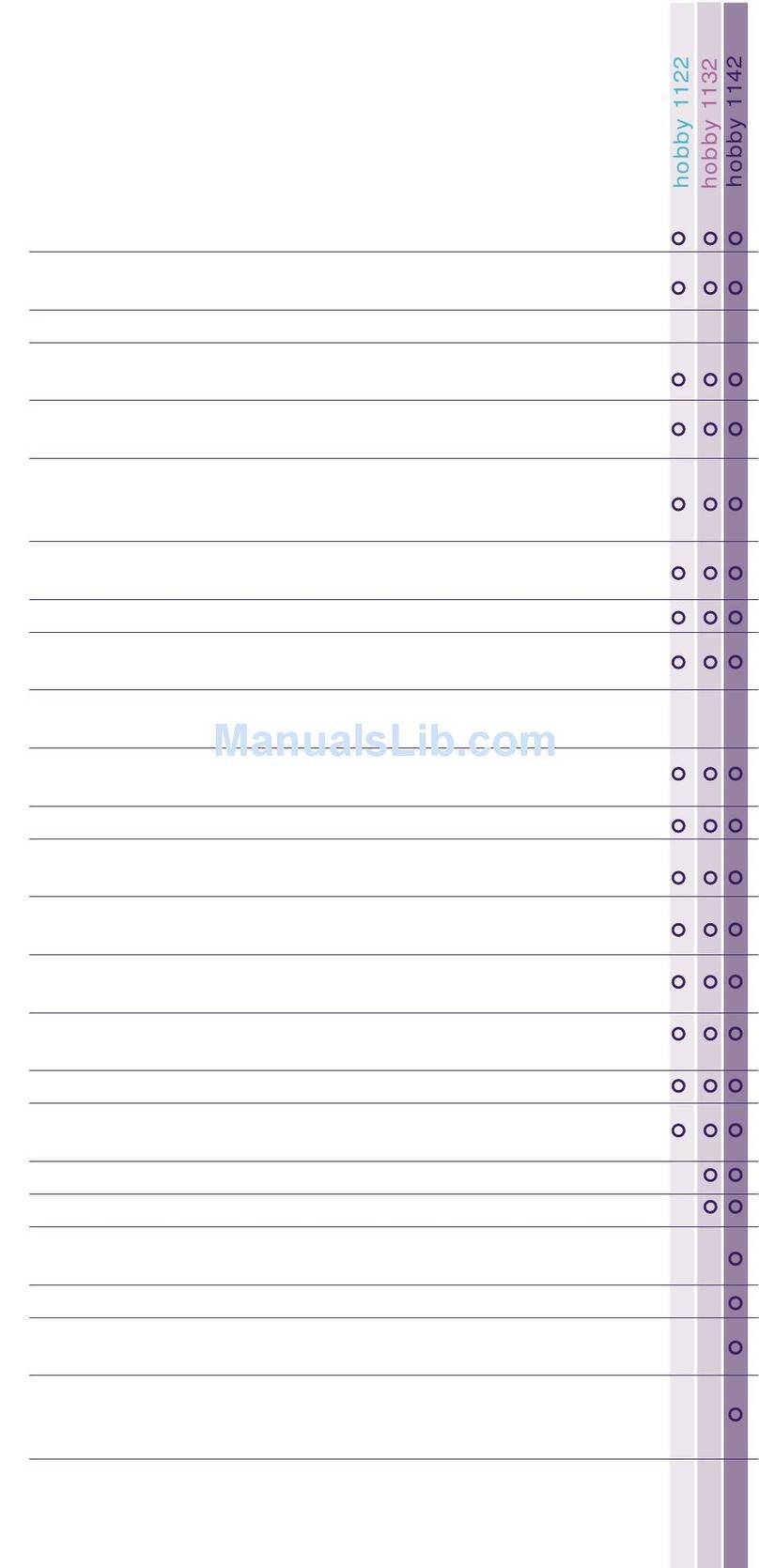

Contents

Contents ...............................................................................Chapter - Page

8Installation and initial operation ............................................................................. 8 - 1

8.01 Installation.................................................................................................................. 8 - 1

8.01.01 Adjusting the table-top height .................................................................................... 8 - 1

8.01.02 Adjusting the V-belt tension....................................................................................... 8 - 2

8.01.03 Fitting the upper V-belt guard .................................................................................... 8 - 2

8.01.04 Fitting the lower V-belt guard..................................................................................... 8 - 3

8.01.05 Fitting the tilt lock ...................................................................................................... 8 - 3

8.01.06 Fitting the synchronizer.............................................................................................. 8 - 4

8.01.07 Fitting the reel stand .................................................................................................. 8 -4

8.02 Commissioning .......................................................................................................... 8 - 5

8.03 Switching the machine on / off .................................................................................. 8 - 5

9Setting up ................................................................................................................. 9 - 1

9.01 Inserting the needle in the PFAFF 242 and PFAFF 1242 ........................................... 9 - 1

9.02 Inserting the needle in the PFAFF 1243..................................................................... 9 - 2

9.03 Inserting the needle in the PFAFF 244 and PFAFF 1244 ........................................... 9 - 2

9.04 Winding the bobbin thread, adjusting the thread tension .......................................... 9 - 3

9.05 Removing /inserting the bobbin case......................................................................... 9 - 4

9.06 Threading the bobbin case / adjusting the thread tension.......................................... 9 - 4

9.07 Threading the needle thread / adjusting the needle thread tension (PFAFF 1243)..... 9 - 5

9.08 Threading the needle thread / adjusting the needle thread tension

(PFAFF 242 and PFAFF .............................................................................................. 9 - 6

9.09 Threading the needle thread / adjusting the needle thread tension

(PFAFF 244 and PFAFF 1244 ..................................................................................... 9 - 7

10 Care and maintenance........................................................................................... 10 - 1

10.01 Servicing and maintenance intervals........................................................................ 10 - 1

10.02 Cleaning the hook compartment and the hook ........................................................ 10 - 1

10.03 General lubrication ................................................................................................... 10 - 2

10.04 Lubricating the hook ................................................................................................ 10 - 3

10.05 Lubricating the needle head parts............................................................................ 10 - 4

10.06 Checking / adjusting the air pressure ....................................................................... 10 - 4

10.07 Emptying / cleaning the water container of the air filter .......................................... 10 - 5

11 Adjustment ............................................................................................................. 11 - 1

11.01 Notes on adjusting ................................................................................................... 11 - 1

11.02 Tools, gauges and other accessories ....................................................................... 11 - 1

11.03 Abbreviations ........................................................................................................... 11 - 1

11.04 Adjusting the basic machine................................................................................. 11 - 2

11.04.01 Positioning the feed dog .......................................................................................... 11 - 2

11.04.02 Height of the feed dog............................................................................................. 11 - 3

11.04.03 Pre-adjusting the needle height ............................................................................... 11 - 4

11.04.04 Centering the needle in the needle hole (PFAFF 242 and 1242 ............................... 11 - 5

11.04.05 Centering the needle in the needle hole (PFAFF 244, 1243 and 1244) .................... 11 - 6

11.04.06 Driving motion of the feed dog (PFAFF 242 and 1242) ............................................ 11 - 7