DINKO Instruments UV/VIS 6000 User manual

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

1

UV/VIS 6000 Ultraviolet Visible Spectrophotometer

Smart Touch Screen

Reference Manual

Version: March 2021

Mark

c/ Encarnació, 123-125 / 08024-Barcelona

dinter@dinko.es www.dinko.es

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

2

Dear user:

Thank you for purchasing and using the instrument of shanghai metash

instrument corporation. Please read the manual carefully to enable you to

know the performance of the instrument as soon as possible and to master

its using method.

The copyright of the manual belongs to shanghai metash instrument

corporation. Without the permission of our company, deleting and copying

of the contents in any form is forbad for anybody.

It is possible to modify the contents of the manual for the need of improving.

If any modification happens, please forgive us no further notice.

You can log on to our official website http://www.dinko.es for updates, or

call our hotline +34 93 284 69 62, to obtain the relevant advice and help.

Although we have checked this manual carefully, some mistakes cannot be

avoided, if any inconvenience is caused, please understand. If you find

some mistakes or have better suggestions, you are welcome to get in touch

with us to enhance our further improvement. we will actively adopt you

rational suggestions to ensure that our instrument will be improved

continually to meet your needs.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

3

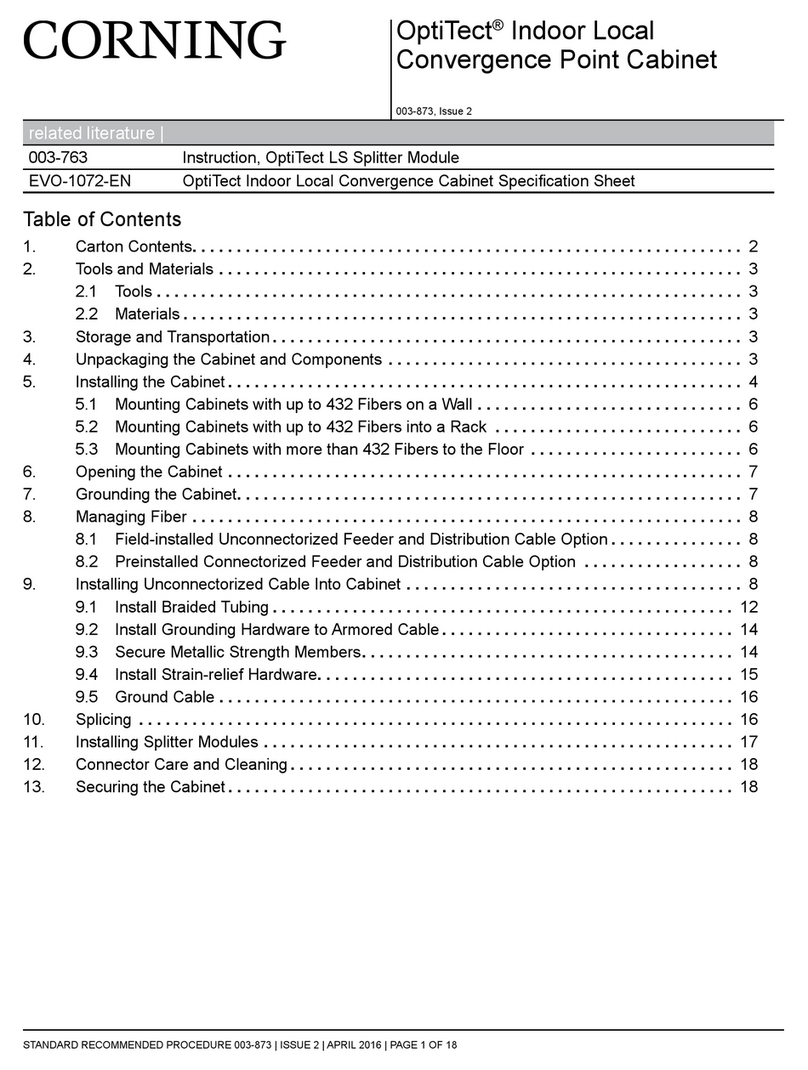

Contents

1. Summary............................................................................................5

1.1 Working Principle .....................................................................5

1.2 Instrument Characteristics.........................................................6

1.3 Application Field.......................................................................7

1.4 Technical Parameters.................................................................8

1.5 Symbols and Prompt Notes .......................................................8

1.6 Brief Introduction of System and Structure ...............................9

2. Installation .......................................................................................10

2.1 Unpacking...............................................................................10

2.2 Installation Condition..............................................................10

2.3 Instrument Installation.............................................................12

3. Operating the Instrument..................................................................12

3.1 Power on Self-test ...................................................................12

3.2 Photometric Analysis...............................................................16

3.2.1 Photometric analysis.......................................................17

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

4

3.2.2 Data processing ..............................................................18

3.3 Quantitative Analysis ..............................................................20

3.3.1 Standard curve test .........................................................21

3.3.2 Application of coefficient method .................................................29

3.3.3 Setting concentration unit..............................................................31

3.4 Spectral Scanning.......................................................................32

3.4.1 Wavelength scan................................................................34

3.4.2 Processing data................................................................374

3.5 Kinetic Analysis.......................................................................429

3.5.1 Kinetic analysis.................................................................41

3.5.2 Processing data................................................................462

3.6 System Settings........................................................................517

3.6.1 Lamps management............................................................ 48

3.6.2 Time Settings.....................................................................50

3.6.3 Dark current calibration...................................................561

3.6.4 Wavelength calibration....................................................572

3.6.5 System debugs.................................................................583

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

5

3.6.6 Restoring defaults............................................................584

4. Routine maintenance........................................................................606

5. Troubleshooting ...............................................................................629

1.Summary

1.1 Working Principle

The working principle of spectrophotometer is mainly based on Lambert -

Bill law. When a bundle of monochromatic light passes through a uniform

colored solution, the absorbance of the solution is proportional to the

product of the concentration of the solution and the optical path,

which is

the true physical meaning of Lambert Bill's law. The law is the basis of

quantitative analysis of photometric analysis, and also the basic principle

of UV-Vis spectrophotometer. The formula for Lambert-Bill law is

expressed as follows:

A=k b C

A--The absorbance of the measured substance solution.

k-- Absorption coefficient of solution.

b--

The thickness of the liquid layer (the optical path of the cuvette or

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

6

absorption pool), cm.

C—The concentration of the measured substance solution.

The premise of satisfying the Lambert Bill law is three hypotheses: First, the

incident light is monochromatic light. Second, the incident light is parallel light.

Third, light-absorbing particles are independent of each other, regardless of

quantity and variety. In addition, the deviation of the law is affected by sample

treatment, the optical path of measure, stray light, noise, the spectral bandwidth,

the chemical factors and other factors. The abovefactors need be taken into account

in the routine tests.

1.2 Instrument Characteristics

The characteristics of UV/VIS 6000 Spectrophotometer are the following:

The stray light is low and resolution is high in optical system, so the

stability and reproducibility are excellent and the readings are accurate.

The design is scientific, new technologies are used to combine the light,

instrument, electricity with computer to make the stability indicators of

the instrument close to or reach the high-level of UVspectrophotometer.

7 inch TFT capacitive touch screen, the touch point is more accurate,

sensitivity is more higher and stability is more better.

High definition resolution (800 * 480), fast running, large capacity for

picture.

Interactive and friendly user interface, and it is easy and fast to be used.

System settings function is powerful, the measurement function of

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

7

photometric analysis, quantitative analysis, wavelength scan and

kinetic analysis can be realized without online operation.

Large data storage: 30 wavelength scan files, 20 kinetic measurement

files, multiple sets of measurement data and standard curves.

Data retrieval and atlas zooming function.

The universal printer (inkjet or laser) can be connected with the

instrument, A4 report output can be completed directly and the report

is more clear and beautiful.

USB transfer function can be achieved; data storage and reading is

more flexible.

1.3 Application Field

Ultraviolet visible spectrophotometer can be widely used in the fields of

pharmacy, medical and health services, chemical engineering, energy,

machinery, metallurgy, environmental protection, geology, food, biology,

materials, agriculture, forestry, fisheries and other industries, and plays an

important role in teaching and research of higher education, measurement

science and research institutes, quality control in the production, raw

materials and product analysis, and is commonly used in physicochemical

laboratory. UV/VIS 6000 is a UV spectrophotometer with touch screen.

The instrument is stable, accurate and powerful and has obvious

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

8

advantages in the fields of scientific research and quality control.

1.4 Technical Parameters

Type UV/VIS 6

Wavelength range (nm) 19 -11

Spectral bandwidth (nm) 1,8 nm

Wavelength accuracy (nm) ± .5

Wavelength repeatability

(nm) ≤ .2

Photometric range -2 %T、- .3-3A、-9999C

Photometric accuracy ± .4 %T

Stray light ≤ . 7 %T

Size (mm) 46 ×38 ×18

1.5 Symbols and Prompt Notes

:

Power supply,

beware of electric shock.

: Heat source, burn carefully.

: UV light source, be careful radiation.

: Notice.

: Special note.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

9

1.6 Brief Introduction of System and Structure

1、The shape and structure of the instrument

The shape and structure of the instrument is shown in figure 1:

1 2 3

1--Hand pull rod 2—Sample room 3--Touch screen

Figure 1 The shape of UV/VIS 6000

The back of the UV/VIS 6000 instrument is shown in figure 2:

1—Power switch 2-- Power supply socket 3-- Cooling vent

4-- Printer port

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

10

Figure 2 The back of UV/VIS 6000

2.Installation

Please read the contents of this chapter carefully before installation.

2.1 Unpacking

Please check to make sure that the instrument external packing is intact and

has no opened marks before unpacking. After unpacking, please inspect to

make sure the instrument has no damage and the accessories is complete

by referring to the packing list in the manual (page thirty-fifth of this

manual). If you have any question, please consult the dealer or

manufacturer. If you find any damage or loss in the package, please inform

the manufacturer immediately.

2.2 Installation Condition

The following requirements should be met for the installation of the

instrument:

1) The requirements of temperature and humidity:

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

11

The equipment should be placed in a dry room with temperature within

the range of 15 °C to 35 °C and relative humidity less than 85%.

2) Power requirements:

The rated voltage of the instrument is 220 V + 22 V AC (or 110 V + 11

V AC), the frequency is 50 Hz (or 60 Hz), and a good grounding wire

should be installed. More than 1000W electronic AC voltage stabilizer

is recommended to enhance the anti-interference performance of the

instrument.

3) Other working conditions:

A position not subject to strong vibration, or any continuous (even

weak) vibration.

A position not exposed to direct sunlight and disturbed by air flow.

A location free from exposure to corrosive gas, or dust.

A position free from strong magnetic, electromagnetic fields and

high frequency electromagnetic wave.

Make sure that the bench or table used to support the instrument is

comfortably able to withstand the load, more than 15 cm of space at

the rear away from the wall for effective ventilation.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

12

2.3 Instrument Installation

Installation procedures of the instrument are as follows:

1) Place the instrument on a stable bench after unpacking.

2) Connect instrument power cord. If equipped with a printer, connect

wiring between the instrument and printer and printer power cord.

3.Operating the Instrument

Please inspect all connections, ensure the connections are correct. The

power supply needs to meet the requirements and have reliable ground

connection. Ensure light path is expedite (no blocking object in sample

room). Ensure all other conditions are correct before the boot.

3.1 Power on Self-test

1. Powering on

After the instrument is connected to power, start up the instrument and

the welcome interface is displayed, as shown in figure 3.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

13

Figure 3 The welcome interface

2. Self-check

The instrument starts self-check after displaying the welcome interface

several seconds. The lamp conversion, filter, detector, deuterium lamp,

tungsten lamp, wavelength calibration, battery, system parameters and

dark current are detected automatically. The self-check interface of the

UV/VIS 6000 Spectrophotometer is shown in figure 4.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

14

Figure 4 The self-checking interface

If the self-checking is passed successfully, the status indicator light is green. If

a self-checking error occurs, the buzzer alarm will automatically happen, the status

indicator light will be red, and the next self-checking content will be carried out

generally.

Please do not open the cover of sample chamber when self-checking. Please

contact the manufacturer in time, or judge and remove the fault according to the "5

common faults and exclusions" when the self-checking fails.

3. Pre-warming

Pre-warming starts after self-check (Figure 5).

The default time of pre-warming is 20minutes, the buzzing will appear

automatically and the instrument enters the main interface after pre-

warming.

Figure 5 Pre-warming interface

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

15

The electronic components need to be preheated for a certain period of time to

reach a stable state after powering on the instrument. In addition, deuterium lamp

also takes some time to reach thermal equilibrium, so it is recommended that the

instrument starts to test after pre-warming for 20 minutes.

4. Pending operation

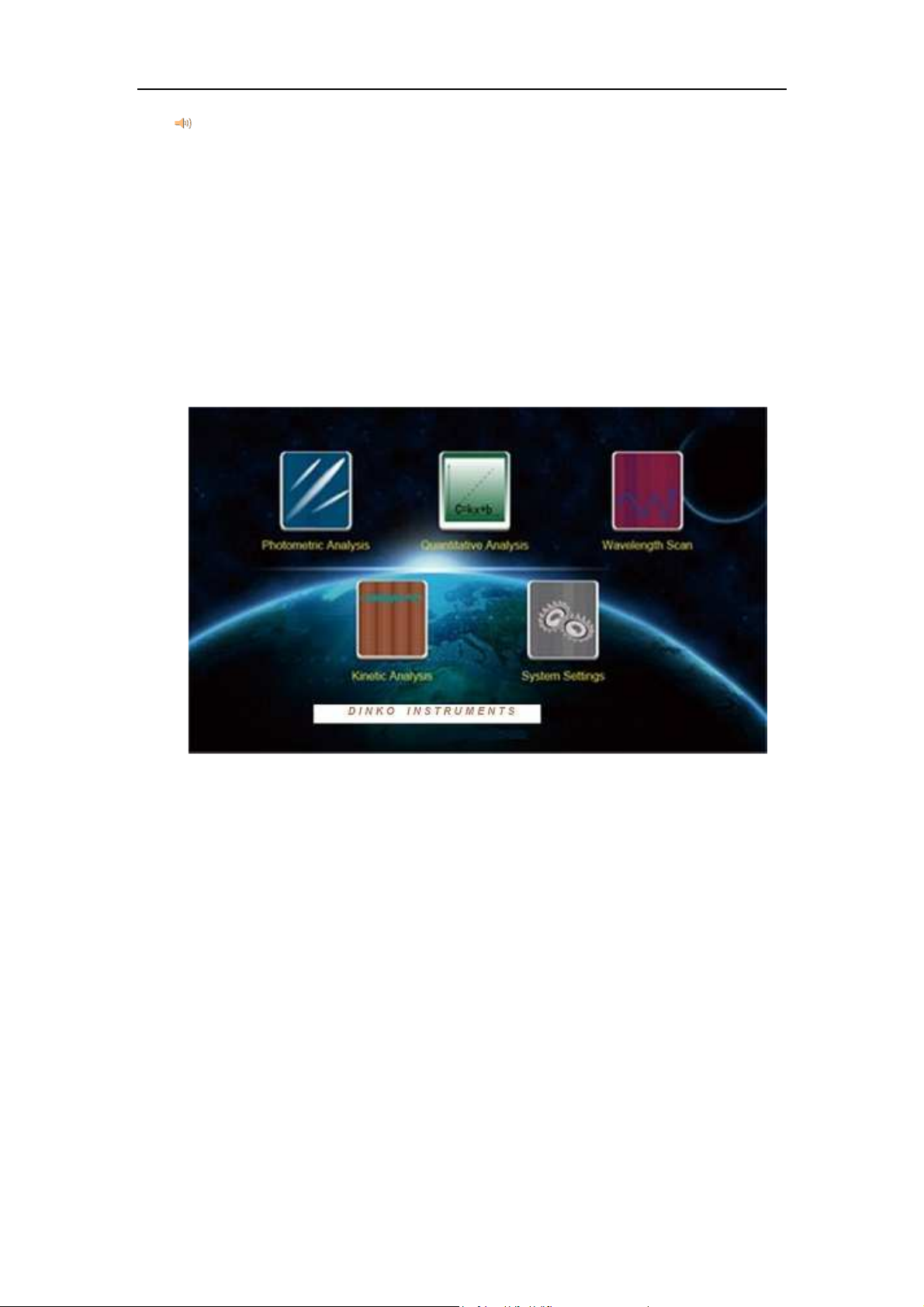

The main operation interface appears after pre-warming, as shown in

figure 6.

Figure 6 The operation main interface

Photometric analysis, quantitative analysis, wavelength scan, kinetic

analysis and system settings can be realized by the UV/VIS 6000. Click

the required functional modules, you can enter the corresponding

operation interface.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

16

3.2 Photometric Analysis

At the interface of photometric analysis, the user can measure the

absorbance, transmittance and energy at fixed wavelengths, and also print

the measurement results.

Click icon at the operation main interface to enter the interface of

photometric analysis (Figure 7).

Figure 7 The interface of photometric analysis

After entering the functional interface, the real-time display column is in

the upper part of the screen, the main area of the window is the data

recording area, and touch button operation area is on the right side of the

screen. The specifications of touch button are as follows:

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

17

: used to set wavelengths.

: used to calibrate 0 Abs and 100%T, and correct the blank.

: used to measure and record data.

: to save data.

: to load and print data.

: to clear all displayed data.

: to quit the current interface and return to the last interface.

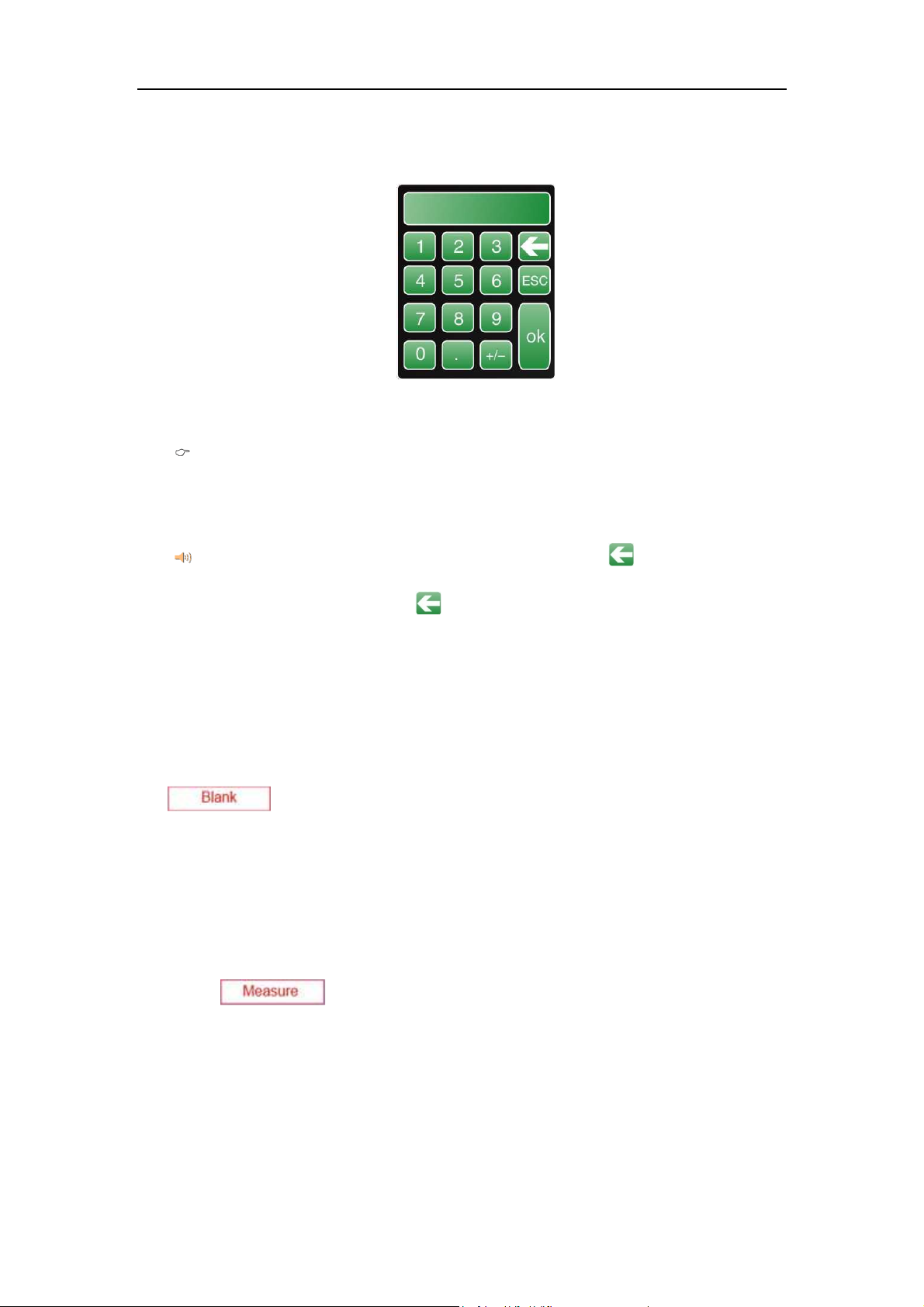

3.2.1 Photometric analysis

The specific steps of photometric analysis are as follows:

1) Entering photometric interface

Click icon at the operation main interface to enter the interface

of photometric analysis.

2) Setting test wavelength

Click button at the interface of photometric analysis, the

digital input window appears (Figure 8). Input the wavelength value,

click " " to confirm the value, the indication of "wavelength shift......"

appears below the screen, then the instrument reaches the specified

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

18

wavelength.

Figure 8 Digital input window

The wavelength input range of the UV/VIS 6000 is 190 nm~1100 nm. If the

input value is out of the range, the data is considered invalid and needs to be

reentered.

If the input wavelength is found to be incorrect, click " " to clear the current

data and reenter. Touch button " " has the same function in the following data

input process.

3) Sample test

First, put the blank sample or reference solution in the optical path, click

button to set absorbance/ transmittance of the blank

sample or reference solution as 0 Abs/100.0%T at the current test

wavelength. Second, take out the blank sample or reference solution

from the optical path, put the determined solution into the optical path,

click button, then record the measured results of sample.

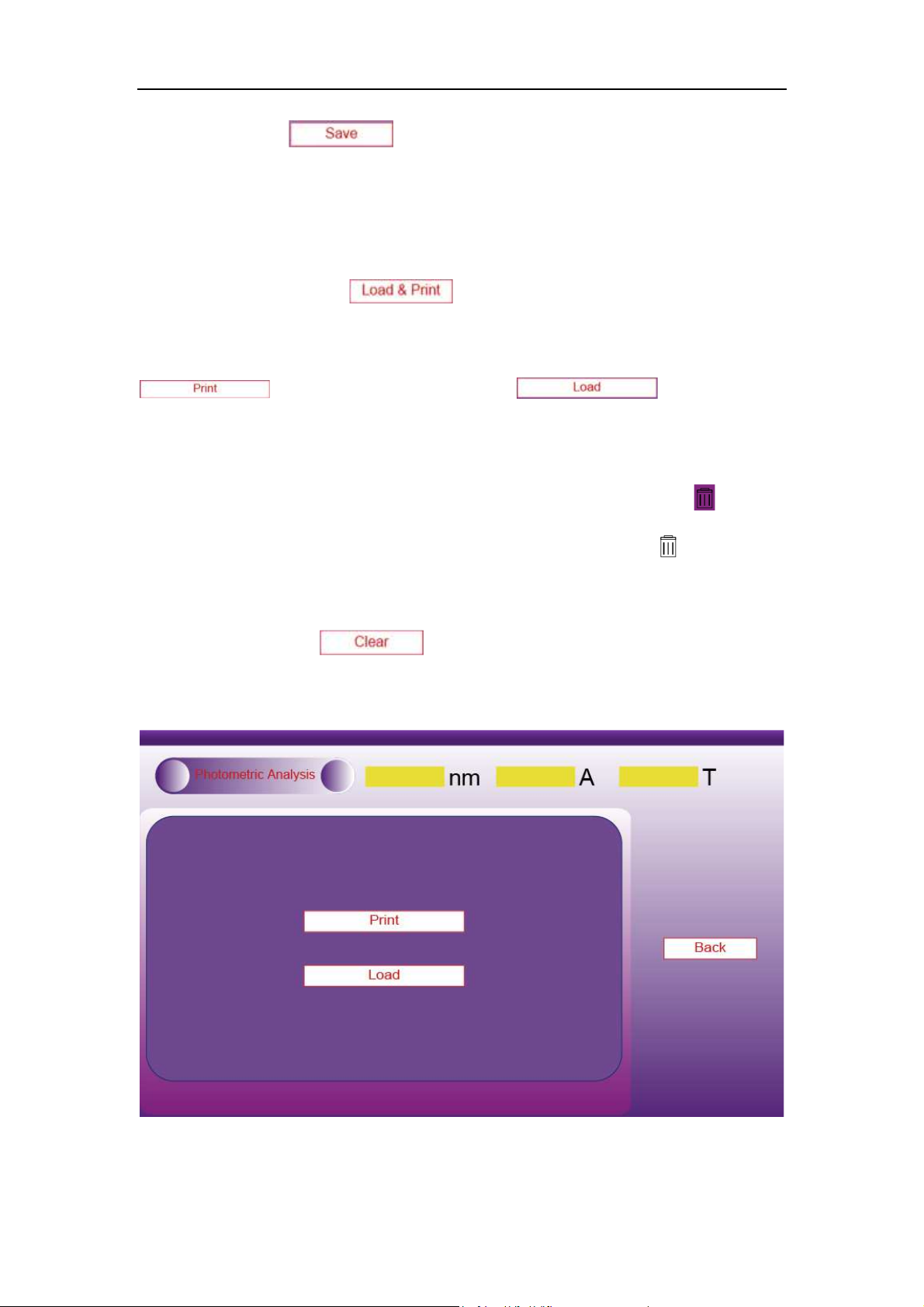

3.2.2 Data processing

The user can save, load, print and delete the data after photometric analysis.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

19

Save data: click button to save data to the host, and the data

is automatically saved to the USB memory if the USB memory is

connected.

Load data, print: click button to enter printing and loading

data operations interface (Figure 9). When the printer is connected, click "

" to print the data, click "

" to open the

saved data. ".

Clear data: when the user needs to delete individual data, click icon at

the lower left corner of the screen to activate it (showing ), then click

the number of data needing to be deleted to delete the corresponding data.

Users can also click button on the right of the screen to empty

all data in the data table.

DINKO

INSTRUMENTS

User’s Manual UV/VIS 6000

20

Figure 9 Photometric analysis—the operation interface of printing and loading data

Once the user deletes the individual data, the clear touch button should be frozen

in time (click “ ” to make it show “ ”) to avoid misoperation in subsequent

operations. The delete operation is only valid for the current display, the saved data will

not be lost. If the user needs to save the deleted data, click button to

overwrite the saved data.

3.3 Quantitative Analysis

In the functional interfaces of quantitative analysis, users can use standard

curve method to determine unknown samples (The standard curves are got

through several standard samples, and unknown samples are measured by

comparing with standard curves). The unknown sample can also be

measured by the coefficient method (The slope and intercept of the

standard curve are known, and the unknown sample is measured directly

by this standard curve).

Click icon at the main operation interface of instrument

operation to enter interface of quantitative analysis (Figure 10).

Table of contents

Other DINKO Instruments Laboratory Equipment manuals