5

Xitanium LED Xtreme SR drivers

Lifetime 100kHrs •

Surge Immunity 8kV CM / 10kV CM / 6kV DM) •/-/•

1-10V

LineSwitch Single-Step / 3-Step

Adjustable Output Current (AOC)

SimpleSet®

Constant Light Output, full (CLO)

Dynadimmer 5-step, no light turn-off

Diagnostics, full

Module Temperature Protection (MTP)

ThermalGuard

Driver Temperature Limit (DTL)

DALI communication protocol

Mains voltage dimming (AmpDim)

MainsGuard

DC Emergency (DCemDim)

Adjustable Startup Time (AST)

Reset LED module operating hours

Dynadimmer 5-step incl. light turn-off

Dynadimmer LITE 1-step, no light turn-off

Constant Light Output, basic (CLO LITE)

OEM Write Protection (OWP)

Diagnostics, basic

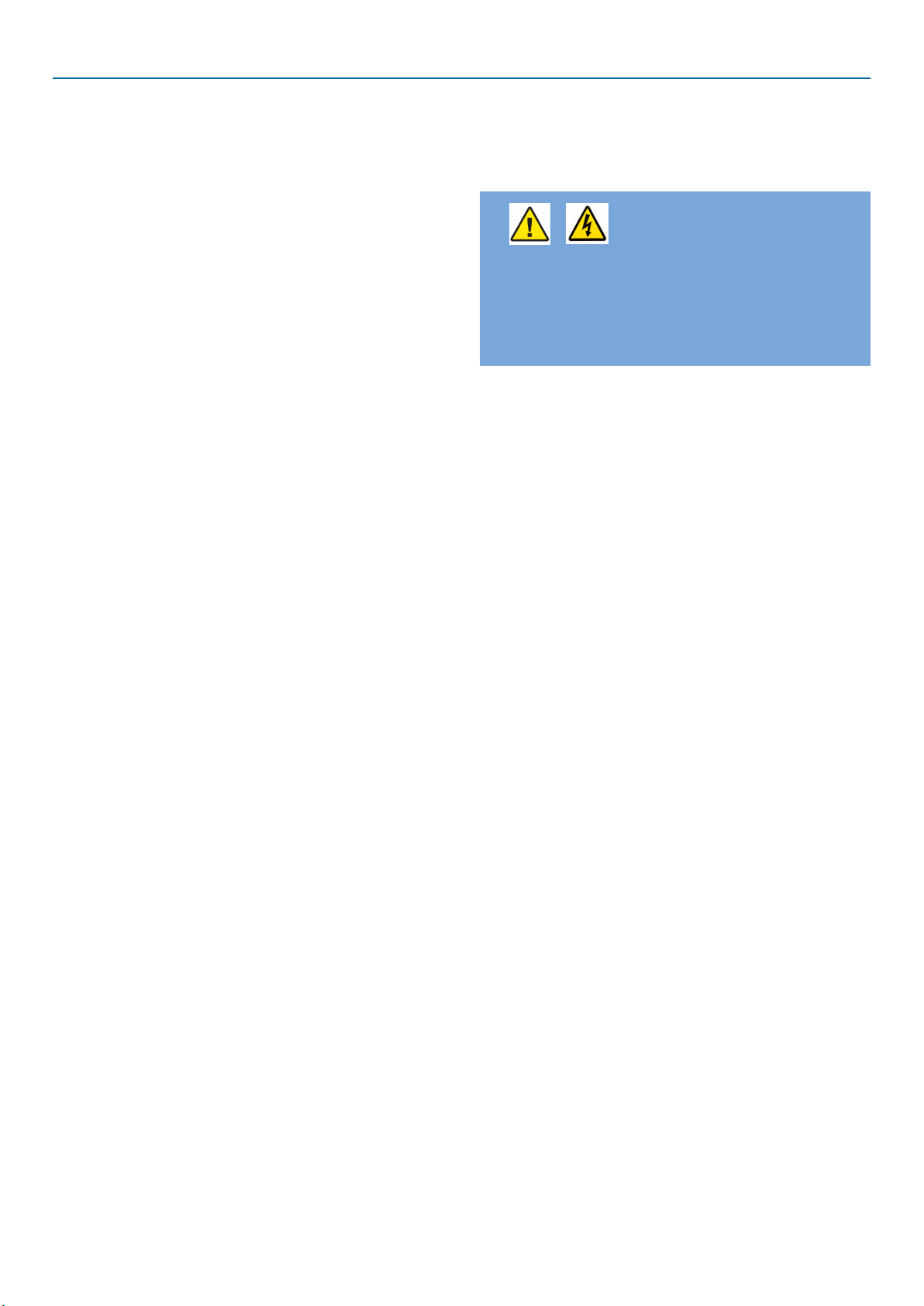

Xitanium LED Xtreme SR drivers and Certified Products

The Xitanium SR drivers offer great benefits for Lighting Management

Systems. To ensure full component interoperability, Philips provides SR

Certification. The performance of SR products is tested and certified to

eliminate any interface problems. This means you can offer connected

lighting solutions without having to worry about software capabilities

and system investments. We have a growing list of SR Certified

Products that are compatible with Philips Xitanium SR LED drivers.

They cover a wide range of connected lighting solutions from trusted

providers of sensor and connectivity modules, building management

systems and city management systems. To support the development of

SR Certified Components, Philips has launched the SR Partner Program.

SR partners receive all required details of the Xitanium SR driver

interface for electrical and DALI data exchange protocols. Philips also

provides test and verification tests and successfully tested products can

be recognized via the SR Certified logo:

Xitanium LED Xtreme SR driver versions

The Xitanium LED Xtreme SR drivers described in this guide are

available in multiple power and current ratings which enable the most

popular light output levels for outdoor and industrial applications. It is

always highly recommended to check our latest Xitanium LED Xtreme

SR driver leaflet for the most up-to-date overview of our range. This

leaflet can be downloaded at www.philips.com/oem.

Detailed driver specifications can be found in the Xitanium

LED driver datasheets which can be downloaded at www.philips.com/

oem. Product specifications and datasheets can be accessed via the

Easy Design-in tool at www.easydesignintool.com.

Configurability Interface (tooling)

The Xitanium LED Xtreme SR drivers are configurable. A large

package of features and parameters in these drivers can be set via a

specific tool. This tool is the MultiOne Configurator. There are two

types of interfacing technology used to communicate with this tool:

•Wired: SR (DA+/DA-) interface (based on DALI 2 protocol)

•Wireless: SimpleSet

SimpleSet

Philips SimpleSet new wireless programming technology allows

luminaire manufacturers to quickly and easily program Xitanium

LED Xtreme SR drivers in any stage during of the manufacturing

process, without a connection to mains power, offering great

flexibility. As a result, orders can be met faster while reducing

cost and inventory.

For more information, please visit www.philips.com/multione or

contact your local Philips representative.

•

•

•

•

•

•

•

•

•

•

•

•

•

Design-in Guide - Philips Xitanium LED Xtreme SR driver

Xitanium LED Xtreme SR driver: general feature overview

Please refer to the applicable driver datasheet for an exact feature overview

•

DALI interface