Revision 3 | Operating instructions sample cleaner MLN

1 Introduction..................................................................................................................................5

1.1 Intended use............................................................................................................................... 5

1.2 Declaration of conformity .......................................................................................................... 6

1.3 Structural features of the danger notes..................................................................................... 7

1.4 Pictograms in the operating instructions ................................................................................... 7

1.5 Identification .............................................................................................................................. 8

2 Safety ...........................................................................................................................................8

2.1 Installed safety systems ............................................................................................................. 8

2.1.1 Supply isolating device (plug/socket combination)....................................................... 8

2.1.2 System control............................................................................................................... 9

2.1.3 Limit switch system ....................................................................................................... 9

2.1.4 Protective caps .............................................................................................................. 9

2.2 Interfaces at sample cleaner MLN............................................................................................ 10

2.3 Operating and hazard areas associated with the machine ...................................................... 10

2.4 Operating and maintenance personnel ................................................................................... 11

2.5 Safety measures (to be implemented by the operating company) ......................................... 11

2.6 General safety instructions ...................................................................................................... 12

2.7 Safety tests ............................................................................................................................... 13

2.8 Residual hazards associated with the sample cleaner ............................................................. 13

2.9 Deactivation procedure............................................................................................................ 13

3 Technical data.............................................................................................................................14

3.1 Dimensions and weight ............................................................................................................ 14

3.2 Power supply ............................................................................................................................ 14

3.3 General information................................................................................................................. 14

4 Delivery, transport and storage...................................................................................................14

4.1 Scope of delivery ...................................................................................................................... 14

4.2 Transport and packaging .......................................................................................................... 15

4.3 Temporary storage ................................................................................................................... 15

4.4 Transport to installation location (of customer) ...................................................................... 15

5 Installation and commissioning...................................................................................................17

5.1 Positioning of sample cleaner MLN.......................................................................................... 17

6 Function......................................................................................................................................18

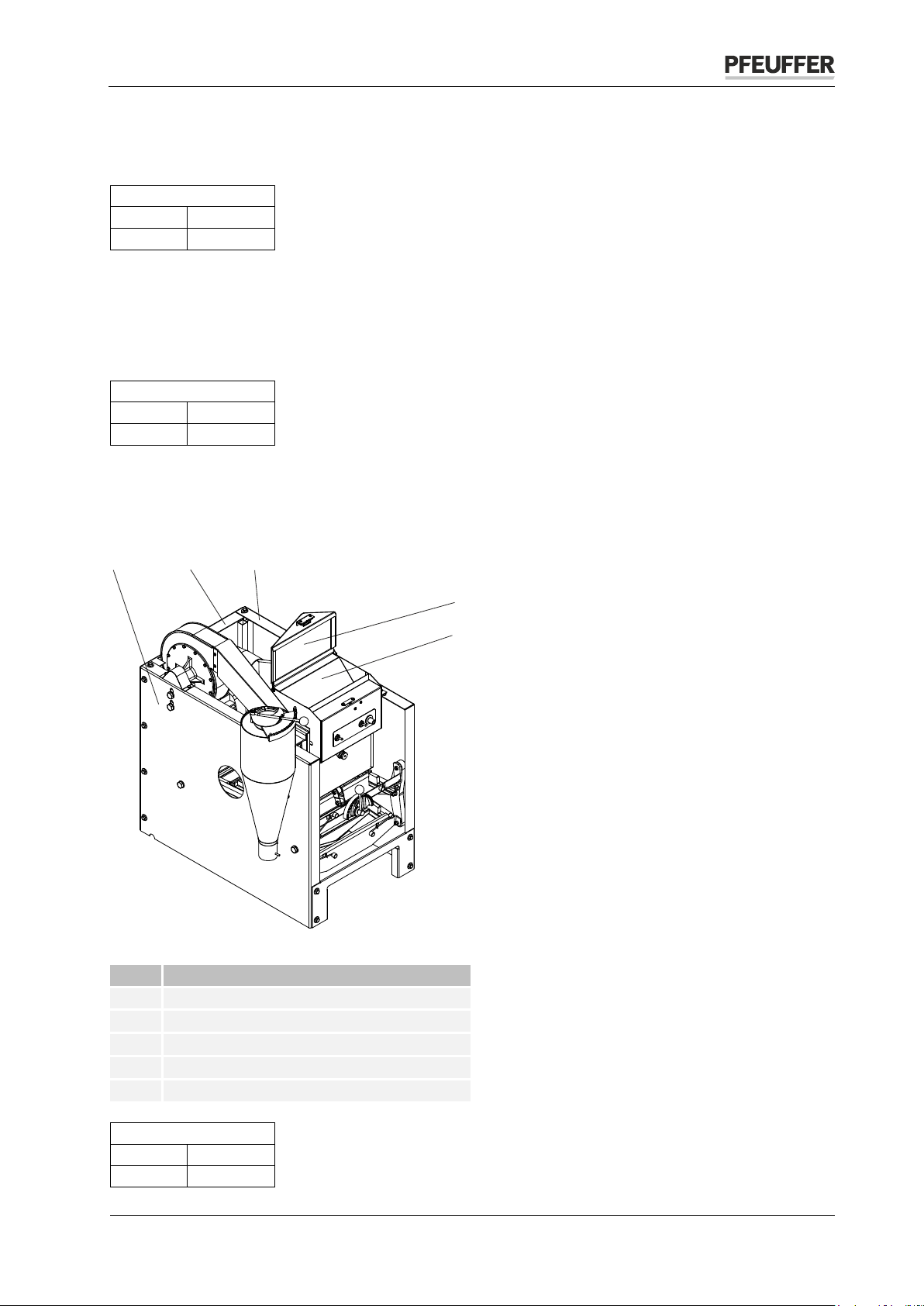

6.1 Components of sample cleaner MLN ....................................................................................... 18

6.2 Functional sequence ................................................................................................................ 19

7 Operation ...................................................................................................................................20