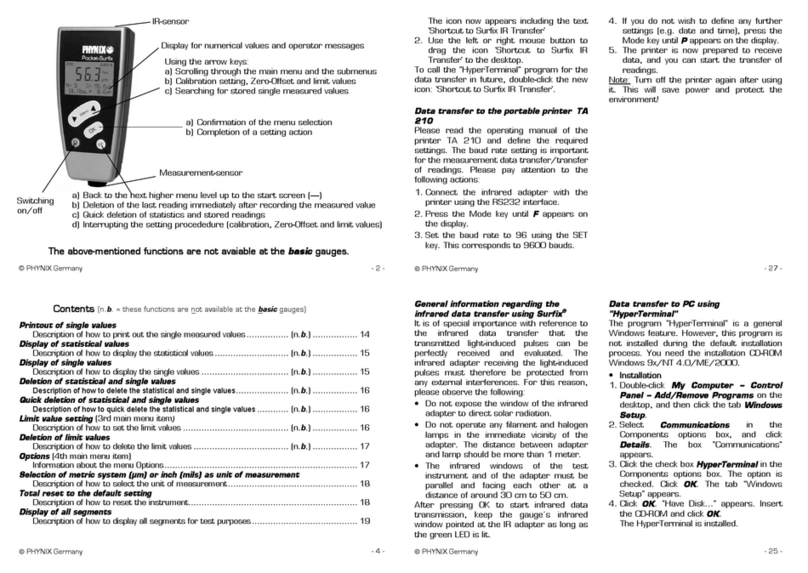

6. Measuring mode (3rd menu item)

...

6.5 SSPC PA2 mode

SSPC PA2 is a standard developed by the Society for Protective Coatings (SSPC) and

describes a procedure for determining conformance to a specified coating dry film

thickness on ferrous and non-ferrous metal substrates using nondestructive coating

thickness gauges described in ASTM D 7091.

The SSPC PA2 mode is a convenient way to measure coating thickness according the

SSPC standard. It can be selected under the menu item “Measuring mode”. It is

indicated by “PA2” in the display.

In fact SSPC PA2 mode is a kind of block value statistics, with a fixed block size of three

values. During measurement all three values of the actual block are shown on the real

time display. Additionally the moving average for this block and the mean value of all

already completed blocks are shown.

At the beginning of each block the first reading is displayed in the center of the display,

after the second measurement the actual reading is displayed there, and the first

reading moves one line down, indiacated by n1. Finally after the third measure¬ment the

last reading is shown in the center, and the two readings before are shown below,

indicated by n1 and n2. On the right side of the display x¯ shows the moving average of

the actual block, and x¯ t the mean value of all blocks.

6.5.1 Activating the SSPC PA2 mode

Procedure:

press this key three times until Measuring mode appears on the

display

press this key; Autom. Detection FN, F, N appears on the display

press this key twice; SSPC PA2 mode appears on the display

press this key; SSPC PA2 mode deactivate appears on the display

press this key; SSPC PA2 mode activate appears on the display.

press this key; SSPC PA2 mode activated appears on the display. As

indicator the PA2 symbol appears on the display.