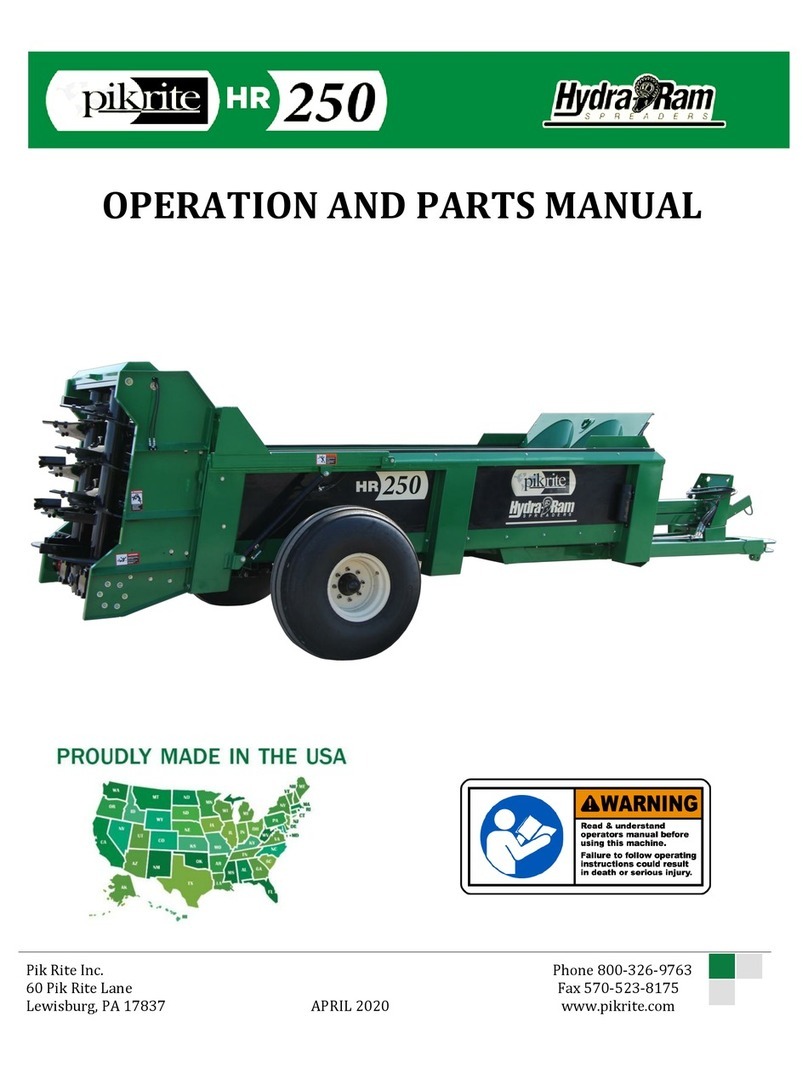

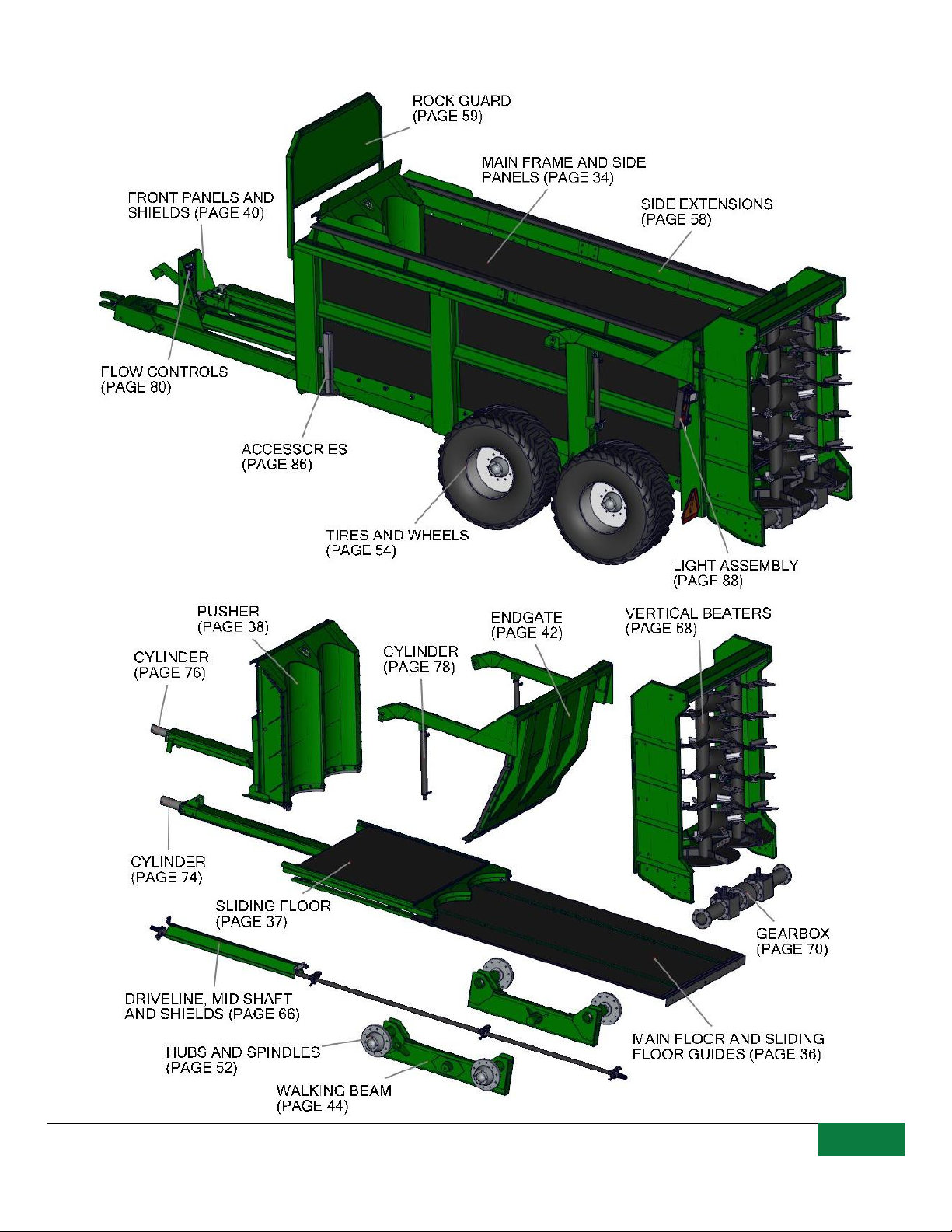

Pik Rite Inc. | HR550 Manure Spreader 2020 |

OPERATION MANUAL INTRODUCTION

TO THE NEW OPERATOR OR OWNER

Since 1986 Pik Rite equipment has been developed by people who work as hard as you do in the

fields, on the farm and on site. Our goal is to deliver products that get the job done with the most

efficient results. If you want tough, dependable people and products you can count on, we’ve got

your back.

This manual is provided to all our customers of newly manufactured manure spreaders to create

an awareness of all maintenance expectations and dangers that may be encountered when

owning this equipment. This manual should be kept for all future references. Please review these

operating instructions carefully, then sign and date the last page of this document and return it to

Pik Rite Inc. for processing. This will activate your warranty and verify that you have read and

understand the following operating instructions and warnings. In the event you have questions

or encounter other applications not discussed in this manual, please call before proceeding.

Congratulations and Thank You for choosing a quality manure spreader manufactured by Pik

Rite Inc. We believe you’ll be very satisfied with the purchase, and we appreciate your patronage.

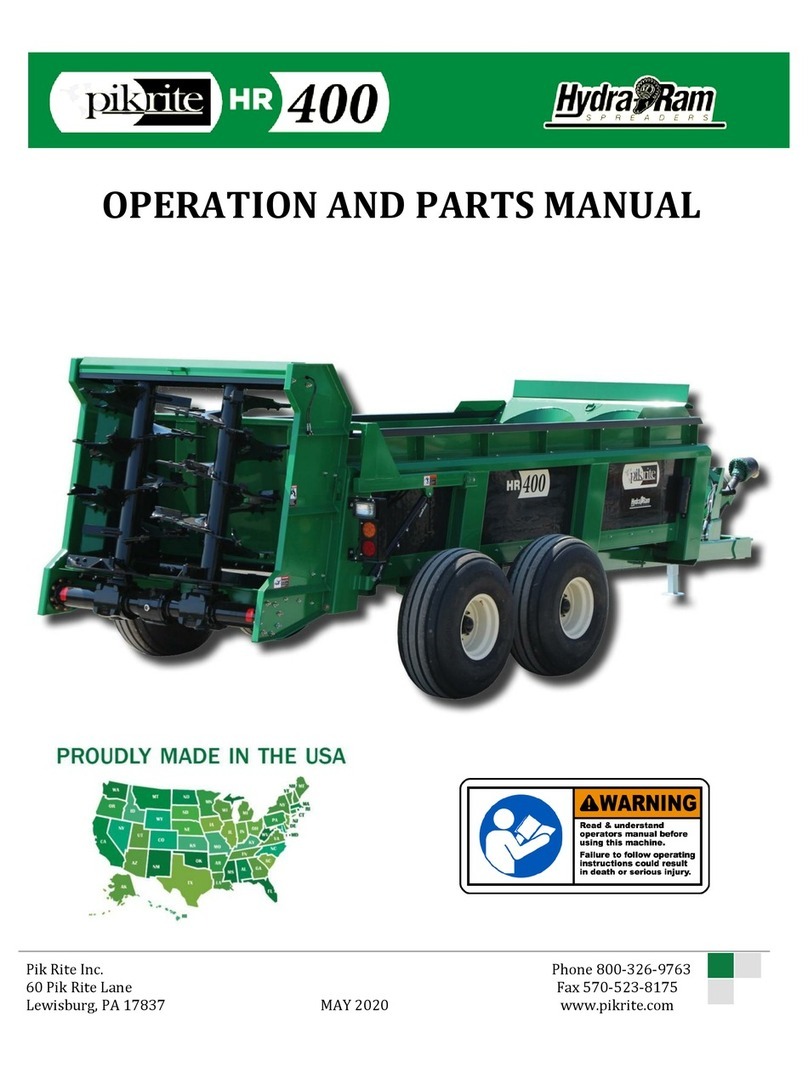

PRINCIPLES OF OPERATION

The legacy of the 2-stage hydraulic push began with the John Deere Hydra-Push spreaders. Pik

Rite continues the tradition with the Hydra-Ram series, which are designed to efficiently and

uniformly spread manure. Equipped with a double hydraulic cylinder these spreaders also have a

sliding floor. Each Hydra-Ram spreader is built to withstand the demands of farm life. All side

and floor panels are constructed with a laminated poly covered finish for maximum strength and

durability.

Less Compaction –This line of tough machines uses both a sliding floor and a moving front panel

to deliver the material to the beaters. The sliding floor is pushed back first, using an engineered

hydraulic cylinder. When fully extended, the front panel moves back to unload the box

completely.

Less Maintenance –The Hydra-Ram is engineered to get the job done with fewer moving parts.

This design efficiency extends the life of the spreader while requiring less maintenance and

down-time than other manufacturer’s equipment. Auger systems tend to compact the material

into clumps, causing uneven distribution and increased wear on the beater system. The 2-stage

hydraulic push technology greatly reduces compaction and provides optimal clean-out.

Less Time, Spread Faster –The Hydra-Ram 2-stage push system delivers the material to the

beaters at an even and controlled speed. Manual and/or electric over hydraulic flow controls

allow you to unload the material faster than auger or side sling machines.