Sky Control SC8100 Instruction sheet

Configuration Manual

SC8100

SC8110

Contents

4

5

6

Product description

Document overview

Related documentation

Product options

Installation of appliance

Rack-mount installation

Power cord and network cable connection

Appliance connections

Analog sensors connection

CAN sensors connection

CAN modules connection

1-Wire reader connection

I-Touch Button connection

Proximity reader connection

Relay outputs connection

Connection of loads to SC8100

Connection of loads to SC8110

Backup battery connection

USB camera connection

List of possible USB cameras

Extension units connection

Dry contacts module connection

GSM modem connection

Software upgrades

HTTP upgrade

FTP upgrade

USB upgrade

Restoring appliance settings

Disposal

Battery replacement

Cleaning of appliance

Electrical characteristics

Physical characteristics

Environmental characteristics

Battery backup

Access

Administrator account, user ID and pass-

word

Root account user ID and password

Settings recovery

Password recovery

Quick conguration

Alert actions

Message format

Object map

Timer

Server ping

IP cameras

Groups

Logic schemes

Access control

Sensor conguration

Front panel

Back panel

Inventory

Introduction

Physical Description

Inventory

Installation

Upgrade options

Specications

Warranty

Cleaning, battery disposal and replace-

ment

2

2

2

2

8

9

9

10

10

11

12

13

13

13

21

23

23

23

24

24

24

24

17

18

Initial conguration

Overview

Default network settings

Network settings conguration

How to nd out your IP address

16

23 Warranty period

Introduction

Introduction

Product description

Sky Control appliances - monitoring units

SC8100 and SC8110 - are the main Sky Control

modules for monitoring and environmental

control. These main modules have 8 analog

ports for connecting Sky Control analog sensors,

2 CAN ports for connecting CAN digital sensors

and/or CAN expansion modules and 1-Wire port

for connecting a 1-Wire reader.

Document overview

The Installation and Quick Conguration Manual

describes how to install Sky Control modules

SC8100, SC8110, as well as how to connect

the module and to congure the network set-

tings. After performing conguration procedures

described in this manual, you can access the

system from Firefox and Chrome browser, per-

form additional conguration tasks and begin to

monitor the environment.

Analog sensors

Temperature sensor

(SC500)

Outdoor temperature

sensor (SC501)

Humidity sensor

(SC510)

AC voltage monitor

(SC520)

Access sensor (SC530)

Vibration sensor

(SC540)

Smoke sensor (SC560)

Related documents

Unless otherwise noted, the following documen-

tation is available on the CD provided with the

device or on the web page: www.skycontrol.

com. Sky Control User Guide contains all the

information on the operation, management,

and Sky Control system setup for one of the

following main modules: SC8100, SC8110. For

support please visit our forum at: www.forum.

skycontrol.com

Product options

The following options are available for the appli-

ance. For more information on any of these op-

tions, contact your Sky Control distributor from

which you have purchased Sky Control product.

2

Introduction

Analog sensors

PIR sensor (SC570)

Leak sensor (SC590)

Cable leak sensor

(SC591)

Current loop converter

4-20 mA (SC420)

CAN modules

Airow and tempera-

ture control CAN unit

(SC450) with water

leak cable (SC559)

Modules

Dry contacts unit

(SC16)

GSM modem (SC920)

CAN sensors

PIR, vibration, tem-

perature CAN sensor

(SC470)

Smoke, humidity and

temperature CAN sen-

sor (SC460)

3

Physical Description

Physical Description

1“LAN” - Ethernet 10/100 Base-T port,

provides Ethernet connection. LEDs - “yel-

low” (status) and “green” (trafc) shows

the network trafc. The status LED: ashes

green when system starts up, shows the

connection state (constant green light - the

connection is established, blinking green -

the connection attempt).

2“USB” - type A USB-port 2.0, is required

for USB ash drive to upgrade an appli-

ance.

3“HS” - type miniAB USB-port 2.0, required

to connect a USB camera or to restore an

appliance.

4“Reset” - resets the appliance.

5“SD” - SD card connector with ejector,

needed to store data.

6LEDs: “ACT” - indicates appliance status,

“CN1” - indicates CAN1 bus trafc, “CN2” -

indicates CAN2 bus trafc, “ERR»” - indi-

cates error and trafc.

7“CAN” - two equivalent digital connectors

RJ12 for the connection of CAN sensors

and CAN extensions on a CAN bus, with

auto-sensing.

8“TR” - CAN terminator, required for a con-

nection of large amount of sensors or for

long distance connection of CAN sensors.

9“A1..A8” - 8 RJ12 analog sensor inputs

with auto-sensing.

10 “SIM” - connector with an ejector, used

when GSM modem is installed inside of the

appliance to connect SIM card.

11 “Outputs 1..4” - 4 relays status indicators.

12 “1-Wire” - RJ9 connector for 1-Wire Prox-

imity type or I-touch readers with auto-

sensing.

13 “SMA” - connector, used when GSM mo-

dem is installed inside of the appliance to

connect GSM antenna.

Front panel SC81xx

4

Physical Description

5

Back panel SC8100

Back panel SC8110

14 “AC line” - power input 240V. IEC C14 con-

nector.

15 “Fuse” - 0.2A type 5*20

16 “Output 1..4” - AC output voltages from re-

lays. Connector IEC C13. Maximum output

power for each relay - 10A*240V.

17 “RLY1...RLY4” - 4 relays output connectors.

The relays maximum power output - 5A *

240V.

18 “SMA” - optional hole for mounting SMA

antenna of GSM modem.

19 “DC 12V” - backup power socket, to con-

nect a battery or a battery backup.

20 “Dry contacts” - empty slot for dry contacts

module SC16, used to connect dry con-

tacts on doors, windows, etс.

Inventory

Inventory

Make sure that the contents of the delivery

meet the following conguration. Report a miss-

ing or damaged component to your supplier. If

damage occurred during transportation, contact

the appropriate delivery service.

Inventory

Description

Monitoring unit SC8100.

19” rack brackets - 2 pcs.

M3 x 8 Phillips at-head

screws - 6 pcs.

Self-adhesive rubber foot

- 4 pcs

Description

1.8-m NEMA 5-15P to

IEC-320-C13 power cord

1.8-m NEMA 5-15P to

IEC-320-C13 power cord

only SC8110

RJ45 1m patch cable

USB-miniUSB cable

Backup battery 3.5mm

terminal plug

6

Inventory

Description

Relay terminal plug 5.08

mm - 1 pc

only SC8100

Relay terminal plug 5.08

mm - 1 pcs

only SC8100

CD-ROM with documen-

tation and software

Conguration manual

Warranty card

7

Installation

Installation

When installing the unit in a 19” rack,

make sure that there is no uneven me-

chanical loading so as not to create a dangerous

situation. You should not use the unit as a shelf

or hang it uncommitted.

Rack mount installation

Select a place of unit installation inside the rack.

The system takes up 1U of rack. Set to the

desired location and tighten the bolts on the

spacer nuts.

To avoid equipment damage fasten all the

screws all the way!

Do not connect the device to ungrounded

outlets! Check the outlet and make sure

they are grounded when using the extension

cords.

Before applying power to the device, read

its electrical characteristics in order to

avoid the power supply circuit overloading.

Power cable and Network cable con-

nection

8

Installation of appliance

The unit can be installed in the front or rear of

the rack, or can be put on the shelf using self-

adhesive rubber feet. It takes up 1U of 19” rack!

When installing, consider the following condi-

tions:

nect approved devices to ports on the unit as di-

rected in this manual. Plugging in other devices

may result in equipment damage.

Connect the unit only after checking the

grounding of the circuit.

You must install the unit in place, where

the ambient temperature corresponds to

the values listed under “Specications”. Keep in

mind that the temperature of the unit increases

in cramped conditions, please keep track of the

temperature on the internal temperature sensor.

Try to install the unit in such a way as to allow

for normal air circulation required for the normal

functionality of the unit.

Do not connect homemade sensors and devices

with unknown functions to the unit! Only con-

Installation

1Connect the appropriate power cord to the

unit AC line input.

2Connect unit’s LAN port using network

cable to the switch.

Analog sensors connection

This procedure applies to the following sensors,

which are supported by the appliance and are

connected to the analog ports:

Icon Analog sensors

Temperature sensor (SC500)

Outdoor temperature sensor

(SC501)

Humidity sensor (SC510)

Voltage detector (SC520)

Access sensor (SC530)

Smoke sensor (SC560)

Appliance connections

3Plug the power cable into the power

source.

9

Icon Analog sensors

Cable leak sensor (SC591)

Vibration sensor (SC540)

Current Loop transceiver (SC420)

PIR sensor (SC570)

Leak sensor (SC590)

Installation

Connect analog sensor by a supplied RJ-11

(6P4C) cable to any analog port A1 .. A8 on the

appliance. Determination of the sensor type and

connection will occur automatically.

If strong electromagnetic interferences

are present, we recommend to use 3-pair

cable CAN FTP for sensor connection!

Sensors are shown on p. 2-3.

CAN sensors connection

This procedure applies to the following sensors,

which are supported by the appliance and are

connected to the CAN ports:

Icon CAN sensors

Smoke, temperature and hu-

midity sensor (SC460)

PIR, temperature and vibration

sensor (SC470)

Sensors are shown on p. 3.

Connect CAN sensors to any CAN port CN1 or

CN2 on the appliance using an FTP CAN RJ-

12(6P6C) cable supplied. CAN sensors can also

be connected to the port of another Sky Control

CAN sensor or CAN device connected to appli-

ance by CAN bus. Determination of the sensor

type and connection will occur automatically.

You can connect up to maximum 40 digit-

al CAN sensors and CAN devices together

to one CAN port!

CAN modules connection

This procedure applies to the following CAN

devices, which are supported by the appliance

and are connected to the CAN ports:

Icon CAN modules

Airow unit (SC450)

Using FTP CAN RJ-12(6P6C) cable supplied,

connect CAN device to any CAN port CN1 or

CN2 on the appliance, or to the port of another

Sky Control CAN sensor or CAN device con-

nected to appliance by CAN bus. Determination

You can connect up to maximum 40 digit-

al CAN sensors and CAN devices together

to one CAN port!

10

Installation

1-Wire reader connection

I-Touch or 1-Wire Proximity readers can be con-

nected using RJ9 (4P4C) connector via input “1-

Wire” of an appliance. The reader is determined

automatically.

of the device type and connection will occur

automatically.

I-Touch Button connection

Readers I-BUTTON have two wires.

1Ground (GND)

2Data wire (BUS)

I-BUTTON reader ground is connected to the

GND pin on RJ9 connector. Data wire of I-

BUTTON reader is connected to the BUS contact

on RJ9 connector.

11

Proximity reader connection

Proximity Readers have 3 wires:

1Power (+12V)

2Data wire (BUS)

3Ground (GND)

Proximity reader’s GND is connected to the GND

pin on RJ9 connector. Proximity reader’s data

wire is connected to the BUS contact. Proximity

reader’s power connects to the +12V pin on RJ9

connector.

Relay outputs connection

Each appliance has the possibility to connect up

to 4 loads managed by built-in relays . In the

case of SC8100 built-in relays have independent

separate entrances and exits. In case of SC8110

Connection of loads to SC8100

To connect an external load, connect the wires

from the external power supply to the appropri-

ate medium (2) clamps of the relay terminal

plug, the load to the left (1) or right (3) clamps

of the plug. Insert the plug into the relay socket

terminal RLY1 ... RLY4. By command, relay will

switch on or off the load. The maximum pos-

sible output current of the relay - 5A.

appliance, power is applied to all inputs of 4

built-in relays.

12

Installation

The appliance uses latching relays, when

power on appliance switches on/off, relays

remain in command position!

Do not insert the terminal plug into the

relay terminal socket RLY1 ... RLY4 when

external voltage source is turned on.

Connection of loads to SC8110

To connect an external load, сonnect NEMA

power cable from the load to the output “Output

1 .. 4” of the appliance. By command, relay will

switch on or off the load.

The maximum possible total input current to 4

relays - 10А. The maximum current load on the

relay - 5А.

To avoid breakage, do not connect the

relays loads when the appliance is turned

on.

Backup battery connection

If necessary, connector “DC 12V” can be con-

nected to the backup battery 10-12 V with sup-

plied plug 3.5 mm. Battery discharge starts as

the battery voltage exceeds over the appliance

USB camera connection

If necessary, by means of attached cable USB-A

/ MiniUSB AB, you can connect any USB camera

of class Linux UVC Webcam to connector “HS”.

Determination of camera and connection will

occur automatically.

List of possible USB cameras

We recommend:

1Logitech С160, Logitech С270, Logitech

С510

Extension units connection

To install and to connect extension units: switch

off appliance, unplug from the outlet or discon-

nect the power connector. Carefully unscrew

three screws holding the cover and open it.

Dry contacts module connection

1Break 4 steel bridges in the dry contacts

hole of the appliance case. Using forceps

cut the thin bridges in the hole. Make sure

that no burrs are left.

13

Installation

Do not use backup batteries if their freshly

charged voltage exceeds 12.6 V!

internal voltage 12V.

GSM modem connection

Inventory

GSM board Antenna

Antenna wire BH16 cable

2

3

4

Inventory

Dry contacts board BH10 cable

Relay terminal plugs Screw M3*5

1

2Set up dry contacts module on 3 steel

spacing sleeves inside the appliance case,

attach the board with three M3 screws

from supply to the sleeves.

3Connect 10-pin at cable to the connector

on the module card and on the appliance

motherboard. Close and fasten the cover.

4If necessary, connect dry contacts to the

module with appropriate 3.5 mm terminals

from supply.

14

Installation

1Connect antenna cable to the modem card.

Carefully connect the U-Fl antenna cable to

the input U-FL connector and gently press

it. If possible install the connector on the

seat with a magnifying glass!

3Set the SMA connector antenna cable to

the rear or to the front panel of the appli-

ance into the corresponding SMA hole. Put

on the SMA connector gold-plated washer

and nut from the supply, holding SMA con-

nector with one key, securely tighten the

nut with the other key.

Do not tighten SMA connector with one

key, you can break the cable and the con-

nection would be lost!

4Connect 16-pin at cable to the connectors

on the modem card and on the appliance

motherboard. Close and fasten the cover.

If necessary, install the SIM card into the

appropriate hole.

2

3

4

2Set up the GSM modem card on 3 steel

spacing sleeves on the cover, attach card

to the sleeves using three M3 screws sup-

plied with the modem.

1

Inventory

3 винта М3*5

15

Installation

Initial Conguration

Overview

You must congure the following TCP/IP settings

before the appliance can operate in a network:

1IP-address of device

2Netmask

3Gateway

If a default gateway is unavailable, use the IP

address of a server that is located in the same

subnet as the appliance and that is usually run-

ning. The appliance uses the default gateway to

test the network when trafc is very low.

Please use only Firefox and Chrome like

web-browser. Interface is incompatible

with IE.

In the appliance interface open the folder “Set-

tings”, then go to the folder “Network”. Fill or

change the elds “IP address”, “Netmask”, and

if nesessary “Gateway”, “Primary DNS” and click

“Update”.

Default network settings

Default network settings of appliance are:

1IP-address: 192.168.0.193

2Netmask: 255.255.255.0

3Other parameters are not set

Network settings conguration

If you accidentally lost the IP address of your

current appliance and you need to know it,

simply connect an empty USB-ash drive to

the appliance USB connector, the system will

automatically copy the le “dumplog” with some

settings (including IP-address) onto the ash

drive. Wait until the ash drive blincks and goes

off, unplug it, plug it into your PC and read the

le “Dumplog” using any text editor. Appliance

How to nd out your IP adress

Start >> Control panel >> Network Con-

nections >> Right mouse click on Local

Area Connection >> Properties >> Internet

Protocol (TCP/IP)

To start working with the appliance your

PC must have subnet and subnet mask

compatible with new appliance! Use your PC

with any permitted IP-address: 192.168.0.XXX,

where XXX = number from 0 to 192, and sub-

net mask: 255.255.255.0.

16

Initial Conguration

Access

An appliance has a pre-congured administrator

ID “guest”. When appliance is turned on for the

rst time , ID and password are not required.

If you see no information on the screen, go to

the folder “System menu”, then go to the folder

“Login user”, type: guest and press “OK”.

Administrator account, user ID and

password

To improve security, change the adminis-

trator account ID.

Root account user ID and password

An appliance has a pre-congured account iden-

tier - “guest” and any user can log in. To add a

new user, enter a new ID or modify an existing,

it is necessary to mark the user rights on “read”

and “write”. The administrator can restrict the

ID “guest” read and write privileges, or at all

To prevent users from seeing other identi-

ers, it is compulsory to remove the check

mark from the eld “Access Control”!

Settings recovery

The appliance has the ability to save settings to

the backup le and restore it later. To save a le

with the system settings, follow these steps: in

the appliance interface go to the folder “System

menu”, select menu item “Save settings”, click it

and save le “sky25settings.sky”.

To restore, to change or to clone settings, copy

the le “sky25settings.sky” to the root of a USB-

ash drive, without changing the le name. Plug

the USB ash drive into the appliance socket

“USB” and wait. The update process is displayed

on the front panel with ashing LED “ERR”.

If successful, the “ERR” LED will go off, and

“ACT” LED will blink for a while with increased

frequency. If unsuccessful “ERR” LED will remain

lit. Test the appliance.

IP-address will be in the rst lines of this le.

In the appliance interface go to the folder “Pref-

erences”, then go to the folder “Users”. Change

ID “guest” on the required administrative login

ID or enter a new administrator login with “read

and write” privileges: “All” and “All”. To log in,

use only the login ID, password is not required.

17

Initial Conguration

remove this ID. In this case, third-party users

can not log into the system. To add a new user,

administrator needs to enter a new ID, and it is

necessary to mark read and write privileges.

Password recovery

Sometimes, in case of loss of all the data on

the appliance or if you have equipment with

unknown settings, it is may be necessary to re-

store the password identier and change it to a

“guest”. Use the le “sky25resetusers.sky”, copy

this le to the root of a USB-ash drive, without

changing the le name. Plug the USB ash drive

into the appliance socket “USB” and wait. The

update process is displayed on the front panel

with ashing LED “ERR”. If successful, the “ERR”

LED will go off, and “ACT” LED will blink for a

while with increased frequency. If unsuccessful

“ERR” LED will remain lit.

%4

--

%1

--

%2

--

%3

Quick Conguration

Turn on the appliance, set up the network set-

tings, proceed to congure other settings and

actions.

In order to add recipients of notications, go to

the upper left corner of the appliance web inter-

face, go to the tab “Add”, select the appropriate

menu item and click. You can add E-mail with

item “Add Mailer - Email”, - SNMP trap with item

“Add Mailer - SNMP trap”, - SMS address with

item “Add Mailer - SMS”, ll in the appropriate

elds and save.

To test the recipients address notications you

can use the item “Send test message”.

Alert actions

The format of the message can be specied by

the administrator as follows:

In such case you may get the following mes-

sage:

Message format

Logic scheme name

--

if ‘S/N iButton’(id=13) in state ‘alarm’,

then

‘Email’(id=302) changes to state ‘on’ im-

mediately

‘Relay-0’(id=31) changes to state ‘pulse’

immediately

--

‘S/N iButton’(id=13) in state ‘alarm’

--

12:40:36 2012/01/18

By default, a map of some object is shown in

the appliance interface. To change the map, go

to the folder “System menu”, click on the item

“Add picture map” and change it.

Object map

Macros Description

%1 Description of the logic scheme that

came into action (see below).

%2 Sensor data, included in the logic

scheme.

%3 Time of response of the logic

scheme.

%4 Name of logic scheme

18

Initial Conguration

We advise to use a more informative way

of writing down the instructions:

Logic %4:

--

Denition:

%1

Current sensor state:

%2

--

System time: %3

Other manuals for SC8100

1

This manual suits for next models

1

Table of contents

Popular Security System manuals by other brands

Thermo Scientific

Thermo Scientific Smart Siren user guide

SpeedTech Lights

SpeedTech Lights BOSS S-BDT200 instruction manual

Tynetec

Tynetec Altec Response installation guide

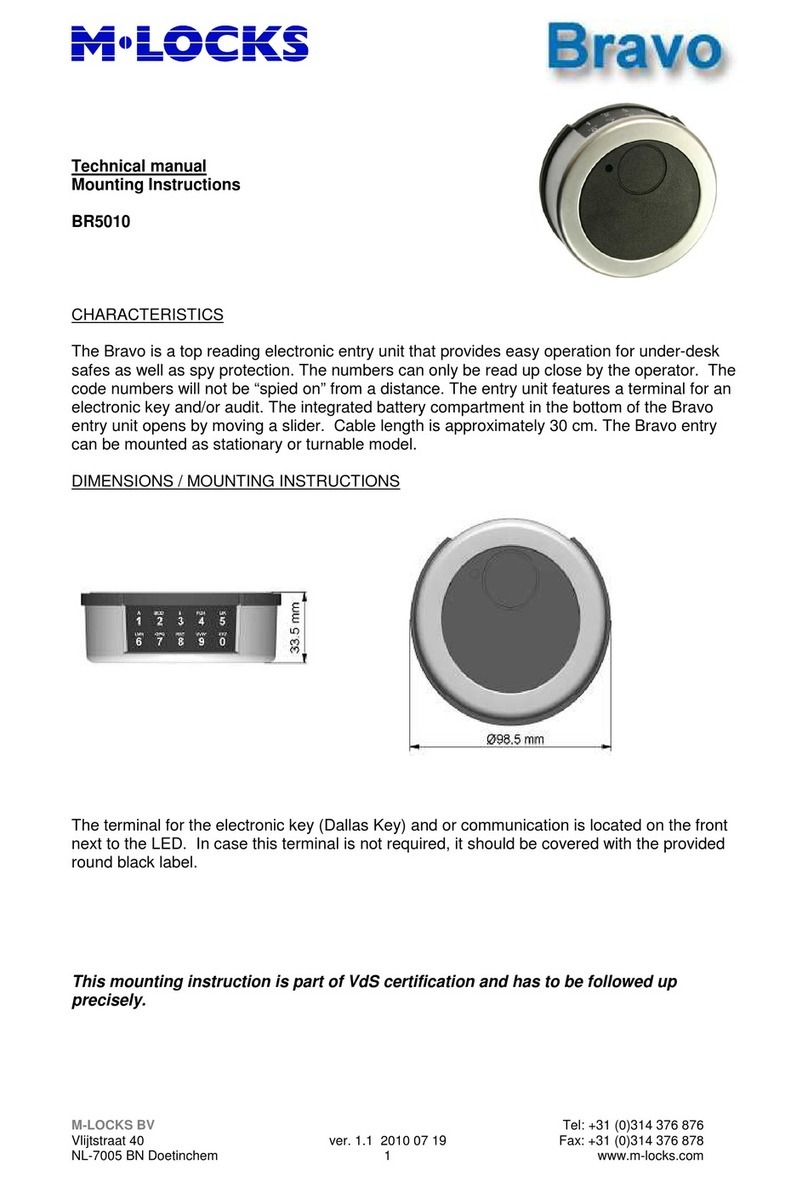

M-LOCKS

M-LOCKS Bravo BR5010 Technical manual

Honeywell

Honeywell Domonial user manual

Microjack

Microjack MicroJack MP2016 user manual