Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

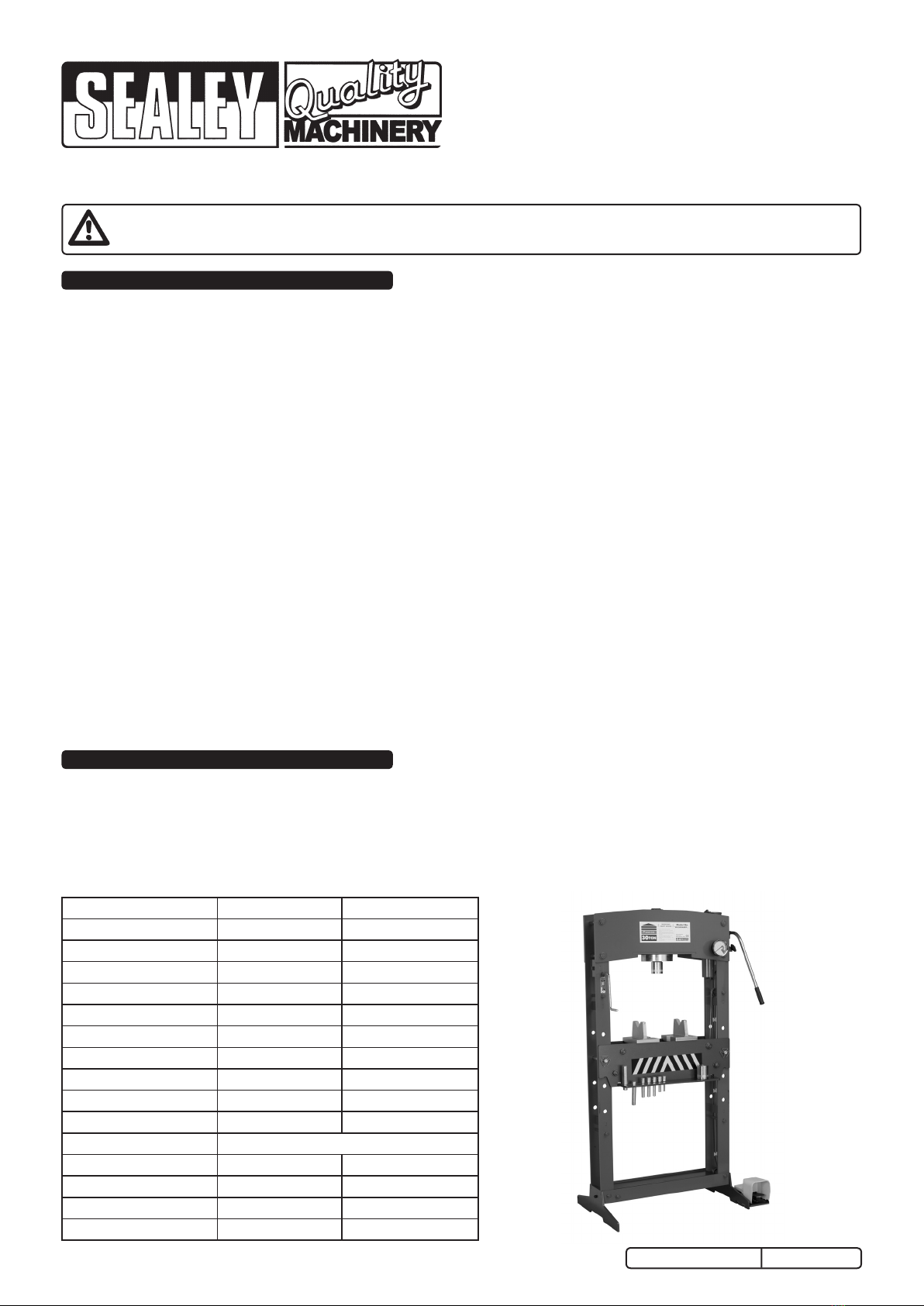

2. INTRODUCTION & SPECIFICATIONS

Models: YK30FAHFP.V2, YK50FAHFP.V2

1. SAFETY INSTRUCTIONS

Heavy-duty press frame with integrally mounted air motor powering reliable hydraulic pump unit, which can be foot operated. Reinforced frame

head fitted with sliding hydraulic ram assembly giving 250mm of lateral travel for off-centre pressing applications. Fitted with ram pressure

gauge and table winch, aiding exact alignment of the ram head and workpiece. Supplied with pair of V-blocks/pressing plates and seven

pressing pins ranging from 3 to 20ton which are stored on table mounted tool shelf.

WARNING! All models are purpose designed to withstand greater loads than the hydraulic units can develop. For safety reasons, always

ensure the workpiece is secured on the table to ensure loads that flex will not suddenly “give” causing danger to operator or damage to

component.

1.1 GENERAL SAFETY

Familiarise yourself with this products application and limitations, as well as the specific potential hazards peculiar to the press.

Maintain the press in good condition (use an authorised service agent).

Replace or repair damaged parts. Use recommended parts only. Non authorised parts may be dangerous and will invalidate the warranty.

Keep the press clean for best and safest performance.

Locate the press in an adequate working area for its function, keep area clean and tidy and free from unrelated materials, and ensure

there is adequate lighting.

Ensure the workpiece is correctly secured before operating the press.

WARNING! Always wear approved eye or face protection when operating the press.

Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain long hair.

Keep hands and body clear of the work table when operating the press.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non slip shoes.

Keep children and unauthorised persons away from the working area.

DO NOT operate the press if any parts are missing as this may cause failure or possible personal injury.

DO NOT force the press to achieve a task it was not designed to perform.

DO NOT adjust or tamper with the safety valve.

DO NOT exceed the rated capacity of the press.

DO NOT apply off centre loads.

DO NOT allow the workpiece or the arbor plates to fall from the press working bench.

DO NOT get the press wet or use in damp or wet locations or areas where there is condensation.

DO NOT operate the press when you are tired, under the influence of alcohol, drugs or intoxicating medication.

When not in use release pressure from the pump and clean the press. Stand or store the arbors in a safe location.

WARNING! Always position the press against a wall. If the press is situated in the open workshop, it is essential that a guard be

placed at the rear of the unit. This will prevent injury to bystanders in the event of the work piece ejecting suddenly.

WARNING! The warnings, cautions and instructions in this manual cannot cover all possible conditions and situations that

may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this

product, but must be applied by the operator.

DANGER! The press is top heavy. If it requires moving after assembly or for relocation, use suitable slings around the top crossbeam, or

lift direct with a forklift with the forks located under the top crossbeam. DO NOT use a pallet truck.

INSTRUCTIONS FOR:

AIR HYDRAULIC FLOOR PRESS

YK30FAHFP.V2 & YK50FAHFP.V2 Issue No: 1 - 02/12/08

Model: YK30FAHFP.V2 YK50FAHFP.V2

Capacity 30ton 50ton

Ram Stroke 120mm 120mm

Extension Screw 75mm 75mm

Lateral Ram Travel 250mm 250mm

Max Ht-Ram to Table 700mm 720mm

Min Ht-Ram to Table 150mm 155mm

Table Aperture 170mm 170mm

Work Table Depth 190mm 190mm

Work Table Width 710mm 710mm

Overall Height 1830mm 1910mm

Press Pins 3, 8, 12, 14, 16, 18, 20ton

Gauge Included Yes Yes

Weight 242kg 244kg

Working Pressure 100 - 145psi 100 - 145psi

Air Consumption 9.5cfm 9.5cfm

YK30FAHFP.V2