Contents

Contents ..................................................................................Chapter - Page

1Safety ............................................................................................................................ 1 - 1

1.01 Directives ...................................................................................................................... 1 - 1

1.02 General notes on safety ................................................................................................. 1 - 1

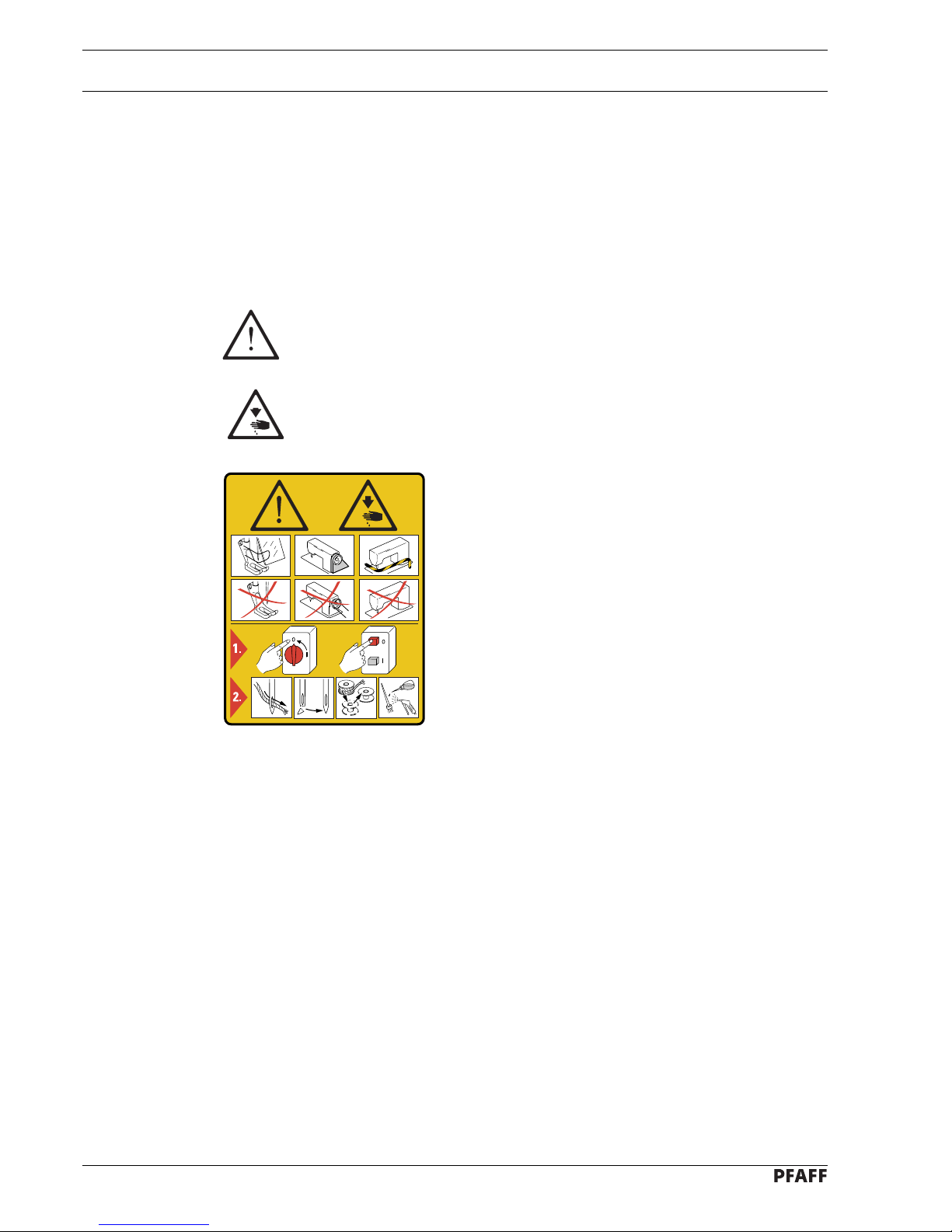

1.03 Safety symbols ............................................................................................................. 1 -2

1.04 Important points for the user.......................................................................................... 1 - 2

1.05 Important points for the user.......................................................................................... 1 - 3

1.05.01 Operating personnel ....................................................................................................... 1 - 3

1.05.02 Operating personnel ....................................................................................................... 1 - 3

1.06 Danger ........................................................................................................................... 1 - 4

2Proper use .................................................................................................................... 2 -1

3Specifications .............................................................................................................. 3 - 1

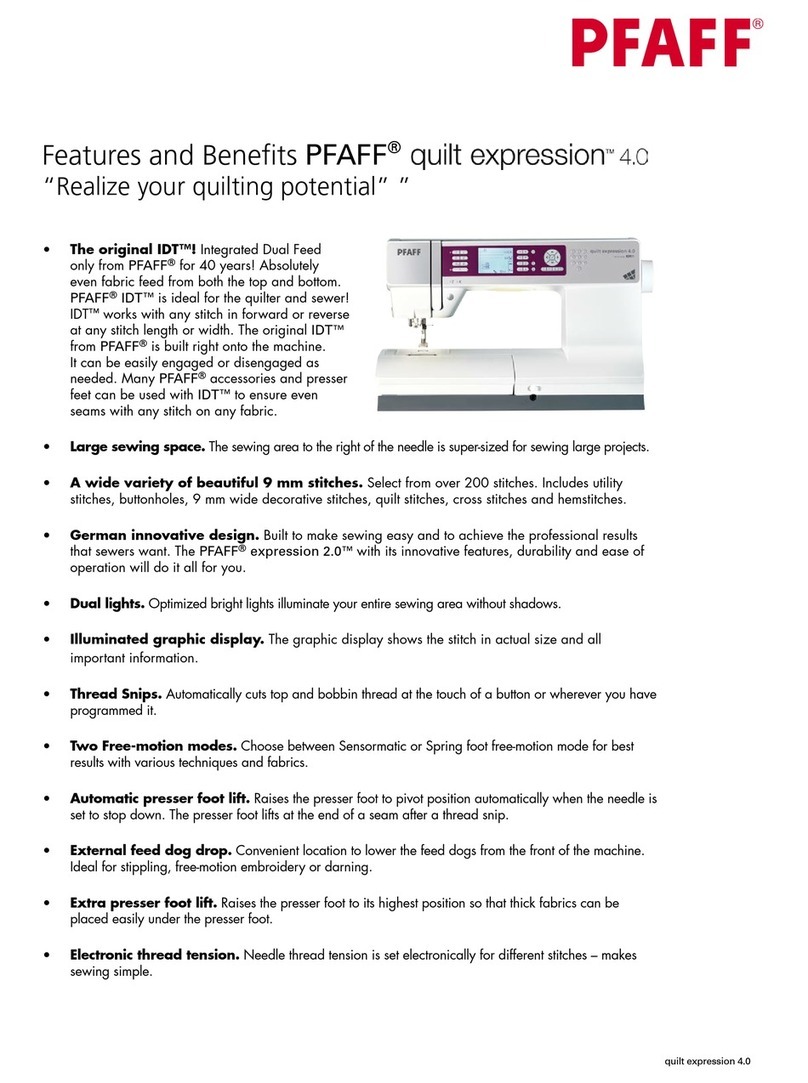

3.01 PFAFF 9063 ...................................................................................................................3- 1

3.02 Models and subclasses ................................................................................................. 3 - 1

4Disposal of machine .................................................................................................... 4 - 1

5Transport, packaging and storage .............................................................................. 5 - 1

5.01 Transport to the customer’s premises ........................................................................... 5 - 1

5.02 Transport within the customer’s premises ..................................................................... 5 - 1

5.03 Disposal of the packaging .............................................................................................. 5 - 1

5.04 Storage .......................................................................................................................... 5 - 1

6Explanation of the symbols ........................................................................................ 6 - 1

7Controls........................................................................................................................7- 1

7.01 On/Off switch ................................................................................................................7- 1

7.02 Pedal ............................................................................................................................. 7 - 1

7.03 Lever for raising the presser foot ................................................................................... 7 - 2

7.04 Knee lever ..................................................................................................................... 7 - 2

7.05 Stitch length adjustment wheel ..................................................................................... 7 - 3

7.06 Stitch length adjustment wheel ..................................................................................... 7 - 3

7.07 Key on machine head .................................................................................................... 7 - 4

7.08 Switch for thread wiper –909/93 .................................................................................... 7 - 4

8Mounting and commissioning the machine .............................................................. 8 - 1

8.01 Mounting ....................................................................................................................... 8 - 1

8.01.01 Adjusting the table-top height ........................................................................................ 8 - 1

8.01.02 Fitting the oil pan ........................................................................................................... 8 -2

8.01.03 Mounting the sewing head ............................................................................................ 8 - 3

8.01.04 Mounting the balance wheel .......................................................................................... 8 - 3

8.01.05 Tightening the V-belt ...................................................................................................... 8 - 4

8.01.06 Mounting the thread winder ........................................................................................... 8 - 5

8.01.07 Mounting the top V-belt guard ........................................................................................ 8 - 6

8.01.08 Mounting the bottom V-belt guard .................................................................................. 8 - 7

8.01.09 Fitting the thread guide .................................................................................................. 8 - 7

8.01.10 Mounting the spool holder.............................................................................................. 8 - 8

8.01.11 Connecting the plug connections and earth cable .......................................................... 8 - 8