9Copyright © 2010 PhotoShip One LLC - www.PhotoShipOne.com

FINAL ASSEMBLY

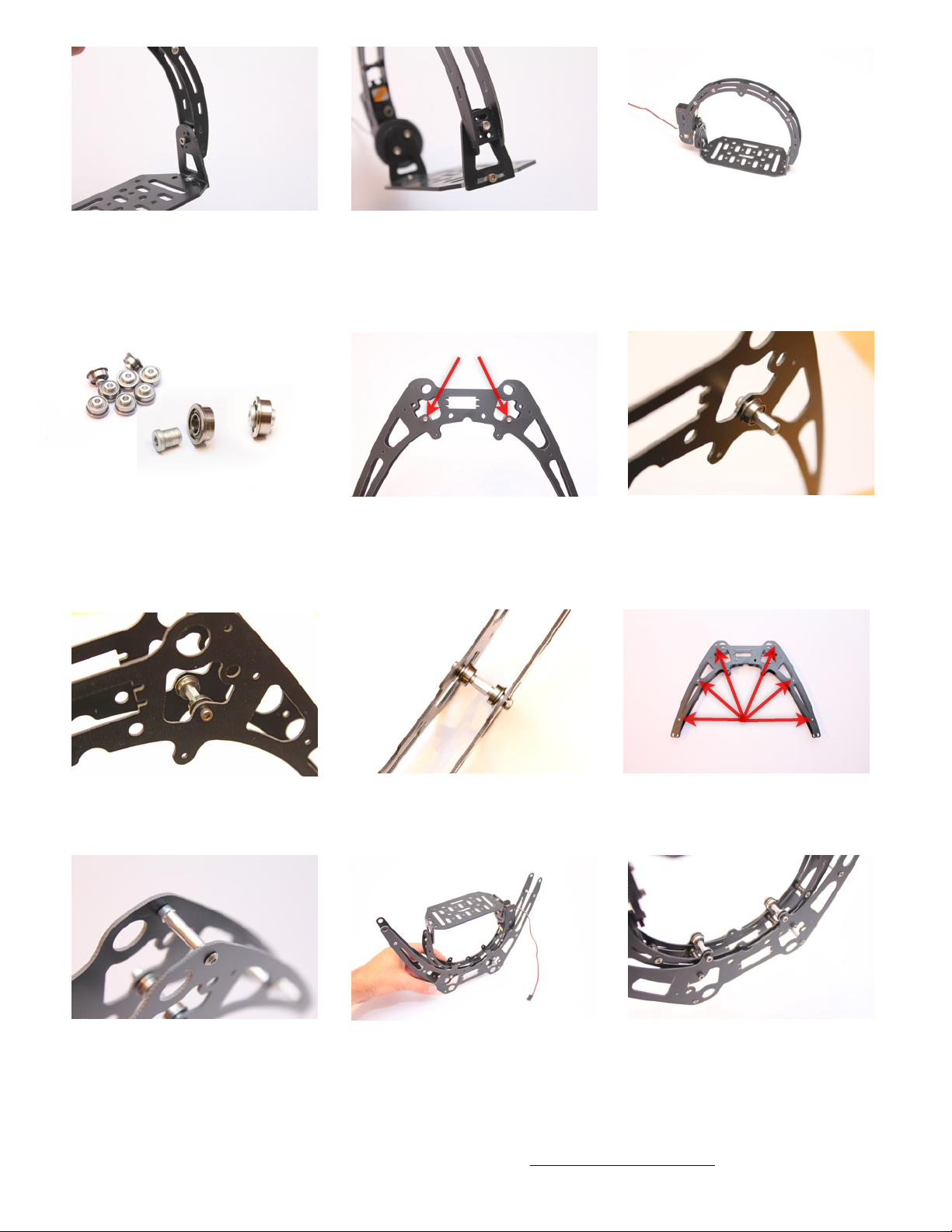

Install four rubber grommets into the large holes in the top of the landing skids as shown.

Install the landing skid tubes through the

landing gear legs and secure with the

rubber stoppers. You may need to slightly

files the holes of the skid legs to get the

tubes to slide through.

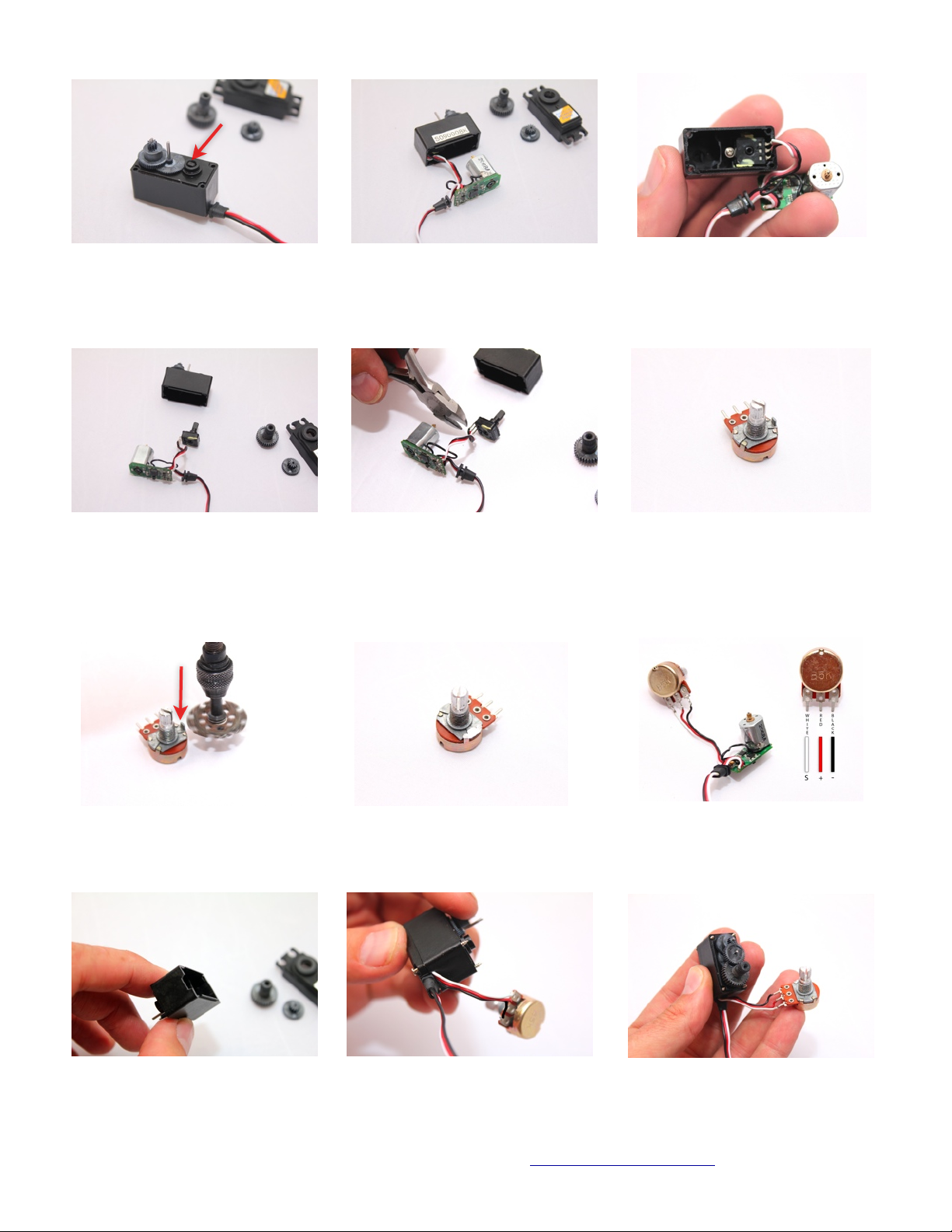

Two carbon tubes, four end fittings and

four pieces of adhesive lined heat shrink

are used in the next steps. The end fittings

may require sanding of the edges to snugly

fit into the carbon tube without splitting it.

Slip a piece of heatshrink over the end and

heat with heat gun or butane lighter. Heat

enough so the adhesive inside the heat

shrink tube begins to show at the ends.

Repeat the process of installing the other

ends on the carbon tubes with heat shrink.

BE SURE BOTH ENDS ARE ALIGNED

WITH EACH OTHER.

Now slide each carbon tube through the

grommets as shown.

When complete the assembly will look like

this.

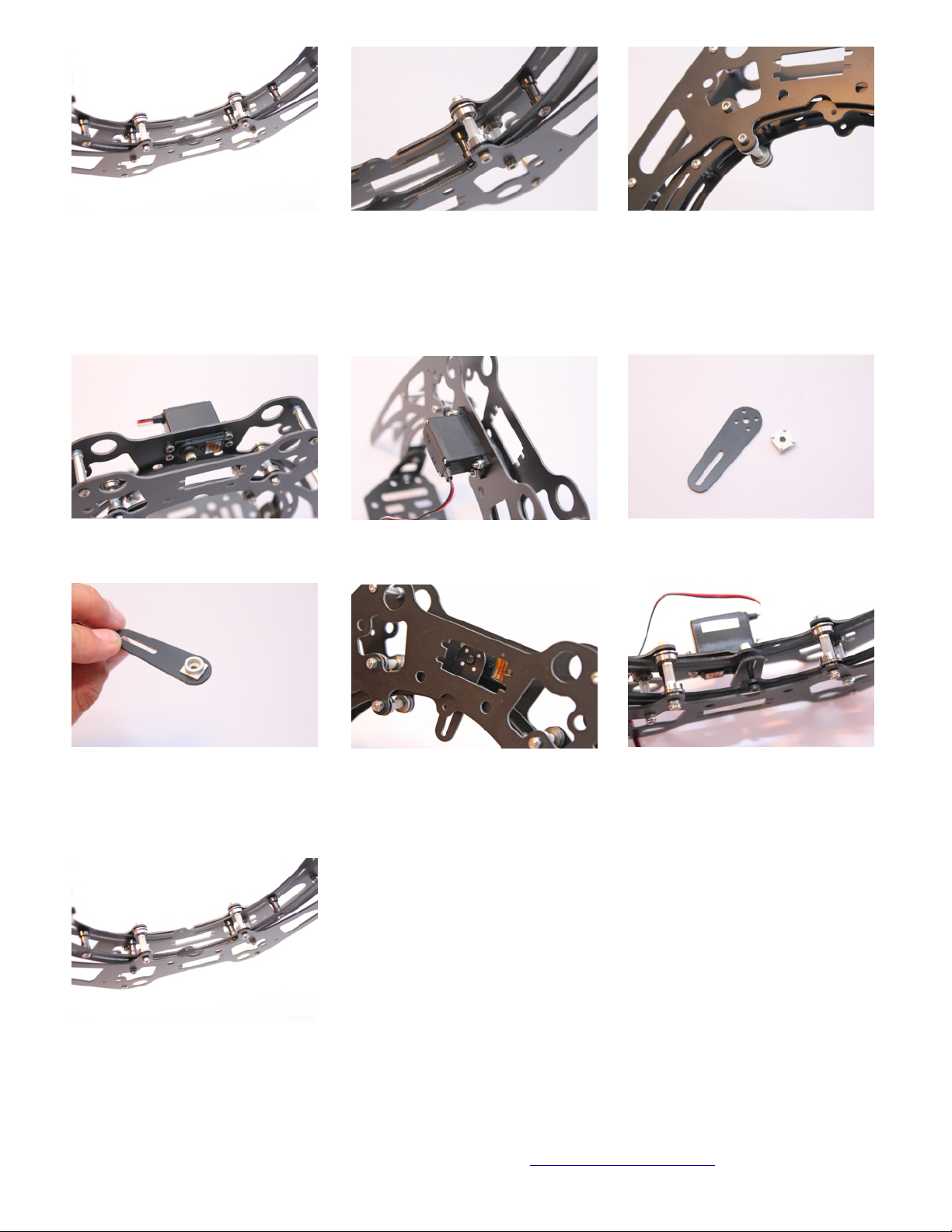

Install the isolators on the carbon tube

ends. Orient them facing downward as

shown.

Now you will install the rubber ball mount

isolators. For cameras over 500gr. You may

fill the inside of the isolators with clear

silicone adhesive. Doing so will double the

weight capacity of the isolators.

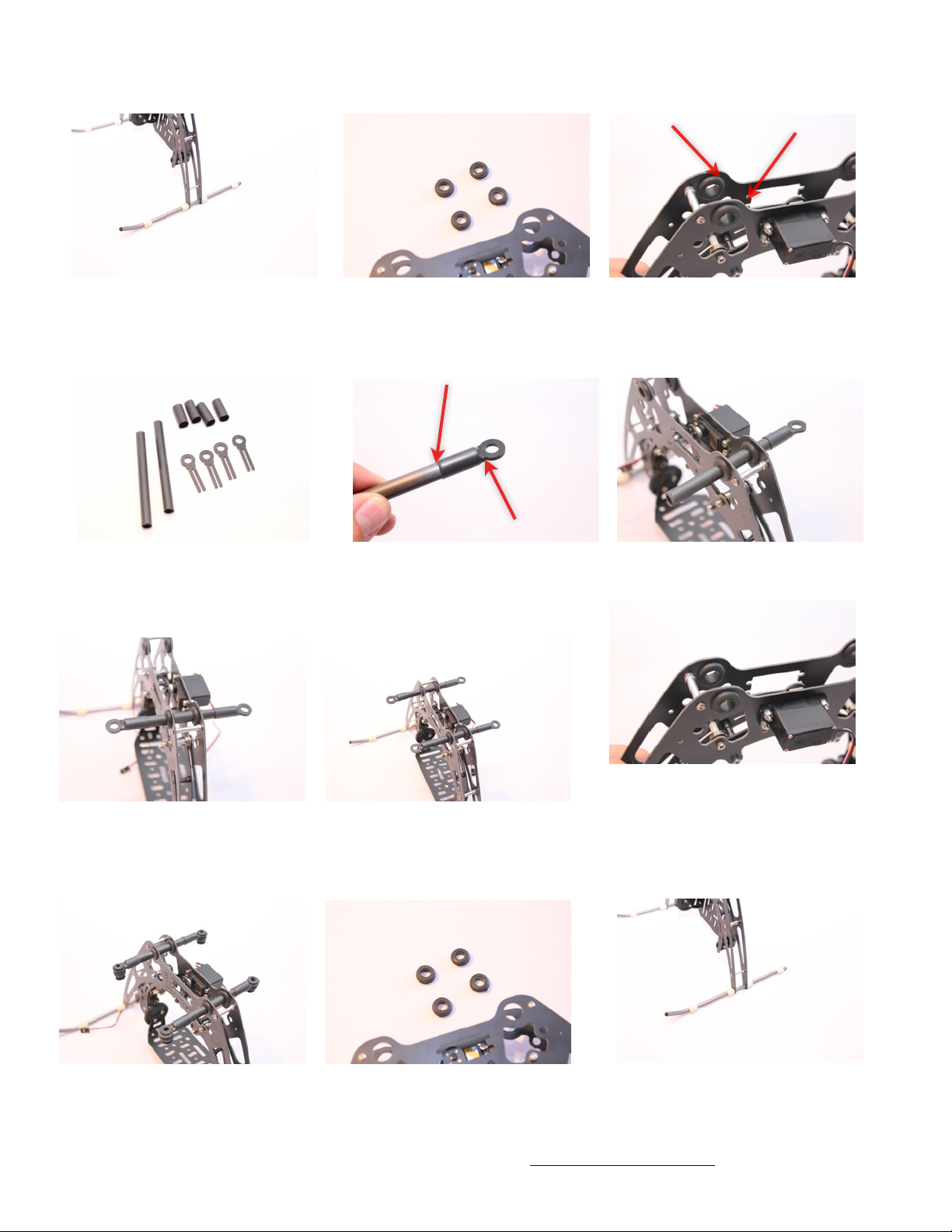

Next install the battery tray plates onto the

opposite end of the rubber ball mounts.

Both battery tray plates shown installed.