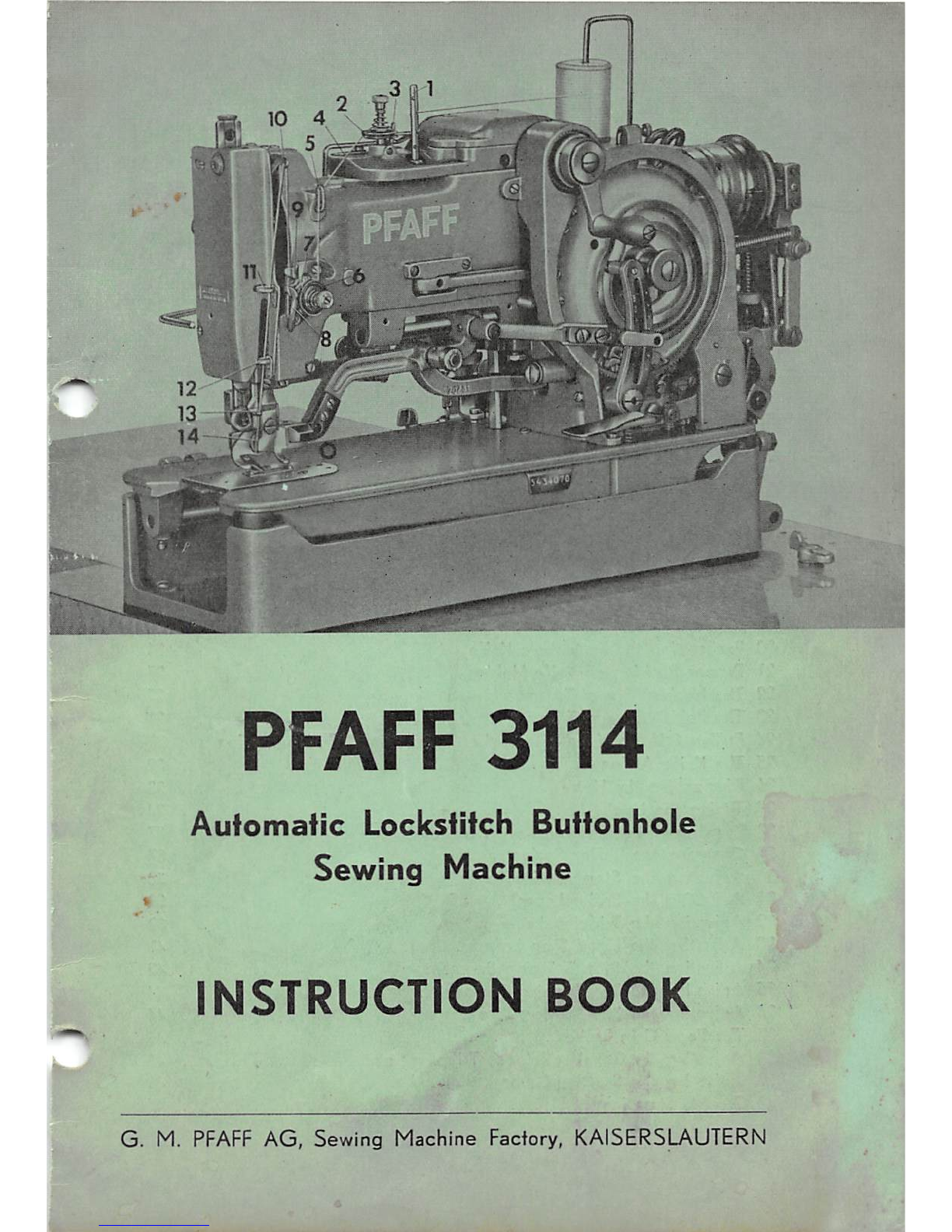

Pfaff 3114 User manual

Other Pfaff Sewing Machine manuals

Pfaff

Pfaff 3822-1/32 User manual

Pfaff

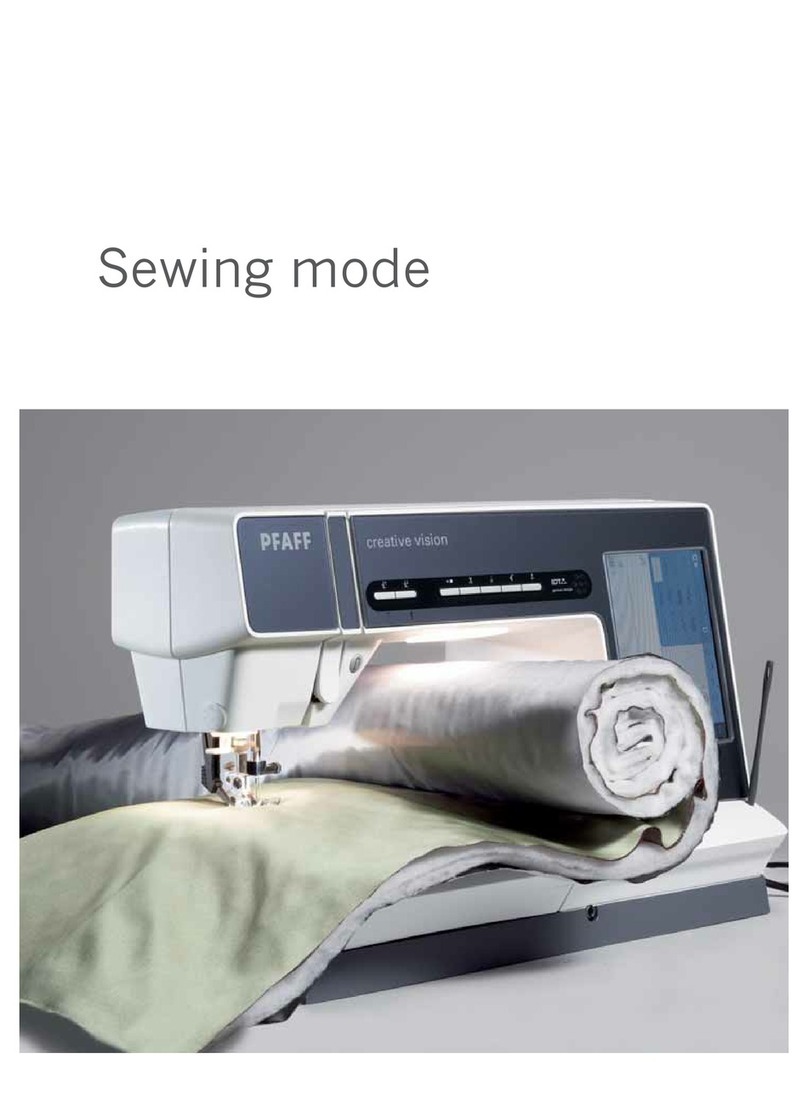

Pfaff Creative Vision User manual

Pfaff

Pfaff Creative Vision Manual

Pfaff

Pfaff 1196 User manual

Pfaff

Pfaff hobby 1122 Guide

Pfaff

Pfaff 1591 User manual

Pfaff

Pfaff 1029 User manual

Pfaff

Pfaff ClassicStyle 1525 User manual

Pfaff

Pfaff 212 User manual

Pfaff

Pfaff Creative Vision User manual

Pfaff

Pfaff 918 User manual

Pfaff

Pfaff creative 1469 User manual

Pfaff

Pfaff 333-712/02 User manual

Pfaff

Pfaff expression 150 User manual

Pfaff

Pfaff hobbyblock 794 User manual

Pfaff

Pfaff Powerline 2545 Guide

Pfaff

Pfaff varimatic 6085 User manual

Pfaff

Pfaff select 150 User manual

Pfaff

Pfaff hobbymatic 904-1 User manual

Pfaff

Pfaff 337 Guide