Table of Contents

Contents ..................................................................................Page

1Safety .................................................................................................................................... 5

1.01 Directives............................................................................................................................... 5

1.02 General safety instructions .................................................................................................... 5

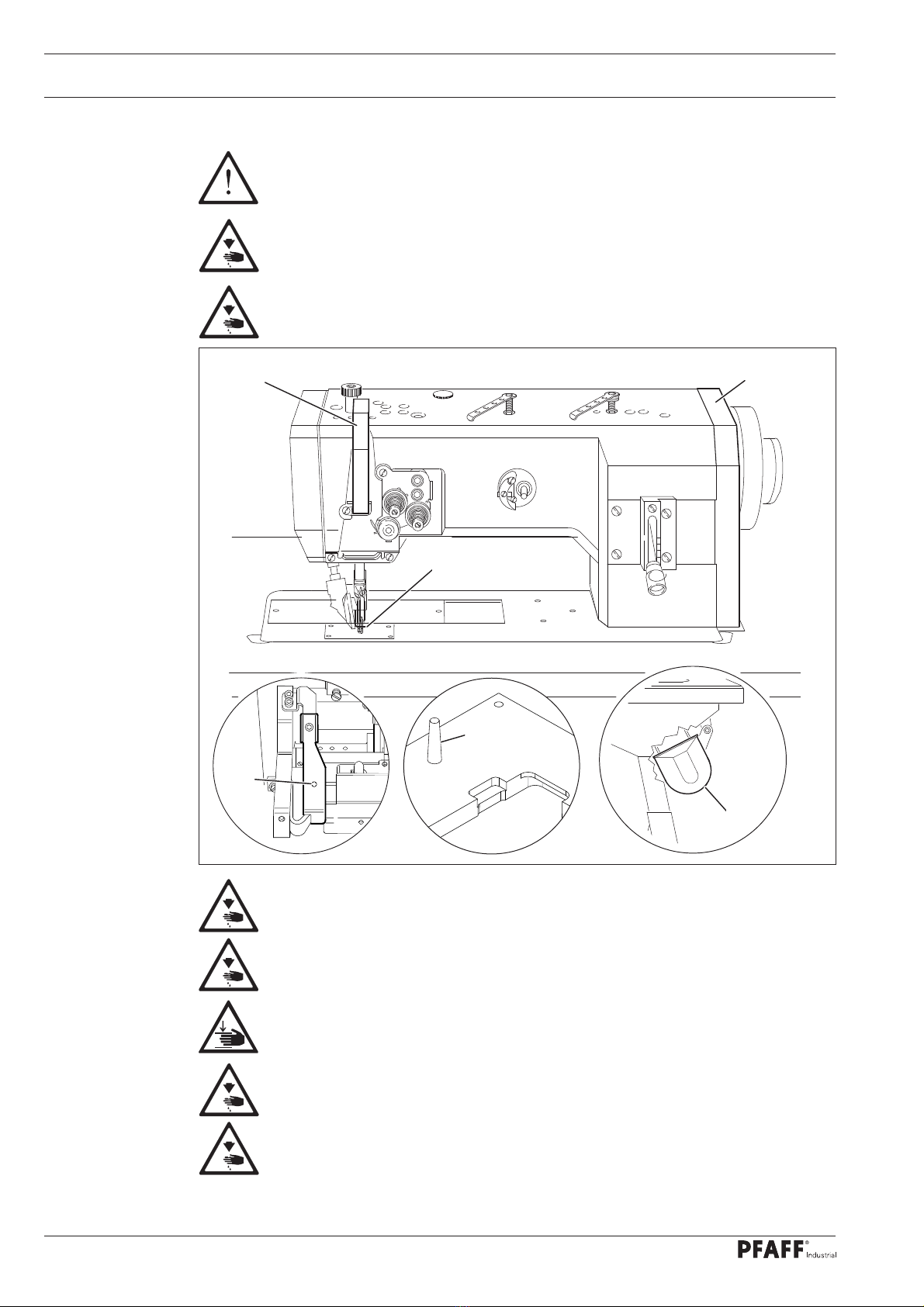

1.03 Safety symbols ...................................................................................................................... 6

1.04 Special points of attention for the owner-operator................................................................. 6

1.05 Operating personnel and technical staff ................................................................................ 7

1.05.01 Operating personnel .............................................................................................................. 7

1.05.02 Technical staff ........................................................................................................................ 7

1.06 Danger warnings.................................................................................................................... 8

2Proper Use............................................................................................................................ 9

3Technical Data.................................................................................................................... 10

3.01 PFAFF 1243.......................................................................................................................... 10

3.02 PFAFF 1244.......................................................................................................................... 11

4Disposal of the Machine.................................................................................................... 12

5Transport, Packaging and Storage ................................................................................... 13

5.01 Transport to the customer’s premises ................................................................................. 13

5.02 Transport within the customer’s premises........................................................................... 13

5.03 Disposal of the packaging materials .................................................................................... 13

5.04 Storage ................................................................................................................................ 13

6Work Symbols.................................................................................................................... 14

7Operating Controls ............................................................................................................15

7.01 Main switch ......................................................................................................................... 15

7.02 Buttons on the machine head (only in machines with backtacking system -911/..).............. 15

7.03 Treadle ................................................................................................................................. 16

7.04 Hand lever to raise the roller presser................................................................................... 16

7.05 Lever for stitch length regulation and reverse sewing ......................................................... 17

(In machines without backtacking system -911/..)................................................. 17

7.06 Lever for stitch length regulation (in machines with backtacking system -911/..).................. 17

7.07 Knee lever (in machines without backtacking system -911/..) .............................................. 18

7.08 Control panel (only in machines with P40 CD)..................................................................... 18

8Set-up and Initial Commissioning .................................................................................... 19

8.01 Set-up .................................................................................................................................. 19

8.01.01 Setting the table height........................................................................................................ 19

8.01.02 Inserting the sewing machine into the stand....................................................................... 20

8.01.04 Tensioning the V-belt ............................................................................................................ 21

8.01.06 Assembling the upper V-belt guard ...................................................................................... 22

8.01.07 Mounting the synchroniser .................................................................................................. 23

8.01.08 Assembling the anti-tipping device ......................................................................................23