2.3 Safety precautions

Duty to provide information on potential dangers

The product holder or user is obliged to make all operating personnel aware of dangers

posed by this product.

Every person who is involved in the installation, operation or maintenance of the product

must read, understand and adhere to the safety-related parts of this document.

Infringement of conformity due to modifications to the product

The Declaration of Conformity from the manufacturer is no longer valid if the operator

changes the original product or installs additional equipment.

●Following the installation into a system, the operator is required to check and re-evalu-

ate the conformity of the overall system in the context of the relevant European Direc-

tives, before commissioning that system.

General safety precautions when handling the product

►Observe all applicable safety and accident prevention regulations.

►Check that all safety measures are observed at regular intervals.

►Recommendation: Establish a secure connection to the earthed conductor (PE); protection class I.

►Never disconnect plug connections during operation.

►Keep lines and cables away from hot surfaces (> 70 °C).

►Do not carry out your own conversions or modifications on the unit.

►Observe the unit protection category prior to installation or operation in other environments.

2.4 Product usage limits

Parameter Air cooling

Permissible ambient temperature with heating max. +35 °C1)

Ambient temperature max. +12 °C to +40 °C

Protection degree IP20

Relative air humidity ≤ 85 % not condensing

Tbl. 4: Permissible ambient and operating conditions

2.5 Proper use

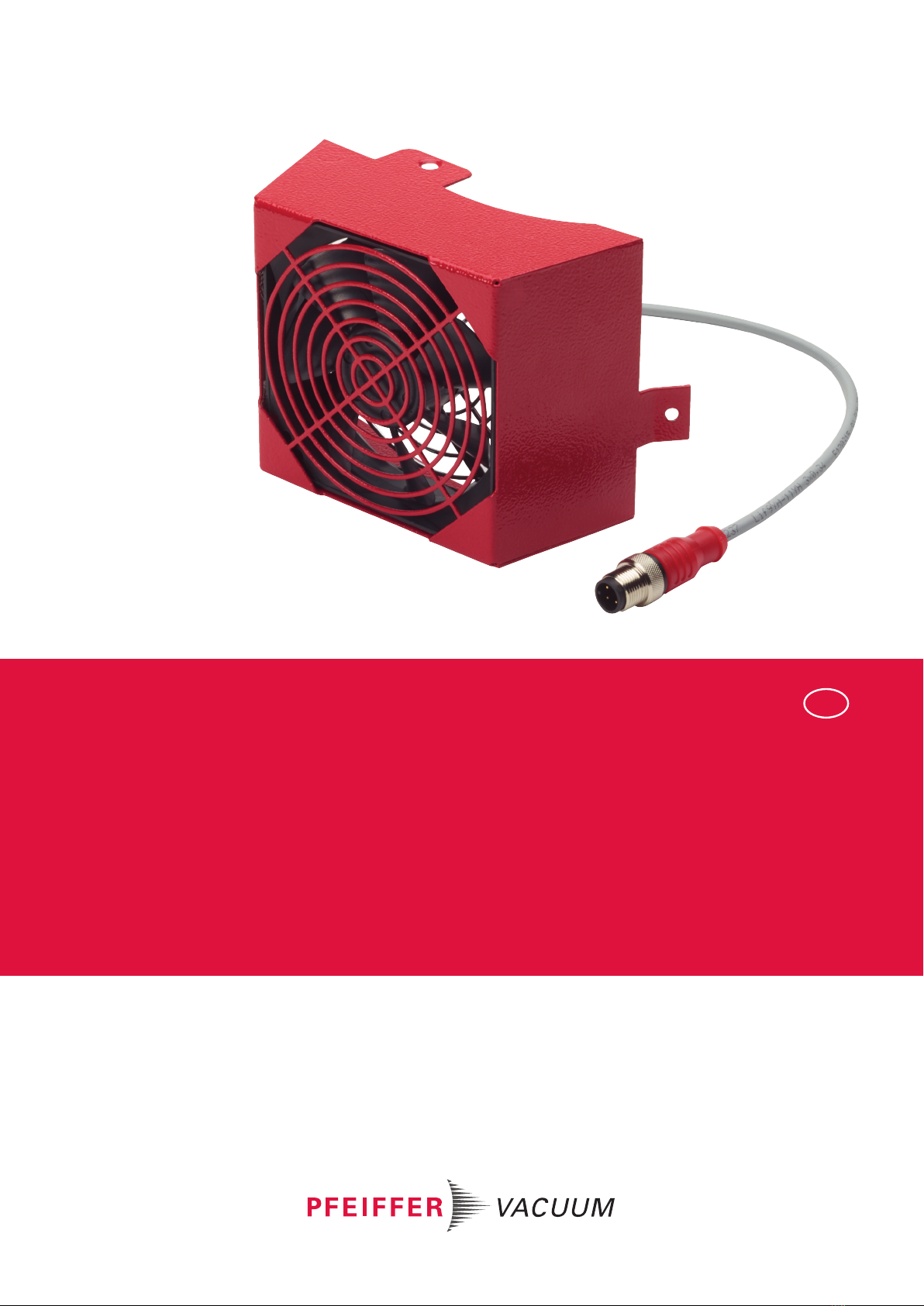

►Use the air cooling exclusively for the cooling of Pfeiffer Vacuum turbopumps in ambient tempera-

tures up to a max. 35 °C.

►Adhere to the installation, commissioning, operating, and maintenance instructions.

►Do not use any accessory parts other than those recommended by Pfeiffer Vacuum.

►Always use air cooling rather than water cooling for processes with a lower gas throughput and

good fore-vacuum pressure.

2.6 Foreseeable misuse

Improper use of the product invalidates all warranty and liability claims. Any use that is counter to the

purpose of the product, whether intentional or unintentional, is regarded as improper use, in particular:

●Connection to pumps or equipment which are not suitable for this purpose according to their oper-

ating instructions

●Connection to equipment with exposed live parts

1) Water cooling is required for higher temperatures

Safety

9/26