CF 3000

6PHOENIX CONTACT 102649_en_02

Table of Contents

1 Basic instructions .......................................................................................................................7

1.1 Intended purpose .................................................................................................7

1.2 Work sites..............................................................................................................8

1.3 For your safety.......................................................................................................8

2 Description of the CF 3000 ........................................................................................................9

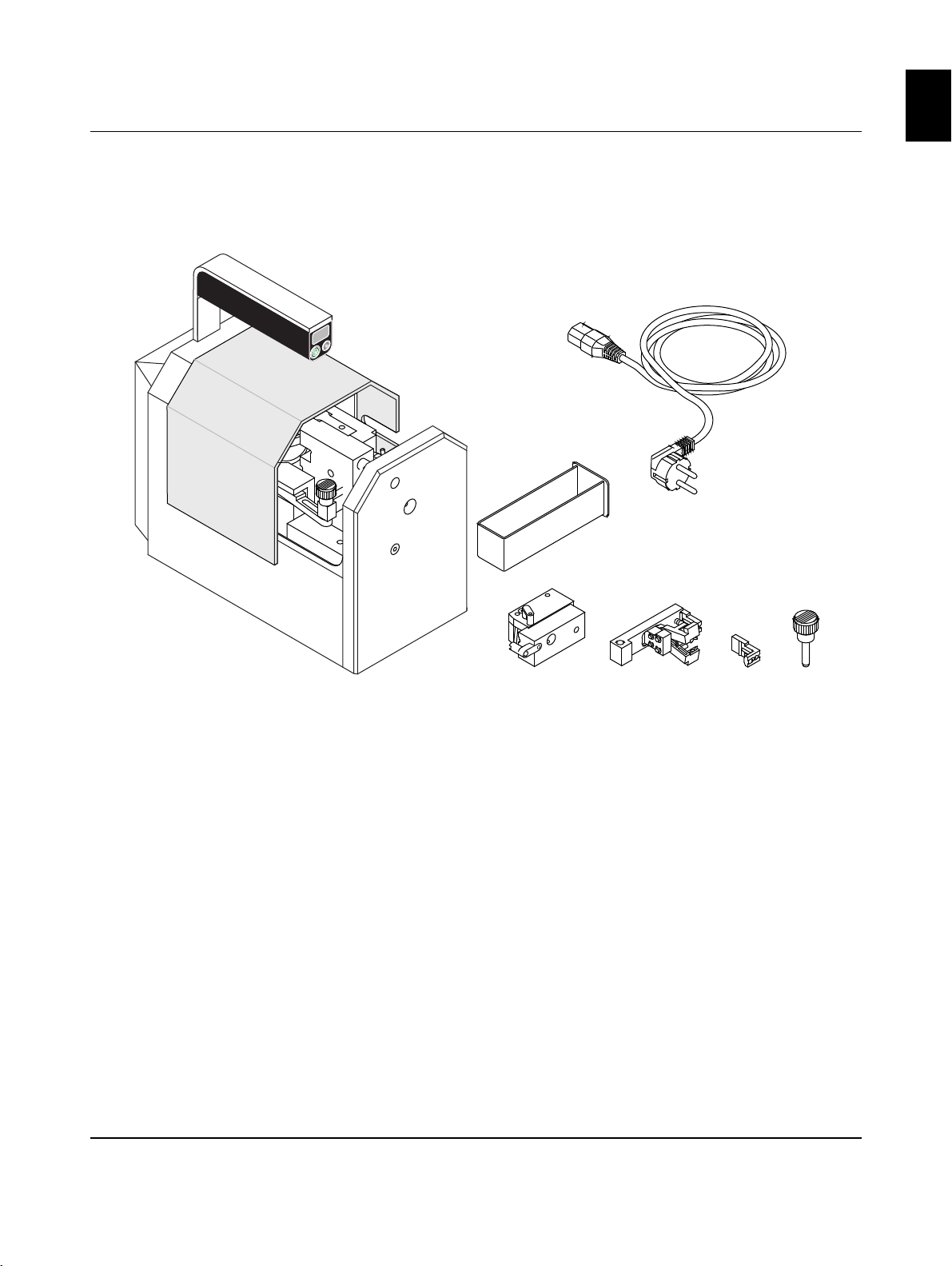

2.1 Scope of delivery ...................................................................................................9

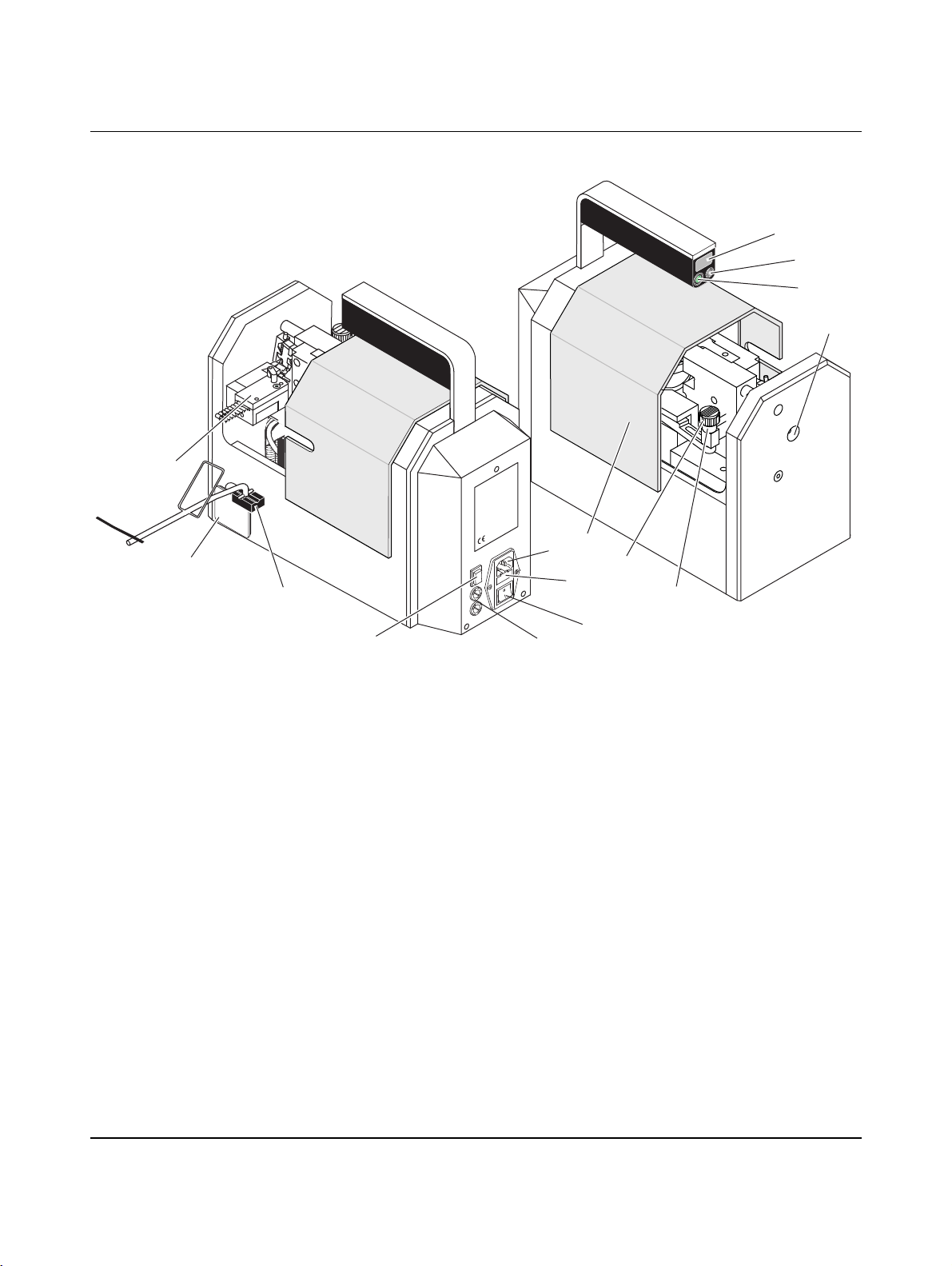

2.2 Overview of the operating components ...............................................................10

3 Putting into operation ...............................................................................................................11

3.1 Selecting the installation site................................................................................11

3.2 Preparing the dispenser.......................................................................................11

4 Operation .................................................................................................................................13

4.1 Stripping and crimping.........................................................................................13

4.2 Converting to other cross-sections ......................................................................14

4.3 Service ................................................................................................................16

5 Rectifying malfunctions ............................................................................................................17

5.1 Maintenance position...........................................................................................17

5.2 Fault cases ..........................................................................................................17

5.3 Fault case 1 .........................................................................................................17

5.4 Fault case 2 .........................................................................................................18

5.5 Fault case 3 .........................................................................................................18

5.6 Fault case 4 .........................................................................................................19

5.7 Fault case 5 .........................................................................................................19

5.8 Fault case 6 .........................................................................................................20

5.9 Fault case 7 .........................................................................................................20

A Technical Annex .......................................................................................................................21

A 1 Technical data .....................................................................................................21

B Order data ................................................................................................................................21

B 1 Stripping and crimping automat ...........................................................................21

B 3 Spare parts..........................................................................................................22