Contents

Contents .................................................................................Chapter – Page

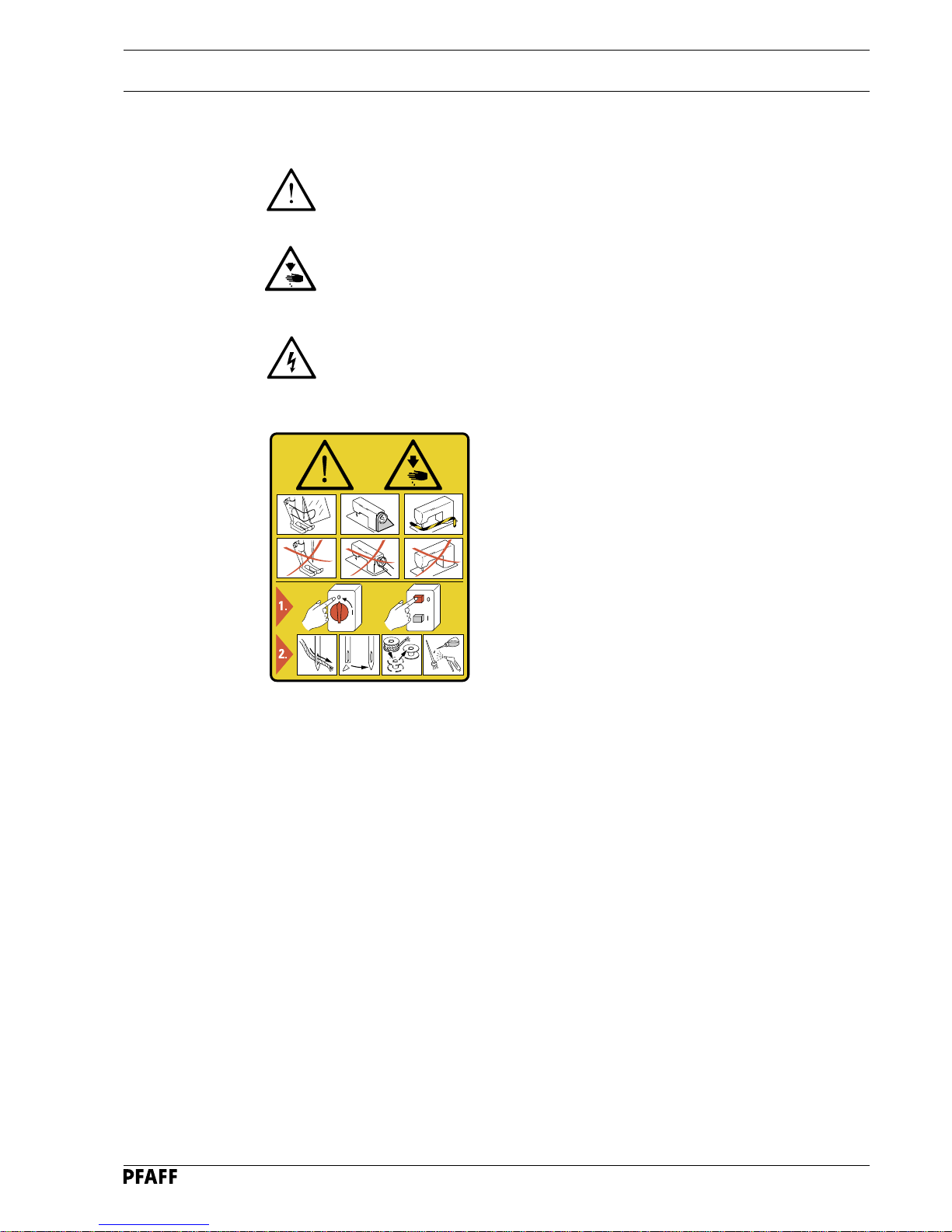

1Safety ........................................................................................................................... 1 - 1

1.01 Regulations ................................................................................................................... 1 - 1

1.02 General notes on safety ................................................................................................ 1 - 1

1.03 Safety symbols ............................................................................................................. 1 -2

1.04 Important notes for the user ......................................................................................... 1 - 2

1.05 Notes for operating and technical staff ......................................................................... 1 - 3

1.05.01 Operating staff .............................................................................................................. 1 - 3

1.05.02 Technical staff............................................................................................................... 1 - 3

1.06 Danger warnings........................................................................................................... 1 - 4

2Proper Use ................................................................................................................... 2 - 1

3Specifications .............................................................................................................. 3 - 1

3.01 General information....................................................................................................... 3 - 1

3.02 Stitch formations of the various sub-classes................................................................. 3 - 2

4Disposal of Machine ................................................................................................... 4 - 1

5Transportation, packing and storage......................................................................... 5 - 1

5.01 Transportation to customer’s premises ........................................................................ 5 - 1

5.02 Transportation inside customer’s premises .................................................................. 5 - 1

5.03 Disposal of packing materials........................................................................................ 5 - 1

5.04 Storage ......................................................................................................................... 5 - 1

6Explanation of symbols .............................................................................................. 6 - 1

7Controls ....................................................................................................................... 7- 1

7.01 On/off switch ................................................................................................................7- 1

7.02 Pedal ............................................................................................................................. 7 - 1

7.03 Preventing knife engagement ....................................................................................... 7 - 2

7.04 Control panel................................................................................................................. 7 - 3

8Installation and commissioning ................................................................................. 8 - 1

8.01 Installation..................................................................................................................... 8 - 1

8.01.01 Adjusting the table height ............................................................................................. 8 - 1

8.01.02 Installation variants ....................................................................................................... 8 - 2

8.01.03 Connecting the plug-type connections .......................................................................... 8 - 3

8.01.04 Fitting the reel stand ..................................................................................................... 8 - 4

8.02 Commissioning ............................................................................................................. 8 - 4

8.03 Switching the machine on / off ..................................................................................... 8 - 4

8.04 Setting up the machine control unit .............................................................................. 8 - 5

8.04.01 Establishing the sub-class ............................................................................................. 8 - 5

8.04.02 Setting parameter "202" ................................................................................................ 8 - 6

9Setting up .................................................................................................................... 9 -1

9.01 Inserting the needle ...................................................................................................... 9 - 1

9.02 Winding the bobbin thread / adjusting the preliminary thread tension........................... 9 - 2

9.03 Threading the bobbin case / adjusting the thread tension ............................................. 9 - 3

9.04 Changing the bobbin ..................................................................................................... 9 - 4

9.05 Threading the needle thread ......................................................................................... 9 - 5