Empty batteries are indicated by a red or empty battery icon. Please remove used

batteries at once and dispose of them in an environmentally acceptable manner.

When inserting new batteries, please pay attention to the correct polarity. Wrongly

inserted batteries may lead to a destruction of the gauge.

In order to avoid any possible loss of data, please pay attention when exchanging

batteries:

a) Always switch off the gauge by means of the button before exchanging batteries.

b) Exchange the batteries within 20 seconds.

After inserting the batteries and switching-on for the first time by means of the button,

the display shows

a) English as proposed language: confirm with , or use the arrow keys to select

another language and confirm with , after which the display shows

b) the proposed date and time: confirm with , or use the arrow keys to change

and confirm with (pay attention to the instructions on the display).

Normally the gauge works in the automatic switch-off mode. It switches off automatically

90 seconds after the last measurement or operation. For permanent opertion mode see

chapter 9.1.

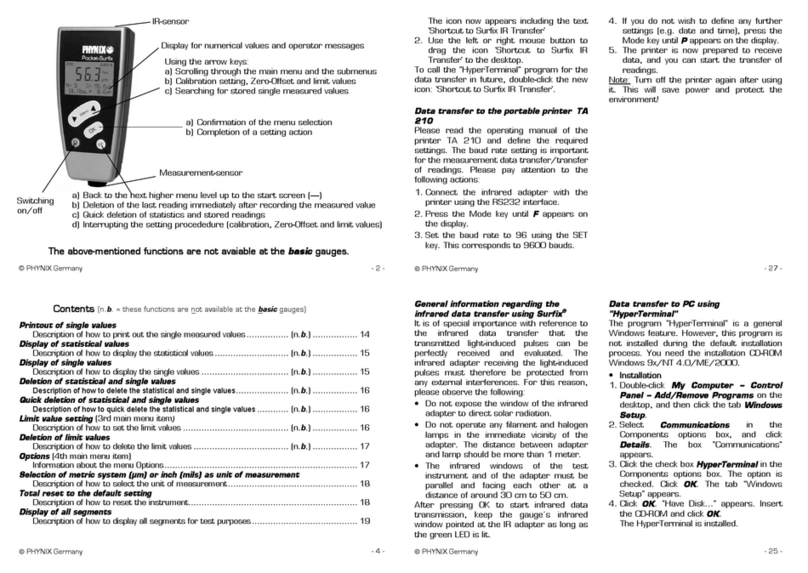

3. Menu structure

There are 6 main menu items: Calibration, Statistics, Measuring mode, Data memory,

Transfer to PC and Options. All other menu items or functions are subordinate to these 6

menu items.

The operation is carried out by means of the two arrow keys and , the confirmation

key and the escape key .The steps to be carried out are displayed on the screen,

e.g. “Place probe on foil standard“. After pressing the confirmation is displayed, e.g.

„Calibration has been set“.

You can find a diagram of the menu structure at the end of this manual. A single look at

this structure is sufficient to recognize the applicable menu items to select a desired

function.

4. Calibration (1st menu item)

This section informs you about the different calibration modes and the application cases

that they are especially suitable for. To meet the demands of coating thickness

measurement tasks the gauge has to be checked by means of the standards included in

the supply package before the measurement.

Surfix® Pro X has two operating modes: in the Direct mode you can directly measure

without any further user interaction. Readings, calibration values and settings are stored

consecutively in the direct memory, in case of a FN combination probe either in the F

memory or in the N memory. The differentiation between F memory and N memory

means also that e.g. setting of limit values has to be done in both measuring modes. The

direct mode enables very quick measurements; but all readings are within one single

memory (FN probe: two single memories).