Table of Contents

Contents ..................................................................................Page

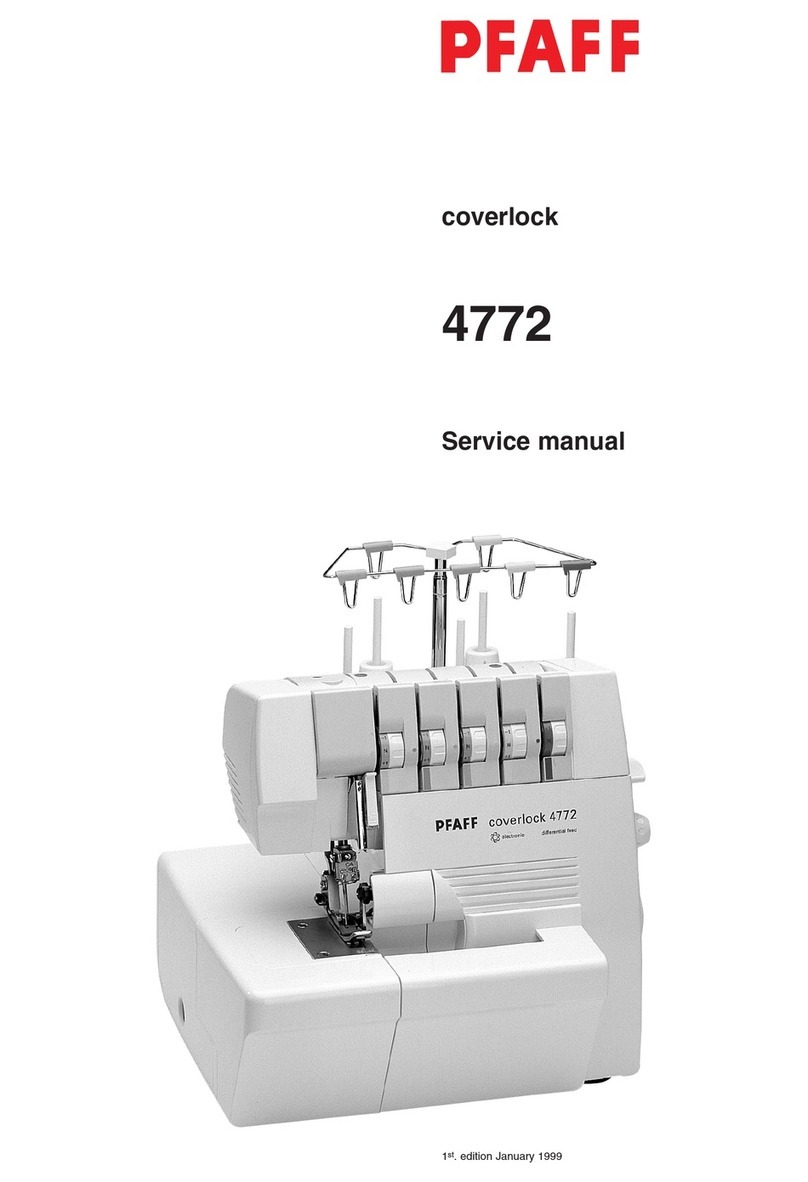

13 Adjustment ........................................................................................................................... 5

13.01 Tools, gauges and other accessories .................................................................................... 5

13.02 Abbreviations ......................................................................................................................... 5

13.03 Explanation of symbols.......................................................................................................... 5

13.04 Adjusting basic machine ........................................................................................................ 6

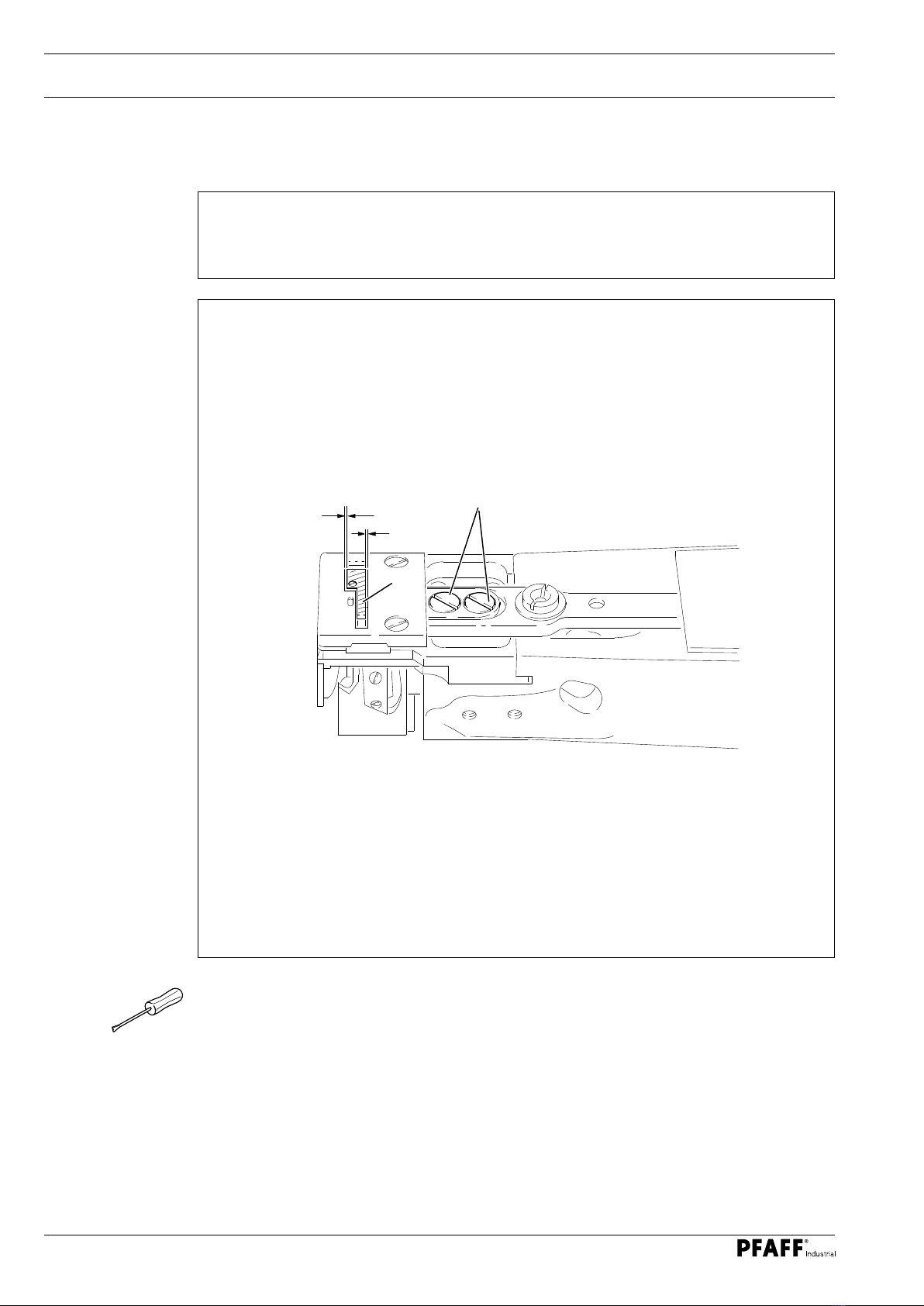

13.04.01 Feed dog position crossways to sewing direction................................................................. 6

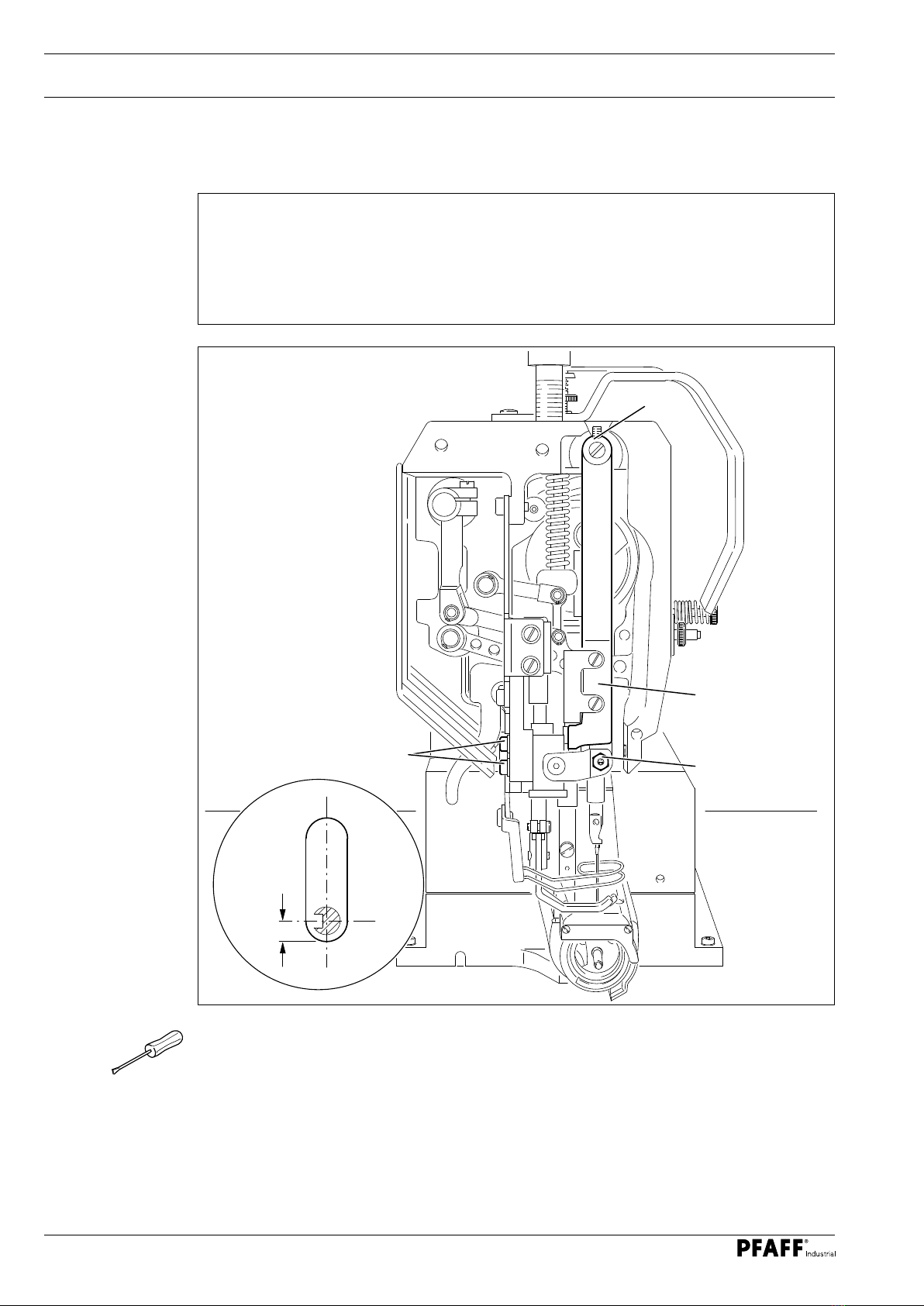

13.04.02 Feed dog position in sewing direction ................................................................................... 7

13.04.03 Needle position to needle hole .............................................................................................. 8

13.04.04 Needle height (pre-calibrating) ............................................................................................... 9

13.04.05 Bottom and top feed sliding movement .............................................................................. 10

13.04.06 Hook-to-needle clearance, needle bar rise, needle height and needle guard ...................... 11

13.04.07 Top feed lift.......................................................................................................................... 12

13.04.08 Top feed stroke movement ................................................................................................. 13

13.04.09 Top feed pendulum.............................................................................................................. 14

13.04.10 Needle thread tension release............................................................................................. 15

13.04.11 Thread check spring............................................................................................................. 16

13.04.12 Bobbin winder...................................................................................................................... 17

13.04.13 Presser foot pressure .......................................................................................................... 18

13.05 Adjusting thread trimmer -900/51 .................................................................................... 19

13.05.01 Control cam ( pre-calibrating ) .............................................................................................. 19

13.05.02 Tripping lever height ............................................................................................................ 20

13.05.03 Feed regulator pin................................................................................................................ 21

13.05.04 Engaging solenoid................................................................................................................ 22