Index

Contents ..................................................................................Page

1Safety .................................................................................................................................... 5

1.01 Directives .............................................................................................................................. 5

1.02 General notes on safety......................................................................................................... 5

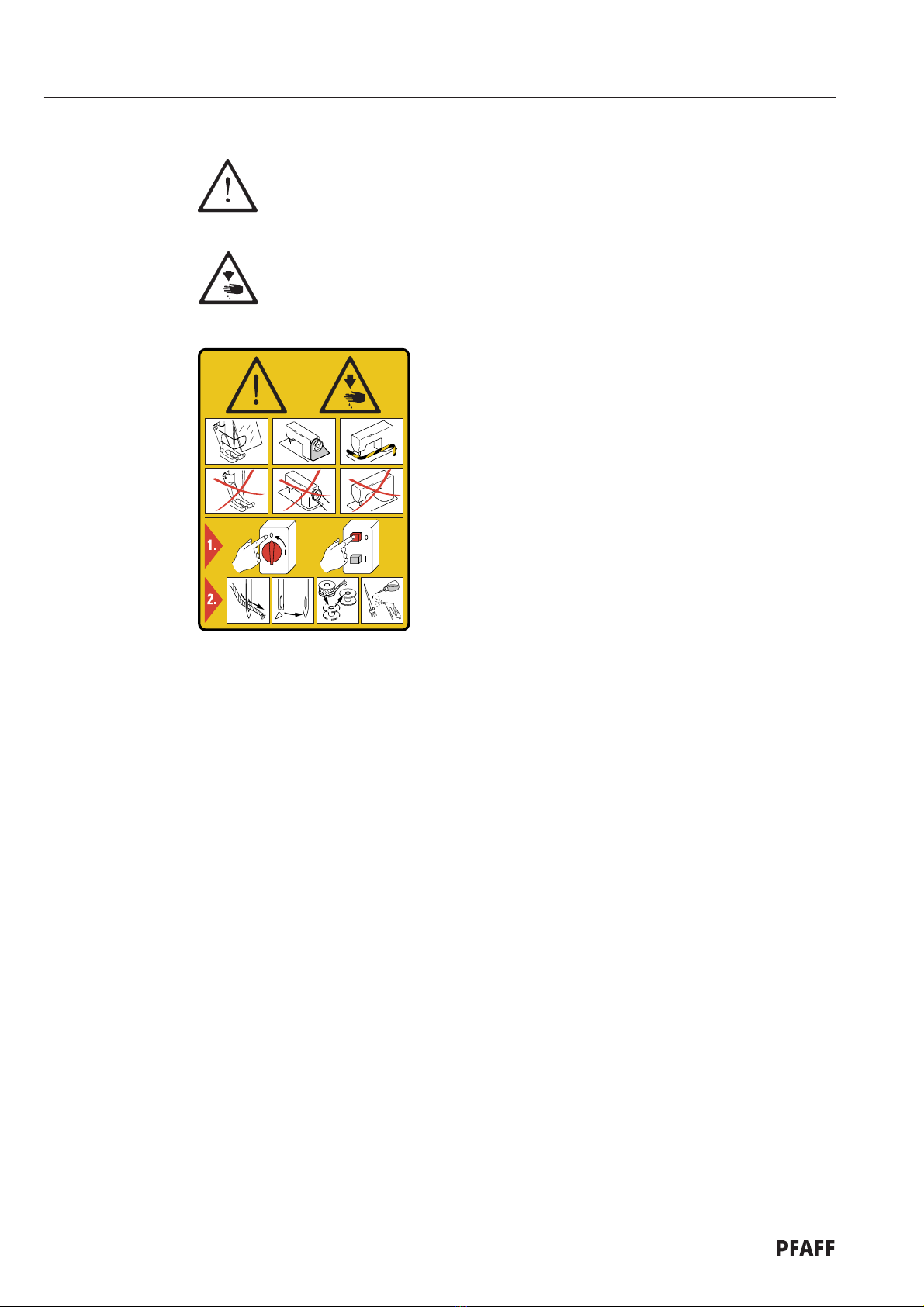

1.03 Safety symbols ...................................................................................................................... 6

1.04 Important points for the user................................................................................................. 6

1.05 Operating and specialist personnel........................................................................................ 7

1.05.01 Operating personnel .............................................................................................................. 7

1.05.02 Specialist personnel............................................................................................................... 7

1.06 Danger ................................................................................................................................... 8

2Proper use ............................................................................................................................ 9

3Specifications ..................................................................................................................... 10

3.01 General specifications.......................................................................................................... 10

3.02 Versions and subclasses...................................................................................................... 11

4Disposal of Machine .......................................................................................................... 12

5Transportation, packing and storage ................................................................................ 13

5.01 Transportation to customer‘s premises ............................................................................... 13

5.02 Transportation inside the customer‘s premises................................................................... 13

5.03 Disposal of packing materials ..............................................................................................13

5.04 Storage ................................................................................................................................ 13

6Explanation of symbols..................................................................................................... 14

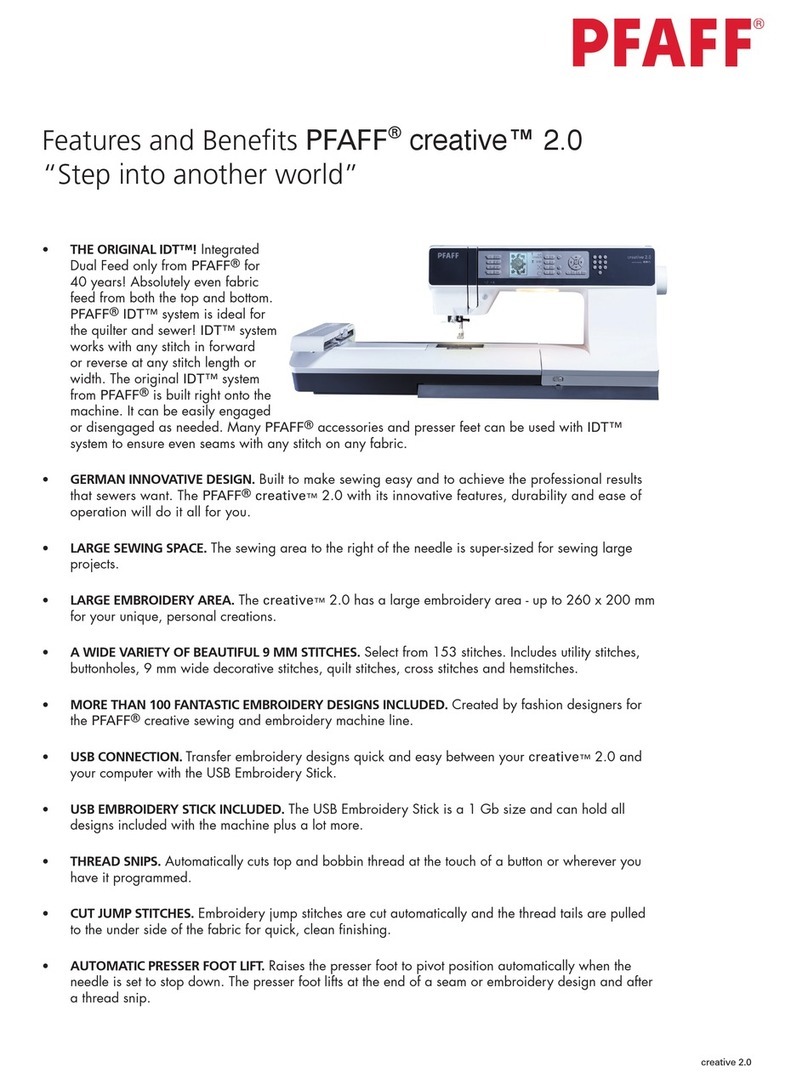

7 Controls............................................................................................................................. 15

7.01 On/off switch ....................................................................................................................... 15

7.02 Key on the machine head..................................................................................................... 15

7.03 Pedal .................................................................................................................................... 16

7.04 Lever for lifting the presser foot........................................................................................... 16

7.05 Knee lever ............................................................................................................................ 17

7.06 Reverse feed key ................................................................................................................. 17

7.07 Stitch length adjustment wheel ........................................................................................... 18

7.08 Adjustment key for limiting the reverse stitch length .......................................................... 18

7.09 Thread wiper switch (only on machines with thread wiper -909/93) ................................... 19

7.10 Control panel........................................................................................................................ 20

7.10.01 Screen displays .................................................................................................................... 20

7.10.02 Function keys ....................................................................................................................... 20

8Installation and commissioning ....................................................................................... 23

8.01 Installation............................................................................................................................ 23

8.01.01 Adjusting the table height.................................................................................................... 23

8.01.02 Assembling the oil pan ........................................................................................................ 24

8.01.03 Mounting the sewing head.................................................................................................. 25