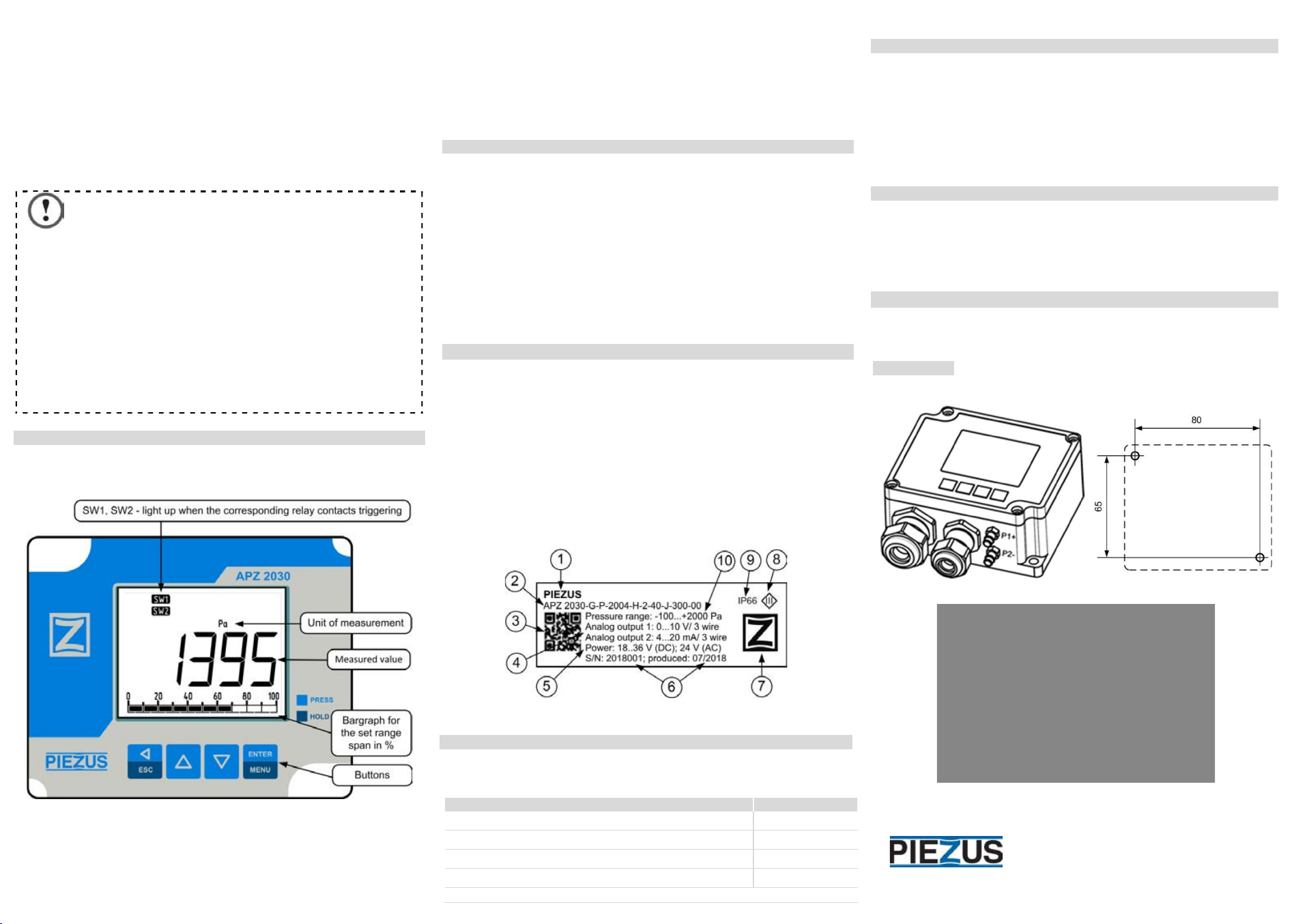

APZ 2030

Operation Manual

2.1.2 You can set spans for the device with control buttons found on the front

panel. See Table 1 for basic and optional spans.

Table 1 - Spans

-200…+200

0…100

0…200

0…500

0…100

0…200

0…500

0…1000

0…1500

0…2000

0…3000

0…5000

2.1.3 See Table 2 for output signal parameters.

Table 2 - Output parameters

Parameter Value (properties)

Number of measuring channels

Voltage output

(3-wire) / load resistance

0...10 V / ≥10 kOhm

Current output

(3-wire) / load resistance

4...20 mA / ≤ 500 Ohm

2 (independent)

Type of mechanical switch contact

Max switching voltage 250 V (AC) / 30 V (DC)

Max switching current (contact type)

5 A (NO)/3 A (NC)

Switched signals (active load):

- DC, voltage of 30 V

- AC, voltage of 250 V

5 A (NO)/3 A (NC)

5 A (NO)/3 A (NC)

Tripping threshold (configurable), % of span

0…100

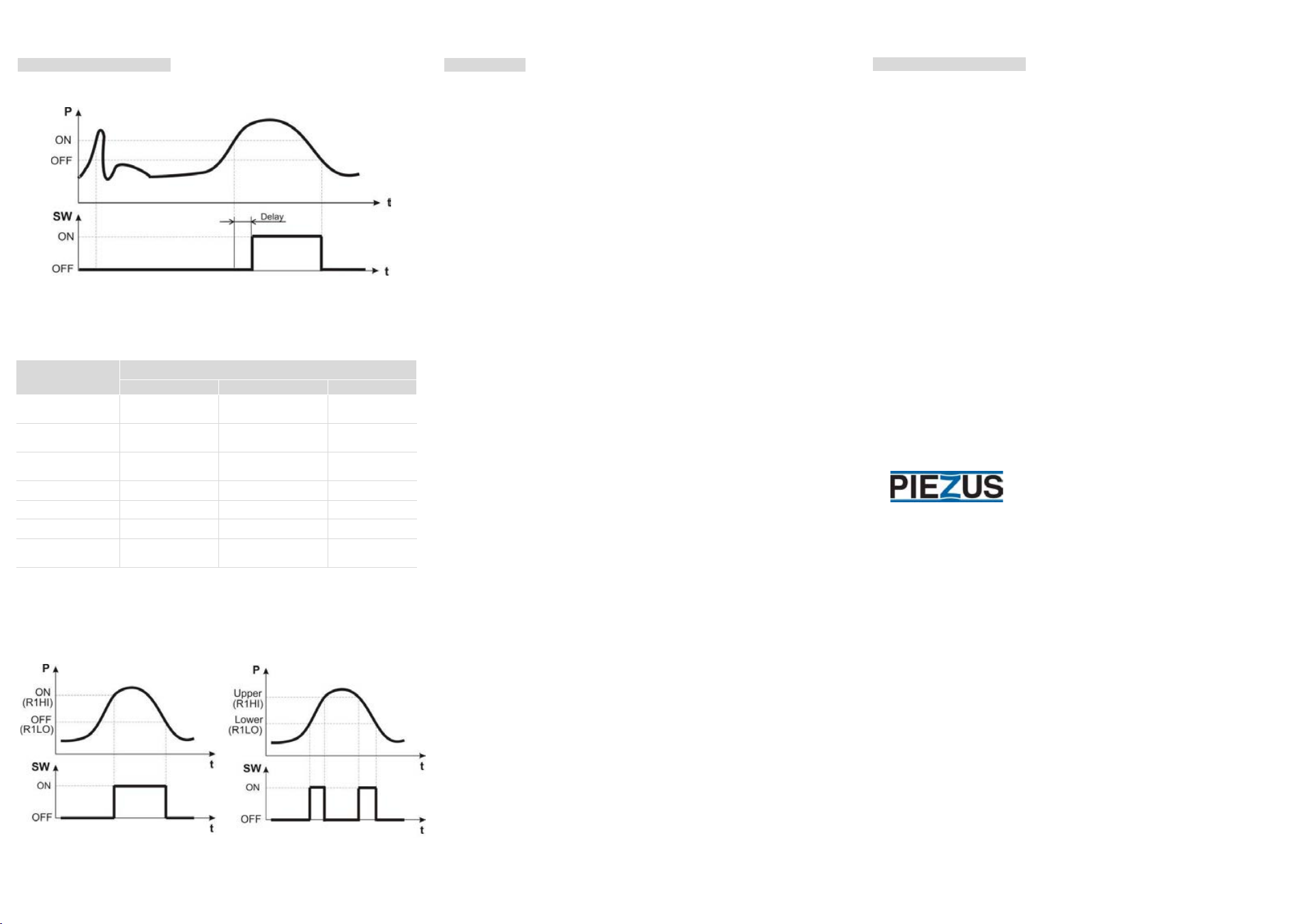

Switch operating modes (configurable)

2.1.4. The device has a display, see Table 3 for its specifications.

Table 3 - Display specifications

Name Value

Range of displayed values

Primary / secondary line height

Displayed accuracy 0.1% of span ± low-

order digit as % of span

Readings display time, max

2.1.5 DC power supply voltage ranges from 18 to 36 V (rated - 24 V), AC - 24

V ± 10%.

2.1.6 Consumed current/power, max - 100 mA/3.6 W.

2.1.7 Dimensions, max - 106 × 91 × 44 mm (Supplement A).

2.1.8 Weight, max - 0.25 kg.

2.1.9 Housing ingress protection (GOST 14254) - IP66.

2.2. Operating conditions:

2.2.1 The device was designed to operate in the following conditions:

- enclosed explosion-proof spaces free from aggressive vapors and gases;

- ambient temperature from -10 to +50 °С;

- medium temperature from -5 to + 65 °C;

- atmospheric pressure from 84 to 106.7 kPa.

2.2.2 Medium: air, non-flammable and non-aggressive gases.

2.2.3 Resistance to atmospheric pressure puts the device in group R1 under

GOST R 52931 (max height above sea level - 1000 m).

2.2.4 Resistance to mechanical attack puts the device in group N2 under

GOST R 52931.

2.3 Operating limitations:

- medium should be free from crystallizable impurities, contaminations and

dust;

- medium should be free from flammable and aggressive gases and liquids.

3 Safety precautions

3.1 The electric shock hazard class of the device is III (no dangerous voltage);

see GOST 12.2.007.0 for full classification.

3.2 Take measures to prevent moisture from getting into the housing.

3.3 Only qualified specialists that have read and understood this manual are

allowed to mount, connect, adjust, do maintenance on the device.

4Mounting and use

4.1 Mount the device onto a vertical surface through two Ø5 mm holes (see

Supplement A). Make sure its pressure port and cable glands point downwards

(to allow condensate draining).

4.2 See Figure 1 for circuits connection diagram (connected inside the

housing via cable glands).

Figure 1 - Connection diagram; P1, P2 - inlet medium pressure, P1 (+) for

higher pressure, P2 (-) for lower pressure.

This manual covers mounting and operation of APZ 2030 differential pressure

transmitter (hereinafter referred to as "transmitter" or "device"); it contains

technical data, description of design and other information necessary for

proper application and maintenance of the device.

See datasheets at http://piezus.ru for complete specifications.

Production regulated by TOR 4212-000-7722857693–2015.

Terms and abbreviations used in the manual:

Span – measurement range; NC - normally closed (NC contact);

NO - normally open (NO contact); SW1, SW2 - switch contacts.

1 Purpose of the device

1.1 APZ 2030 differential pressure transmitter finds application in monitoring,

protection, alarm and control systems in heat and power installations, air

conditioning systems, various industrial environments and public utilities.

1.2 The device:

- proportionally and linearly converts measured differential pressure and

outputs normalized voltage (0 ... 10 V) and current (4 ... 20 mA) signals;

- compares current pressure value to the preset thresholds and outputs two

switching signals when the monitored parameter crosses those thresholds (as

prescribed by the selected operation algorithm, hysteresis or window);

- shows current pressure value (in selected units) and discrete outputs status

on the integrated digital display. Display and buttons allow quick

reconfiguration of the device and eliminate the need to unmount it for that

purpose.

1.3 Applications - heating, ventilation and air conditioning systems (HVAC/R):

- monitoring of flows in ventilation ducts;

- control of exhaust and discharge fans in air ducts;

- differential pressure control in filters

- air pressure control in clean rooms;

- air supply and fire flaps control;

- overheating protection for ventilation heaters;

- HVAC systems emergency control.

2 Technical specifications

2.1 General technical data

2.1.1 See transmitter's passport and label (sticker) for basic span and accuracy

info.

www.piezus.ru

PRESSURE TRANSMITTER