Index

Contents ..................................................................................Page

1Adjustment ........................................................................................................................... 5

1.01 Tools, gauges and other accessories for adjusting ................................................................ 5

1.02 Abbreviations ......................................................................................................................... 5

1.03 Explanation of the symbols.................................................................................................... 5

1.04 Check and adjustment aid...................................................................................................... 6

1.05 Adjusting the basic machine .................................................................................................. 7

1.05.01 Balancing weight.................................................................................................................... 7

1.05.02 Centering the needle in the needle hole (in sewing direction)............................................... 8

1.05.03 Parallel guiding of the needle bar........................................................................................... 9

1.05.04 Locking lever ........................................................................................................................ 10

1.05.05 Zero stitch and zigzag stitch scale........................................................................................ 11

1.05.06 Centering the needle in the needle hole (crosswise to sewing direction)........................... 12

1.05.07 Zigzag stitch width ............................................................................................................... 13

1.05.08 Multi-stitch movement (only on the PFAFF 939U) ............................................................... 14

1.05.09 Zigzag stitch movement (only on the PFAFF 3704-2/..)........................................................ 15

1.05.10 Needle penetration symmetry - left, centre and right (only on the PFAFF 3704-2/..)........... 16

1.05.11 Zigzag movement (only on the 939U) .................................................................................. 17

1.05.12 Target positioning sensor (only on the 939U) ...................................................................... 18

1.05.13 Needle position adjustment lever ........................................................................................19

1.05.14 Adjustment wheels for differential feed (only on the PFAFF 939U) ..................................... 20

1.05.15 Zeroing the differentiatio (only on the PFAFF 939 U) ........................................................... 21

1.05.16 Differential feed synchronisation (only on the PFAFF 3704-2/..)........................................... 22

1.05.17 Position of the stitch length adjustment wheel (on the PFAFF 939 U) ................................ 23

1.05.18 Position of the stitch length adjustment wheel (on the PFAFF 3704-2/..)............................ 24

1.05.19 Zeroing the main feed (rear feed dog) on the PFAFF 939 U................................................. 25

1.05.20 Zeroing the main feed (rear feed dog) on the PFAFF 3704-2/.. ............................................ 26

1.05.21 Zeroing the differential feed (front feed dog) on the PFAFF 939 U ...................................... 27

1.05.22 Zeroing the differential feed (front feed dog) on the PFAFF 3704-2/.................................... 28

1.05.23 Torsion spring of the reverse feed lever (on the PFAFF 939 U)............................................ 29

1.05.24 Torsion spring of the reverse feed lever (on the PFAFF 3704-2/..) ....................................... 30

1.05.25 Torsion spring of the differentiation regulating shaft (on the PFAFF 939 U)......................... 31

1.05.26 Torsion spring of the differentiation regulating shaft (on the PFAFF 3704-2/..) .................... 32

1.05.27 Feeding motion of the main and differential feeds .............................................................. 33

1.05.28 Lifting stroke of the main and differential feed dogs............................................................ 34

1.05.29 Height of the main and differential feed dogs...................................................................... 35

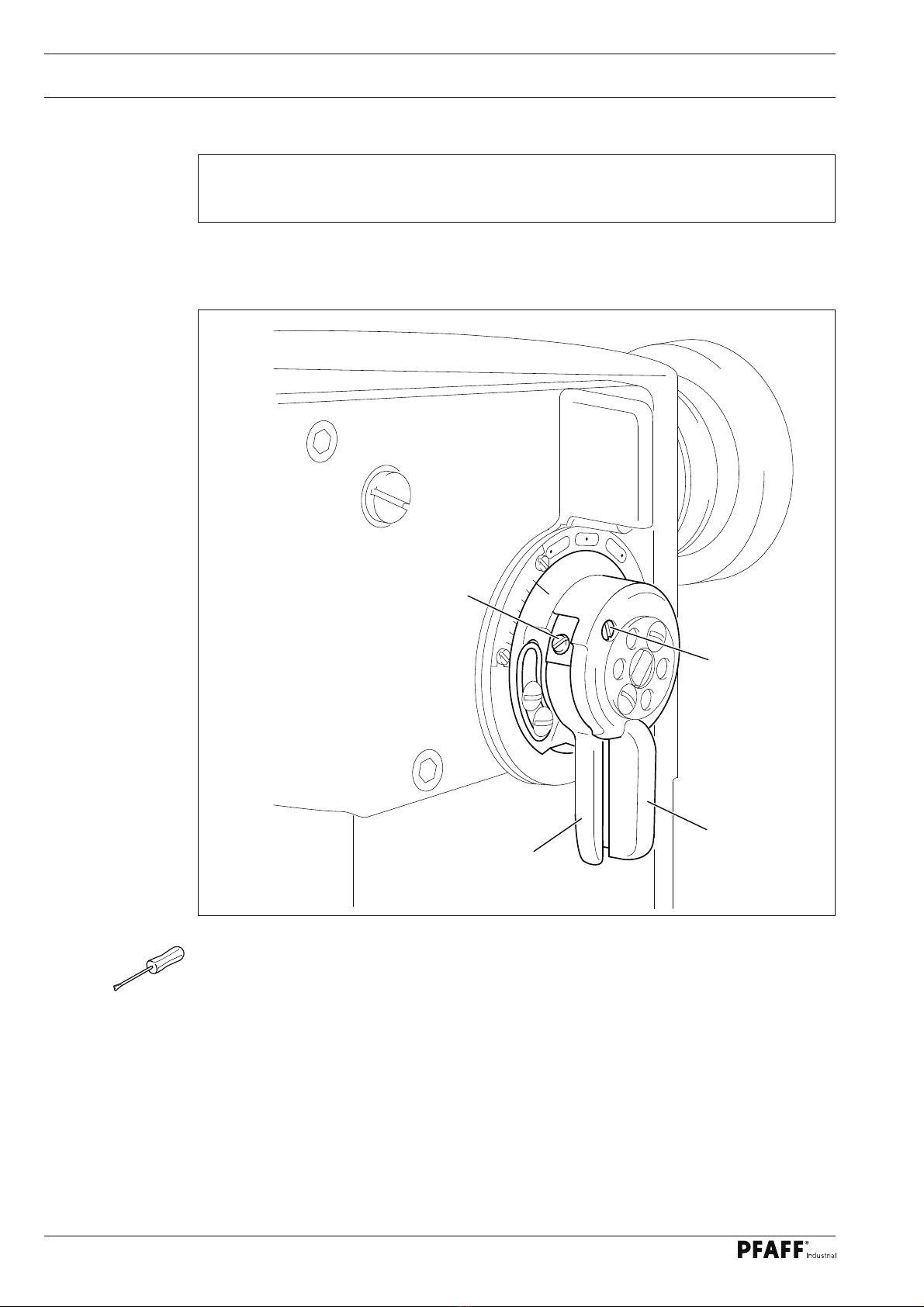

1.05.30 Drive belt in the gearbox housing ........................................................................................ 36

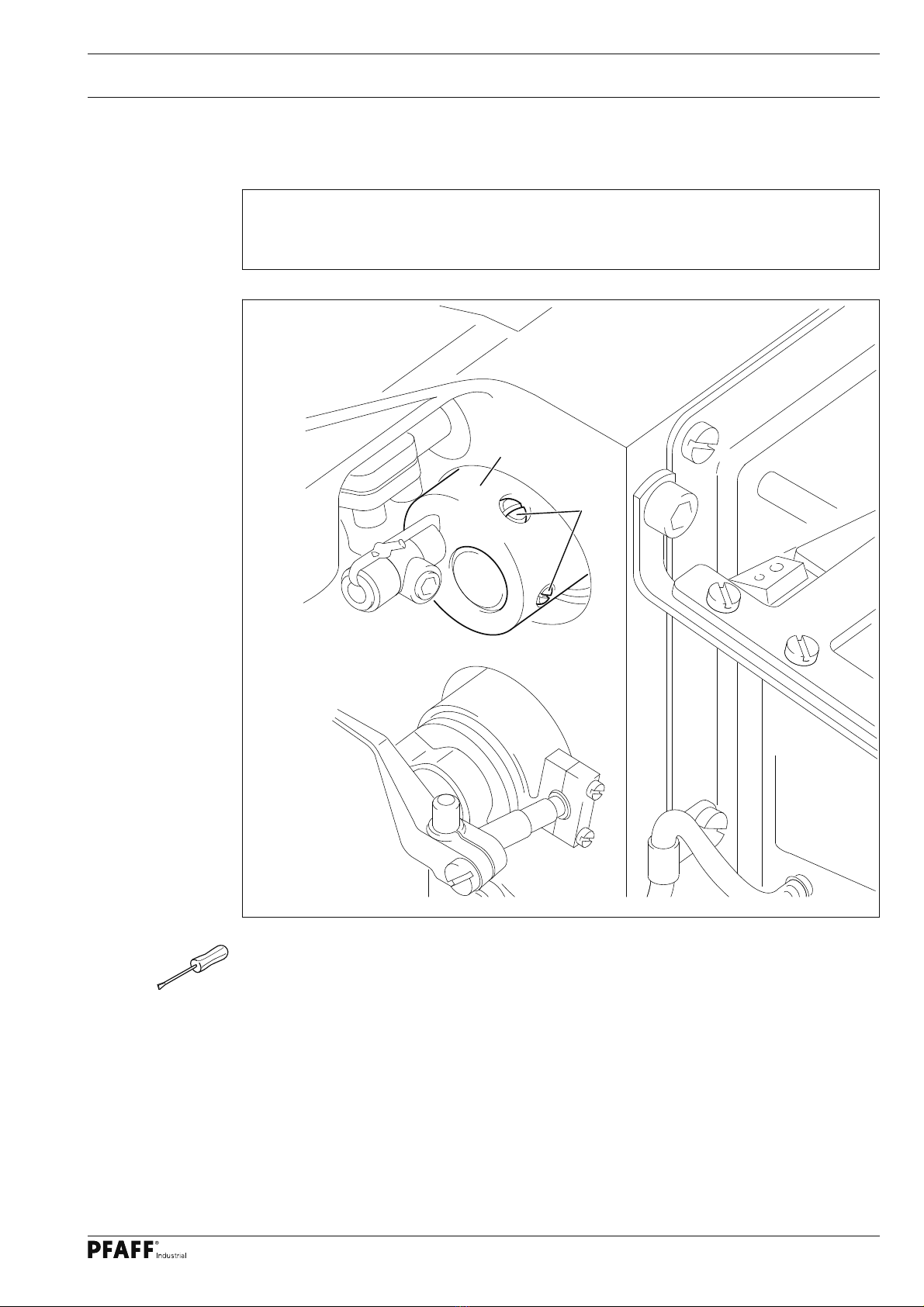

1.05.31 Hook bearing bracket .......................................................................................................... 37