vi | P a g e

V1.0

TABLE OF CONTENTS

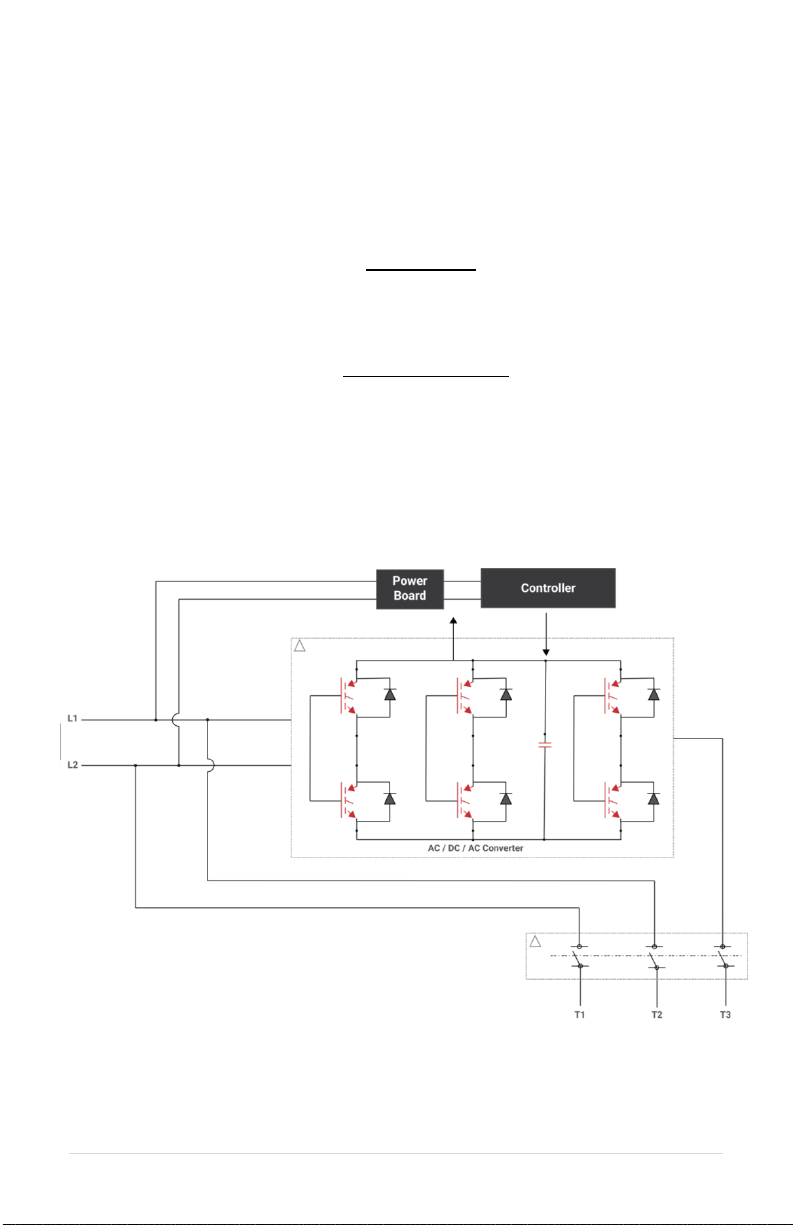

THEORY OF OPERATION ..........................................................................................1

BLOCK DIAGRAM........................................................................................................1

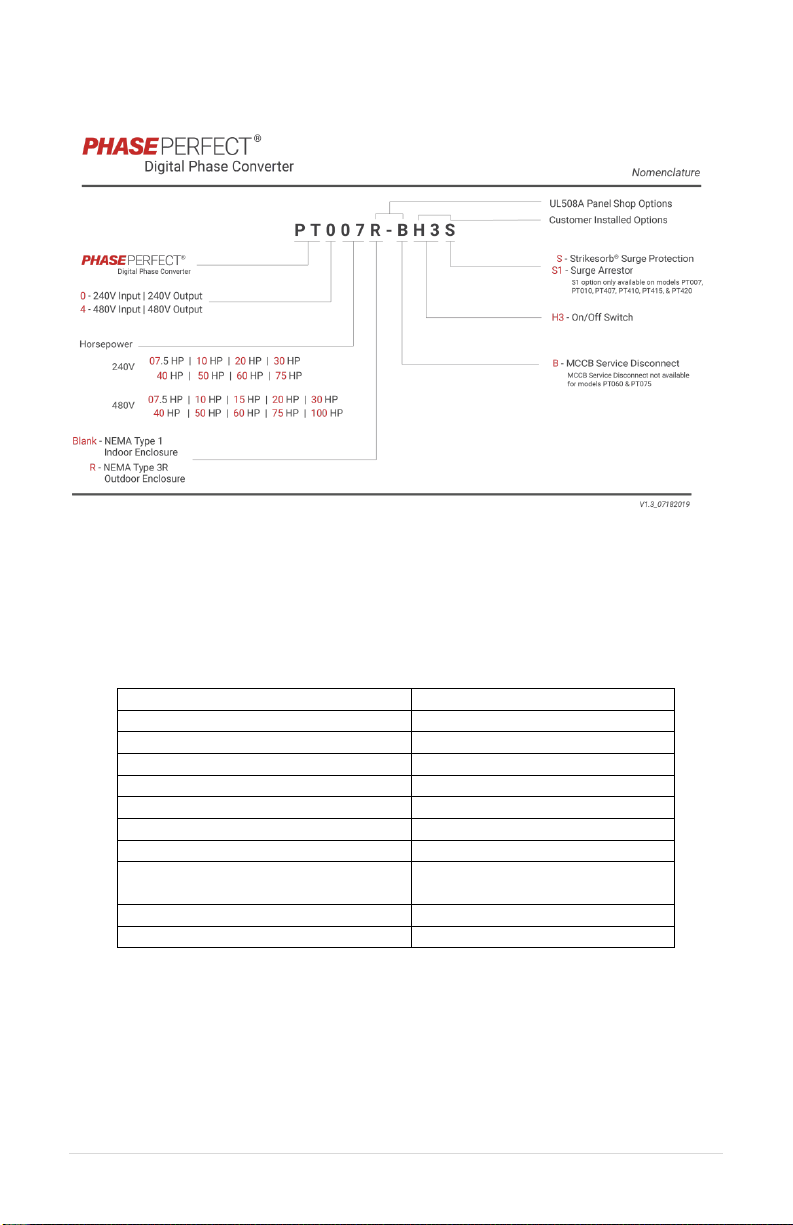

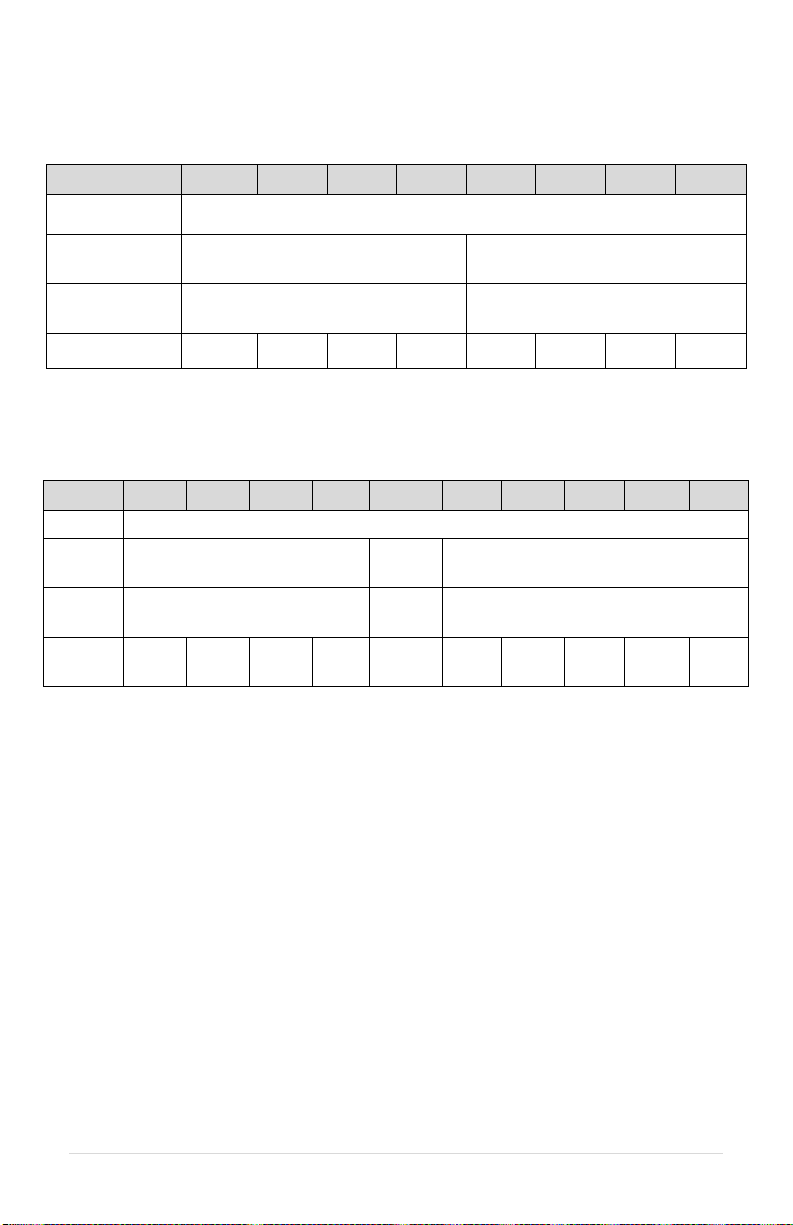

MODELS AND RATINGS ............................................................................................2

SPECIFICATIONS .......................................................................................................2

GENERAL SPECIFICATIONS .........................................................................................2

ELECTRICAL SPECIFICATIONS .....................................................................................3

MECHANICAL SPECIFICATIONS ....................................................................................4

DIMENSIONAL DRAWINGS ...........................................................................................5

INSTALLATION...........................................................................................................8

MOUNTING YOUR NEW PHASE PERFECT .....................................................................8

MOUNTING BRACKET INSTALLATION ............................................................................8

PROPER VENTILATION................................................................................................8

SERVICE ENTRANCE EQUIPMENT ................................................................................8

SOURCE BRANCH CIRCUIT PROTECTION......................................................................8

GROUNDING..............................................................................................................9

WIRE SIZING ...........................................................................................................11

CONNECTING THE LOAD ...........................................................................................11

CONNECTING TO FIELD WIRING TERMINALS...............................................................14

ROUTING POWER CABLES ........................................................................................15

ON/OFF CONTROL WIRING......................................................................................16

OPERATION..............................................................................................................17

LCD STATUS SCREEN..............................................................................................17

DIP SWITCH SETTINGS ...........................................................................................18

AUXINPUTS BYPASS...............................................................................................18

VFD MODE .............................................................................................................18

FAULTS WITH AUTO-RESTART...................................................................................19

FAULTS:MANUAL RESTART ......................................................................................20

FAULT LOG..............................................................................................................20

TROUBLESHOOTING TIPS......................................................................................21

ROUTINE INSPECTION AND MAINTENANCE.........................................................22

LINE FILTER CAPACITORS.........................................................................................22

FUSES ....................................................................................................................24

MOTOR STARTING/OVERLOAD CAPABILITIES ....................................................25

DEFINITIONS & ABBREVIATIONS...........................................................................27