Page 3

Pettibone Michigan, L.L.C. OWNER/OPERATOR MANUAL MODEL 6036/6044/8036/8044

(Continued on next page)

continued from previous page

INTRODUCTION .............................................................................................................................. 46

IDENTIFICATION .................................................................................................................................. 46

FORKLIFT IDENTIFICATION PLATE ................................................................................................ 46

ENGINE IDENTIFICATION PLATE .................................................................................................... 46

TRANSMISSION IDENTIFICATION PLATE...................................................................................... 46

AXLE IDENTIFICATION PLATE LOCATION ................................................................................... 46

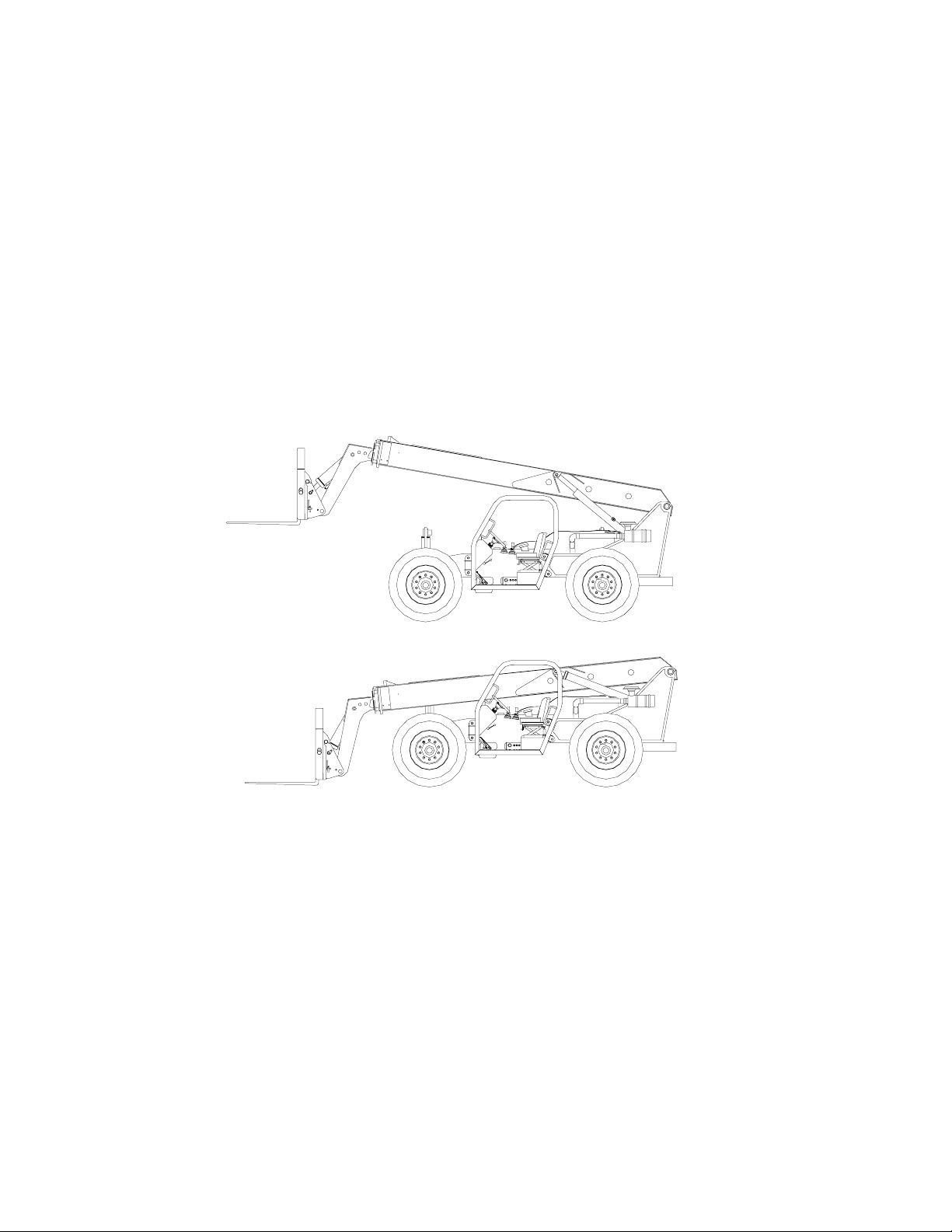

EQUIPMENT DESCRIPTION ............................................................................................................... 48

FORKLIFT DESCRIPTION .................................................................................................................... 48

STANDARD ENGINE DESCRIPTION ................................................................................................. 48

TRANSMISSION DESCRIPTION ........................................................................................................ 48

AXLE DESCRIPTION ............................................................................................................................ 48

OPTIONS ................................................................................................................................................. 48

OPERATION .......................................................................................................................................... 51

Operators Seat ................................................................................................................................... 51

Entering the Operators Compartment ............................................................................................... 51

Seat Suspension Adjustment (optional).............................................................................................. 51

Arm Rest ............................................................................................................................................. 51

Seat Belt.............................................................................................................................................. 52

Instrument Panel ................................................................................................................................. 53

Fuel Gauge.......................................................................................................................................... 53

Engine Coolant Temperature Gauge .................................................................................................. 53

Engine Coolant Temperature Warning Light (Optional) ................................................................... 53

Inclinometer........................................................................................................................................ 55

Parking Brake Switch ......................................................................................................................... 55

Clutch Cut-off Switch ........................................................................................................................ 55

Axle Lock Warning Light .................................................................................................................. 55

Brake Oil Pressure Warning Light .................................................................................................... 55

Park Brake Indicator Light ................................................................................................................. 55

Low Voltage Warning Light .............................................................................................................. 55

Engine Oil Pressure Warning Light ................................................................................................... 56

Ignition Switch ................................................................................................................................... 56

Steering Selector................................................................................................................................. 56

Hydraulic Controls ............................................................................................................................. 57

Throttle and Brake Controls ............................................................................................................... 58

Transmission Controls ........................................................................................................................ 59

CHECK TRANSMISSION OIL .............................................................................................................. 60

CHECK HYDRAULIC FLUID LEVEL ................................................................................................. 61

TIRES AND RIMS .................................................................................................................................. 61

INSPECTION FOR LEAKS .................................................................................................................... 62

GENERAL INSPECTION ....................................................................................................................... 62

GAUGES AND INDICATORS ............................................................................................................... 62

HYDRAULIC FLUID LEVEL ................................................................................................................ 62

CHANGES IN PERFORMANCE ........................................................................................................... 62

TABLE IV. TIRE PRESSURES ............................................................................................................. 62