Pfaff 469 User manual

Other Pfaff Sewing Machine manuals

Pfaff

Pfaff 3307-3 Series User manual

Pfaff

Pfaff 1171 User manual

Pfaff

Pfaff 571 User manual

Pfaff

Pfaff 337 Guide

Pfaff

Pfaff Creative Vision Technical manual

Pfaff

Pfaff creative 7560 User manual

Pfaff

Pfaff 3339 User manual

Pfaff

Pfaff Creative Vision User manual

Pfaff

Pfaff ClassicStyle 2025 User manual

Pfaff

Pfaff hobbymatic 917 User manual

Pfaff

Pfaff Coverstyle User manual

Pfaff

Pfaff 260C User manual

Pfaff

Pfaff 483 User manual

Pfaff

Pfaff hobby 350 User manual

Pfaff

Pfaff hobby 1022 User manual

Pfaff

Pfaff Creative 2134 User manual

Pfaff

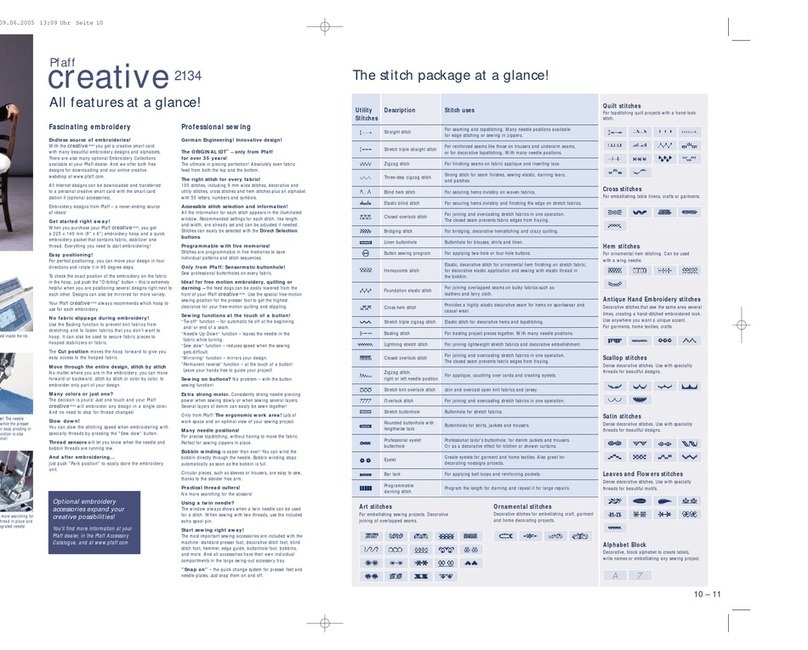

Pfaff Creative 2134 User manual

Pfaff

Pfaff hobbylock 795 User manual

Pfaff

Pfaff QUILT ARTIST II User manual

Pfaff

Pfaff 9083-2/99 User manual