Contents

Contents ................................................................................. Chapter - Page

1Safety ........................................................................................................................... 1 - 1

1.01 Regulations ................................................................................................................... 1 - 1

1.02 General notes on safety ................................................................................................ 1 - 1

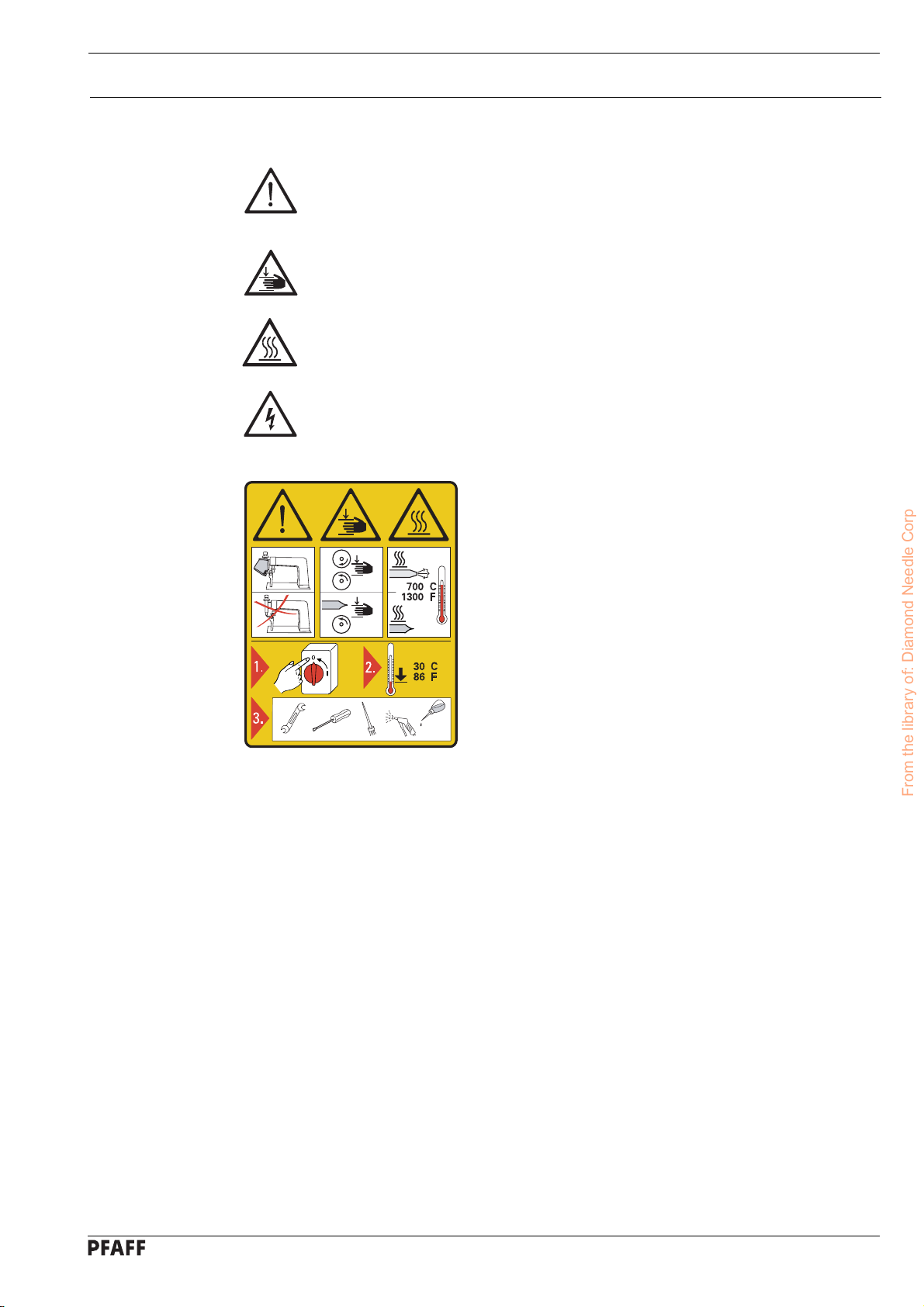

1.03 Safety symbols ............................................................................................................. 1 -2

1.04 Important points for the user ........................................................................................ 1 - 2

1.05 Operating and technical personnel ................................................................................ 1 - 3

1.05.01 Operating personnel...................................................................................................... 1- 3

1.05.02 Technical personnel ...................................................................................................... 1- 3

1.06 Danger warning ............................................................................................................. 1 -4

2Proper use.................................................................................................................... 2 -1

3Specifications .............................................................................................................. 3 - 1

4Disposal of the machine ............................................................................................. 4 - 1

5Transport, packing and storage ................................................................................. 5 - 1

5.01 Transport to the customer’s premises .......................................................................... 5 - 1

5.02 Transport within the customer’s premises.................................................................... 5 - 1

5.03 Disposal of packing ....................................................................................................... 5 - 1

5.04 Storage ......................................................................................................................... 5 - 1

6Explanation of the symbols ........................................................................................ 6 - 1

7Controls ....................................................................................................................... 7- 1

7.01 Main switch ..................................................................................................................7- 1

7.02 Foot switch ................................................................................................................... 7 - 1

7.03 Knee switch (only on machines with tape-cutting device) ............................................. 7 - 2

7.04 Temperature regulator / fault indicator .......................................................................... 7 - 2

7.05 Status display of temperature control ........................................................................... 7 - 3

7.06 Regulator for drive roller start delay .............................................................................. 7 - 3

7.07 Tape feed regulator/hot-sealing speed .......................................................................... 7 - 4

7.08 Selection switch for operational modes ........................................................................ 7 - 4

7.09 Regulator for hot-air pressure ....................................................................................... 7 - 5

7.10 Regulator for feed roller pressure ................................................................................. 7 - 5

7.11 Penetration depth adjustment ring ................................................................................ 7 - 6

7.12 Tape feed regulator / time delay after trimming ............................................................ 7 - 6

From the library of: Diamond Needle Corp