Index

Contents ..................................................................................Page

1Safety .................................................................................................................................... 5

1.01 Regulations ............................................................................................................................ 5

1.02 General notes on safety......................................................................................................... 5

1.03 Safety symbols ...................................................................................................................... 6

1.04 Important notes for the user.................................................................................................. 6

1.05 Notes for operating and technical staff .................................................................................. 7

1.05.01 Operating staff ....................................................................................................................... 7

1.05.02 Technical staff ........................................................................................................................ 7

1.06 Danger warnings.................................................................................................................... 8

2Proper use............................................................................................................................. 9

3Specifications ..................................................................................................................... 10

3.01 PFAFF 5489.......................................................................................................................... 10

3.02 Models and work aids ......................................................................................................... 10

4Disposal of Machine ...........................................................................................................11

5Transportation, packing and storage................................................................................ 12

5.01 Transportation to customer‘s premises ............................................................................... 12

5.02 Transportation inside the customer‘s premises................................................................... 12

5.03 Disposal of packing materials ..............................................................................................12

5.04 Storage ................................................................................................................................ 12

6Explanation of symbols..................................................................................................... 13

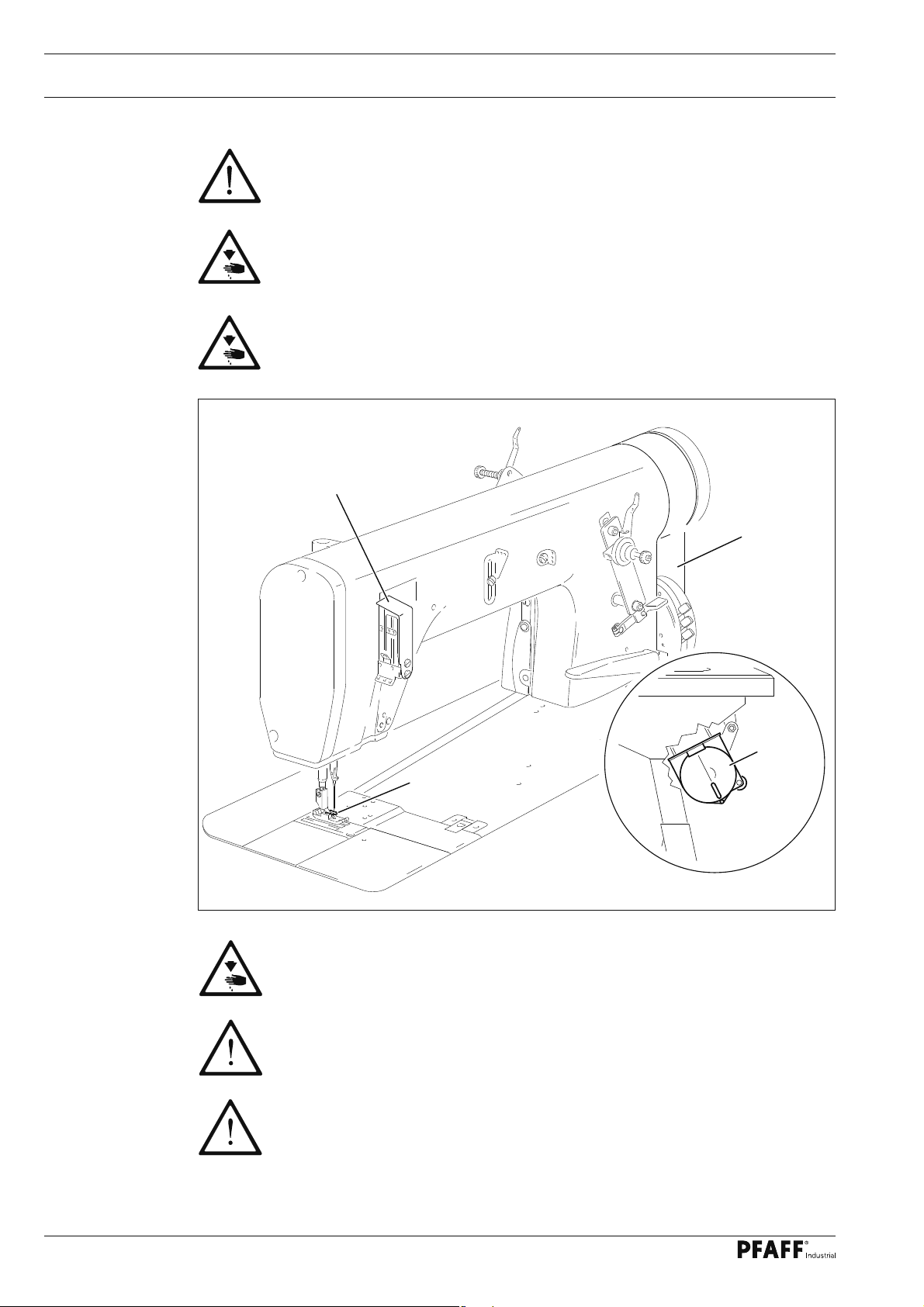

7Controls .............................................................................................................................. 14

7.01 Main switch ......................................................................................................................... 14

7.02 Pedal .................................................................................................................................... 14

7.03 Keys on the machine head................................................................................................... 15

7.04 Raising the presser foot....................................................................................................... 15

7.05 Thread tension release lever................................................................................................ 16

7.06 Reverse feed lever ............................................................................................................... 16

7.07 Stitch length and Differential feed levers ............................................................................. 17

7.08 Control panel........................................................................................................................ 17

7.09 Puller (-948/26)..................................................................................................................... 17

8Installation and commissioning ....................................................................................... 18

8.01 Installation............................................................................................................................ 18

8.01.01 Adjusting the table-top height.............................................................................................. 18

8.01.02 Assembling the motor P40 ED ............................................................................................ 19

8.01.03 Tightening the V-belt ............................................................................................................ 19

8.01.04 Mounting the bottom V-belt guard ....................................................................................... 20