Index

Contents ..................................................................................Page

13 Adjustment ........................................................................................................................... 5

13.01 Notes on adjustment ............................................................................................................. 5

13.02 Tools, gauges and other accessories for adjusting ............................................................... 5

13.03 Abbreviations ......................................................................................................................... 5

13.04 Explanation of the symbols.................................................................................................... 5

13.01 Adjusting the basic machine .................................................................................................. 6

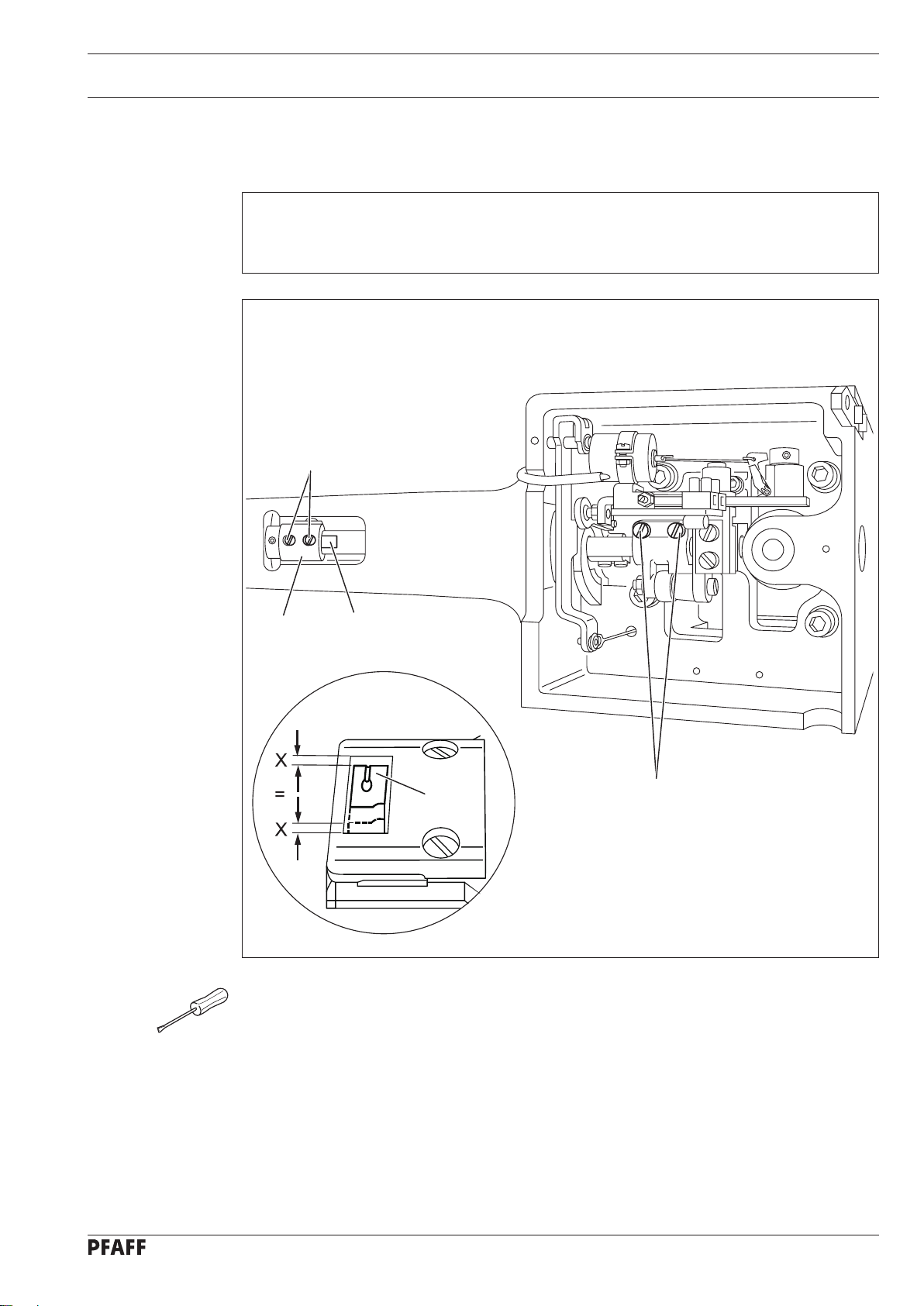

13.04.01 Lateral positioning of the feed dog ........................................................................................ 6

13.04.02 Lengthwise positioning of the feed dog ................................................................................ 7

13.04.03 Height of the bottom feed dog (only on machines with lifting phase – P-version)................. 8

13.04.04 Centering the needle in the needle hole................................................................................ 9

13.04.05 Pre-adjusting the needle height ........................................................................................... 10

13.04.06 Driving motion of the top and bottom feed dogs................................................................. 11

13.04.07 Lifting motion of the bottom feed dog (only on machines with lifting phase – P-version).... 12

13.04.08 Needle rise, hook-to-needle clearance and needle height ................................................... 13

13.04.09 Vibrating presser lift ............................................................................................................. 14

13.04.10 Vibrating presser feeding motion......................................................................................... 15

13.04.11 Needle thread tension release............................................................................................. 16

13.04.12 Thread check spring ............................................................................................................. 17

13.04.13 Bobbin winder...................................................................................................................... 18

13.04.14 Regulating the pressure on the presser foot ....................................................................... 19

13.05 Adjusting the thread trimmer -900/52.................................................................................. 20

13.05.01 Preadjusting the control cam ............................................................................................... 20

13.05.02 Tripping lever height............................................................................................................. 21

13.05.03 Control pin ........................................................................................................................... 22

13.05.04 Engaging solenoid................................................................................................................ 23

13.05.05 Control pin height ................................................................................................................ 24

13.05.06 Front position of thread catcher ........................................................................................... 25

13.05.07 Lateral position of thread catcher ........................................................................................ 26

13.05.08 Control cam (final adjustment)............................................................................................. 27

13.05.09 Knife..................................................................................................................................... 28

13.05.10 Needle thread tension release............................................................................................. 29

13.05.11 Cutting test................................................................................................................................30