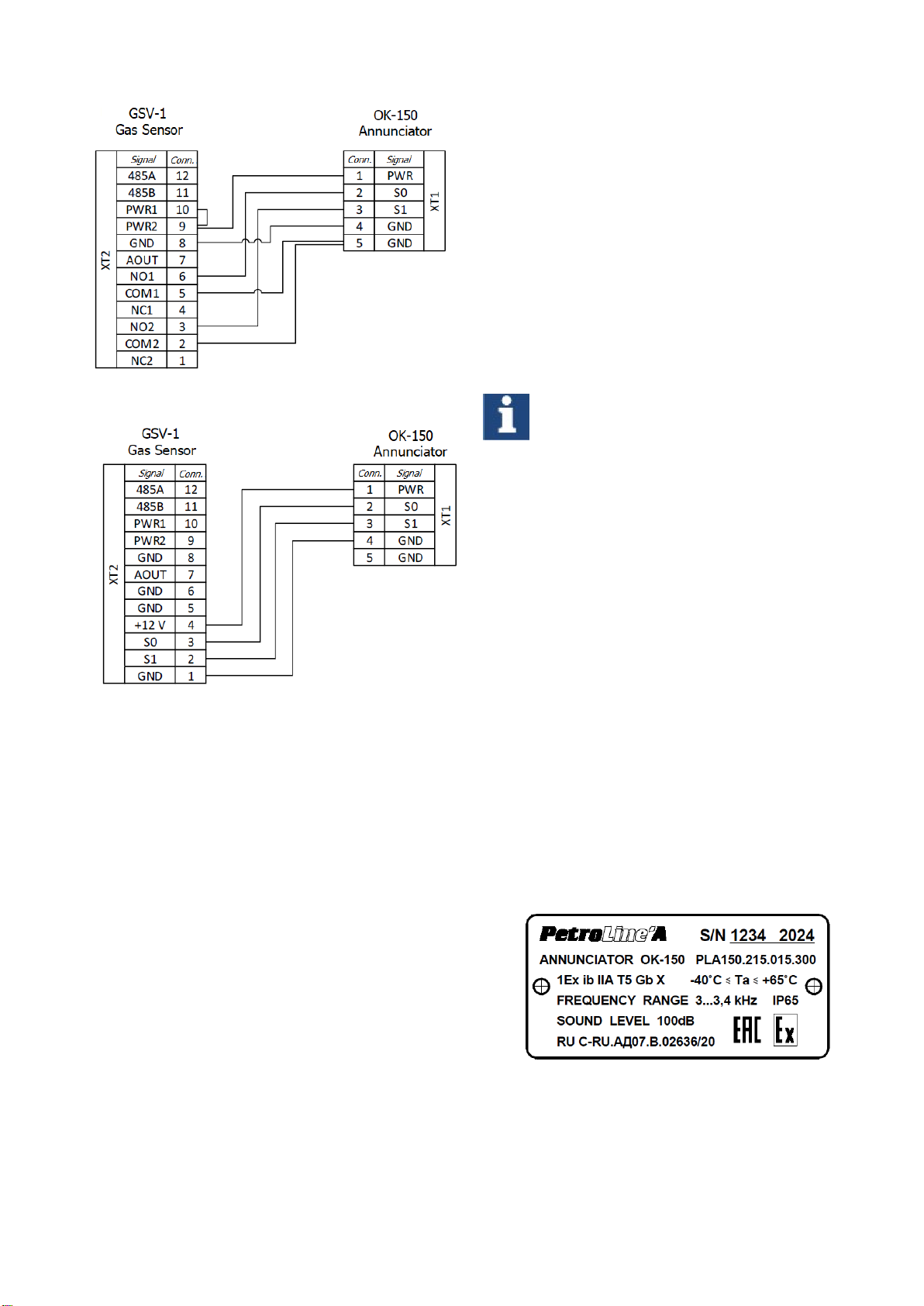

9. Setting of the OK-150 for Operation as a Part of the

GSV-1 Post

To operate the OK-150 annunciator connected to the GSV-1

gas sensor directly and display each threshold with the

corresponding visual and audible alarm, it is necessary to

switch the annunciator over to the Mode 2 "KEY2" and to

connect it to the GSV-1’s connector according to the drawings

on Fig. 12 or 13, depending on the gas sensor’s connector.