Index

Contents ..................................................................................Page

3

1Safety .................................................................................................................................... 5

1.01 Directives...............................................................................................................................5

1.02 General notes on safety......................................................................................................... 5

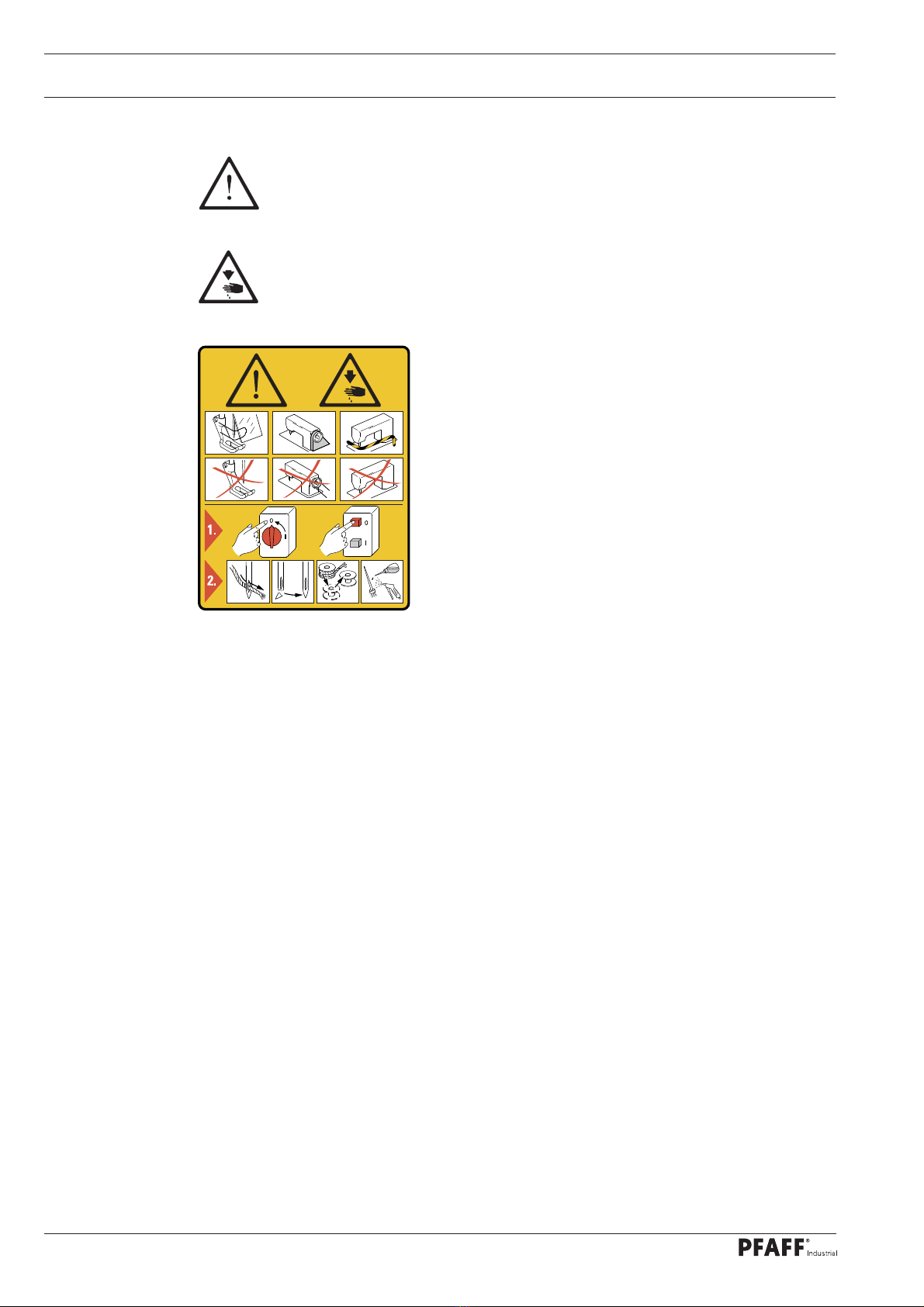

1.03 Safety symbols ...................................................................................................................... 6

1.04 Important points for the user................................................................................................. 6

1.05 Operating and specialist personnel........................................................................................ 7

1.05.01 Operating personnel .............................................................................................................. 7

1.05.02 Specialist personnel............................................................................................................... 7

1.06 Danger warnings.................................................................................................................... 8

2Proper use............................................................................................................................. 9

3Specifications ..................................................................................................................... 10

3.01 PFAFF 1181, PFAFF 1183 .....................................................................................................10

3.02 Versions and subclasses ...................................................................................................... 11

4Disposal of Machine .......................................................................................................... 12

5Transportation, packing and storage................................................................................ 13

5.01 Transportation to customer‘s premises ............................................................................... 13

5.02 Transportation inside the customer‘s premises................................................................... 13

5.03 Disposal of packing materials ..............................................................................................13

5.04 Storage ................................................................................................................................ 13

6Explanation of symbols..................................................................................................... 14

7Controls .............................................................................................................................. 15

7.01 On/off switch ....................................................................................................................... 15

7.02 Keys on the machine head (only for machines with -911/..) ................................................. 15

7.03 Pedal .................................................................................................................................... 16

7.04 Lever for lifting the presser foot........................................................................................... 16

7.05 Feed regulator disk / Reverse feed lever.............................................................................. 17

7.06 Knee lever ............................................................................................................................ 17

7.07 Edge trimmer -731/01 .......................................................................................................... 18

7.08 Control panel........................................................................................................................ 18

8Installation and commissioning ....................................................................................... 19

8.01 Installation............................................................................................................................ 19

8.01.01 Adjusting the table-top height.............................................................................................. 19

8.01.02 Adjusting the V-belt tension ................................................................................................. 20

8.01.03 Mounting the upper V-belt guard .........................................................................................20

8.01.04 Mounting the lower V-belt guard.......................................................................................... 21

8.01.05 Mounting the spool holder .................................................................................................. 21

8.02 Connecting the plug-in connections and earth cables ......................................................... 22

8.03 Commissioning the machine .............................................................................................. 23