Trynex International SnowEx SL-80 Owner's manual

CUSTOMER COPY

Madison Heights, Michigan 48071

800-725-8377

www.turfexproducts.com

Owner / Operator’s Manual

SL-80

Serial # PB-200036 and higher

SL-80SS

Serial # PC-200048 and higher

This Manual Must Be Read Before Operating The Equipment

© TrynEx International 2013

(REV B) F50775

© TrynEx International 2013 (REV B) F507752

Table of Contents

General Information ...................................................................................................................................................................................... 3

Introduction ................................................................................................................................................................................................. 4

Safety .......................................................................................................................................................................................................... 5

Operational Safety Information .................................................................................................................................................................. 6-8

Sprayer Operation ................................................................................................................................................................................... 9-10

Electrical Schematic .................................................................................................................................................................................. 10

Troubleshooting ......................................................................................................................................................................................... 11

Maintenance................................................................................................................................................................................................ 11

Warranty .................................................................................................................................................................................................... 12

Key to Parts ............................................................................................................................................................................................... 13

Handle Assembly Parts Breakdown

Model # SL-80 ....................................................................................................................................................................... 14-15

Model # SL-80SS ................................................................................................................................................................... 16-17

Tank Assembly Parts Breakdown

Model # SL-80 ....................................................................................................................................................................... 18-19

Model # SL-80SS ................................................................................................................................................................... 20-21

Pump Assembly Parts Breakdown

Model # SL-80 ....................................................................................................................................................................... 22-23

Model # SL-80SS ................................................................................................................................................................... 24-25

Notes ................................................................................................................................................................................................... 26-27

Have a question or need assistance?

SnowEx Customer Care

(800) 725-8377

or (248) 586-3500

Monday through Friday 8:00 AM to 4:30 PM EST

Fax: (248) 691-8378

E-Mail: customercare@trynexfactory.com

Website: www.snowexproducts.com

© TrynEx International 2013 (REV B) F50775 3

General Information

CONGRATULATIONS!

The sprayer you have purchased is an example of snow and ice control technology at its nest! Your spreader’s self-contained design is a

trademark of all SnowEx products. Here’s why…

SIMPLICITY: Fewer moving parts manufactured of higher quality means minimal maintenance for your SnowEx spreader.

RELIABILITY: High impact linear low density polyethylene hopper. Custom-engineered powder-coated frame. Found only on SnowEx Products.

VERSATILITY: Multi-use capability allows spreading of a variety of materials for snow and ice control.

WARRANTY: Best in the industry, hands down! 2 years standard and now 5 year extended (optional).

The benets you are about to recognize are that of time, money and effort.

We welcome you to the world of SnowEx Performance.

Registration

Record the following information in this manual for quick reference.

Spreader Model Number

Spreader Serial Number

Date of Purchase

Dealer Where Purchased

When ordering Parts, the above information is necessary. This will help to see that

you receive the correct parts.

At the right is a diagram of the ID tag. This tag on the spreader is located on the

frame.

Please ll out the warranty card with all the necessary information to validate it.

This will also give us a record so that any safety or service information can be

communicated to you.

© Trynex International 2009 L1102

5 — 4

General Information

CONGRATULATIONS!

The spreader you have purchased is an example of snow and ice control technology at its Your spreader’s

self-contained

design is a trademark of all Snowex products. Here’s why...

SIMPLICITY: Fewer moving parts manufactured of higher quality means minimal maintenance for your SnowEx spreader.

RELIABILITY:

High impact linear low density polyethelyne hopper, state-of-the-art electronic dual variable speed control, custom

engineered

powder coated frame, maximum torque 12 volt motor coupled to a custom engineered transmission; found only

on SnowEx products.

VERSATILITY:

Multi-use capabilities allows spreading of a variety of materials for snow and ice control.

The you are about to recognize are that of time, money and .

We welcome you to the world of Snowex Performance.

Registration

Record the following information in this manual for quick reference.

Spreader Model Number _____________________________________________________________________________________

Spreader Serial Number________________________________ Controller Serial Number _______________________________

Date of Purchase___________________________________________________________________________________________

Dealer Where Purchased _____________________________________________________________________________________

When ordering parts, the above information is necessary. This will help to

that you receive the correct parts.

At the right is a diagram of the ID tag. This tag on the spreader is located

on the frame.

Please out the warranty card with all the necessary information to validate it. This will also give us a record so that

any safety or service information can be communicated toyou.

WARRANTY:

Best in the industry, hands down! 2 years standard and now 5 year extended (optional).

PB-200036

PC-200048

© TrynEx International 2013 (REV B) F507754

Introduction

This manual has been designed for your help. It will assist you and instruct you on the proper set-up, installation and use of this spreader.

Refer to the table of contents for an outline of this manual.

We require that you read and understand the contents of this manual completely (especially all safety information) before attempting any

procedure contained herein.

THIS SIGN SHOULD ALERT YOU:

The Society of Automotive Engineers has adopted this SAFETY ALERT SYMBOL to pinpoint characteristics

that, if NOT carefully followed, can create a safety hazard. When you see this symbol in this manual or on the

machine itself, BE ALERT! Your personal safety and the safety of others is involved.

Dened below are the SAFETY ALERT messages and how they will appear in this manual:

(RED)

Information that, if not carefully followed,

can cause death!

(ORANGE)

Information that, if not carefully followed,

can cause serious personal injury or death!

(YELLOW)

Information that, if not carefully followed,

can cause minor injury or damage to equipment

© TrynEx International 2013 (REV B) F50775 5

Safety

Before attempting any procedure in this book, these safety instructions must be read and understood by all workers who have any part in the

preparation or use of this equipment.

For your safety warning and information decals have been placed on this product to remind the operator of safety precautions . If anything

happens to mark or destroy the decals, please request new ones from SnowEx.

Remember, most accidents are preventable and caused by human error. Exercising of care and precautions

must be observed to prevent the possibility of injury to operator or others!

Never operate equipment when under the inuence of alcohol, drugs, or medications that might alter your

judgment and/or reaction time.

Before working with the spreader, secure all loose tting clothing and unrestrained hair.

Always wear safety glasses with side shields when servicing spreader. Failure to do this could result in

serious injury to the eyes.

Never attempt to lift a unit with liquid in it.

Never allow children to operate or climb on equipment.

Always check areas to be spread to be sure no hazardous conditions or substances are in the area.

Always inspect unit for defects: broken, worn or bent parts, weakened areas on spreader.

Remember it is the owner’s responsibility to communicate information on safe usage and proper

maintenance of all equipment.

Always make sure personnel are clear of areas of danger when using equipment.

Never weld or grind on equipment without having a re extinguisher available.

© TrynEx International 2013 (REV B) F507756

Operational Safety Information

Summary of Important Safety Information

Chemical accident procedures

Immediate response is necessary in the event of sprayer leaks, bodily chemical contact, poisoning, or spills.

See instructions below:

Sprayer Leak If the sprayer develops a leak, immediately stop spraying. Turn off power to the sprayer

and follow directions below, as applicable.

Bodily chemical Personal contamination can occur when chemicals splash, spill, or spray directly

contact onto a person.

1. Immediately follow First Aid instructions on chemical label.

General procedures can include:

a)Eyes–immediatelyushwithwater.

b) Skin – wash all contaminated skin surfaces with soap and water.

c) Clothing – remove contaminated clothing. Dispose of heavily contaminated

clothing per chemical label instructions.

2. Seek medical advice if instructed on the label or the victim experiences symptoms of

harmful effects. Bring the chemical label for reference.

Poisoning by In case of poisoning from ingestion or inhalation

ingestion or If the victim has collapsed or is not breathing, call 911. Otherwise:

inhalation 1. If you are the victim, immediately seek assistance from nearby personnel, because you

may become incapacitated.

2. Immediately follow _rst aid instructions on chemical label.

3. Call a poison control center for further advice. In the U.S., call 1-800-222-1222. Have

the chemical label available for reference.

Chemical spills Chemical spills must quickly be contained and properly cleaned up.

Refer to the chemical label for any specifc clean-up instructions.

General procedures include:

1. Controlling the spill by stopping the source of the spill.

2. Containing the spill so that it does not spread and get into water sources.

3. Cleaning up the spill immediately.

4. Seeking additional advice from:

- Chemical manufacturer. See chemical label for contact information.

- State pesticide regulatory agency. In the U.S., call the National Pesticide Info. Ctr.

at 800-858-7378 for assistance in contacting your state’s agency.

© TrynEx International 2013 (REV B) F50775 7

Operational Safety Information

Summary of Important Safety Information

Listed below is a summary of safety information of particular importance.

See individual sections of this owner’s manual for more details.

DURING ASSEMBLY

Check and test completed assembly as directed in this manual. Serious injury could result from chemical

leaks if sprayer is improperly assembled.

DO NOT MODIFY SPRAYER DESIGN

DURING OPERATION

• Read and follow each chemical label’s instructions and warnings.

• Avoid inhaling, ingesting, or coming into contact with any chemicals.

• Know applicable licensing and regulatory requirements for the chemical you plan to use.

• Know emergency procedures before handling chemicals. Carefully review “Chemical Accident Procedures” listed below and later in this

manual Also see First Aid instructions on the chemical label.

• Wear protective clothing, eye protection, and chemical resistant gloves when lling, using and cleaning the sprayer. Wear additional

protective gear, such as facemask or apron, as recommended on the chemical label.

• Exercise extra caution around children and pets. Keep sprayer and spray materials away from them at all times.

• Do not mix or pour chemicals in an enclosed, unventilated area.

• Do not use ammable or corrosive chemicals in the sprayer.

• Flush the sprayer before switching chemicals in order to prevent dangerous chemical interactions.

BEFORE SPRAYING

• Inspect and prepare sprayer before each use as directed in this manual.

• Do not start sprayer until ready to spray in order to avoid unintentional spray release.

• Wear additional personal protective equipment if you will be spraying overhead.

You will be exposed to much more chemical fallout in these applications. Wear chemical resistant head and neck protection, full face

mask or half-face mask with sealed goggles, and consider using a respirator.

• Do not spray when wind speed exceeds four miles per hour in order to minimize spray drift.

• Keep sprayer and spray materials away from children and pets.

• Do not allow anyone younger than 16 to operate sprayer.

© TrynEx International 2013 (REV B) F507758

Operational Safety Information

Summary of Important Safety Information

DURING SPRAYING

• Do not over-apply. Apply at rate recommended by chemical manufacturer.

• Do not eat, drink, smoke, rub your eyes or touch your bare skin while handling chemicals and spraying.

• Never point the spray gun at people or animals.

• Donotspraynearopenamesorsourcesofheat.

• Alwaysholdthespraygunrmlywhenusingittosprayathigherpressuresinordertopreventgunfromwhipping.Keepgood

footing and balance at all times.

• Exercise extra caution when spraying near areas accessible to children and pets.

• Clean up spills immediately per instructions on the chemical label.

• Turn off sprayer, and relieve system pressure before leaving sprayer unattended.

• See the Troubleshooting section of this manual before attempting any repairs. Wear personal protective equipment and follow

safety instructions.

AFTER SPRAYING

• Clean sprayer immediately after use according to the directions provided in this manual.

• Decontaminate yourself after you are done spraying and have cleaned the sprayer. Wash all exposed areas of the body with soap

and water, and remove and launder clothing.

• Dispose or store remaining chemicals in secure storage with correctly marked container.

TRANSPORTING SAFETY

• Read safety instructions in your vehicle manual with regard to carrying heavy cargo loads.

• Do not allow drivers younger than 16 to drive the vehicle with the sprayer attached.

• Make sure sprayer is securely attached to vehicle.

• Exercise caution in vehicle handling when driving with sprayer to avoid loss of control or rollover.

oKeepspeedtoaminimumsoyoucanmaintaincontrol.Reducespeedpriortoturns.

o Allow for more distance to stop.

o Avoid any sudden steering maneuvers, starts, or stops that could create liquid sloshing in the sprayer and instability.

• Slow down and exercise caution on sloped or uneven terrain.

• Be aware that visibility may be reduced when making turns or backing up.

• Turn off sprayer before leaving unattended.

• Do not attempt to lift with liquid in sprayer

© TrynEx International 2013 (REV B) F50775 9

1) Fill sprayer with material through top hole.

Caution: Always use gloves and safety goggles when lling sprayer.

2) Place valve in position for desired use.

3) If using spray wand never point at objects (ie: humans, vehicles etc.)

4) If using spray nozzle keep away from objects (ie: humans, vehicles etc.) at least 10 feet.

5) When not moving or spraying place switch in off position.

Sprayer Operation

Model # SL-80/SL-80SS

© TrynEx International 2013 (REV B) F5077510

Sprayer Operation & Electrial Schematic

Model # SL-80/SL-80SS

1) Charge battery after each use. Disconnect harness and connect to battery charger as shown below. Then plug charger into 110v outlet.

Green to Pos A

Black to Pos B

White to Pos C

Green

White

F50016

F50106

F50107

F50078

© TrynEx International 2013 (REV B) F50775 11

Troubleshooting & Maintenance

Model # SL-80/SL-80SS

Whenever service is necessary, your local SnowEx Dealer knows your Sprayer best. Take your Sprayer to your local dealer for any

maintenance or service needs on your unit. If this is not possible, the Troubleshooting Guide below may assist you in identifying the problem.

Warning: First read all warning instructions and safety messages before servicing your Sprayer.

Preliminary Checks

• Be sure all electrical connections are tight and clean.

• Be sure nothing is obstructing the nozzles.

PROBLEM POSSIBLE CAUSE SOLUTION

Pump doesn’t run. Loose electrical connections. Check all connections.

Pump Seized. Replace pump.

Electrical short. Check for bare wires.

Liquid not spraying. Empty tank. Fill tank.

Pump not running. Refer to Problem 1

Obstructed nozzle. Remove and clean.

Maintenance:

1) Grease Axle zerks after every 20 hours of use.

2) When putting into storage for season drain tank and hose lines and ush pump.

© TrynEx International 2013 (REV B) F5077512

Warranty

L1185 © Trynex International 2009

5 — 38

Warranty

Limited Warranty

Snowex products are warranted for a period of two years from the date of purchase against

defects in material or workmanship under normal use and service, subject to limitations detailed

below. Warranty period of two years begins on the date of purchase by the original retail user.

TheWARRANTY REGISTRATION CARD must be returned to the manufacturer for this warranty

to become eective. This warranty applies to the original retail purchaser only. This warranty does

not cover damages caused by improper installation, misuse, lack of proper maintenance, alterations

or repairs made by anyone other than authorized Snowex dealers or Snowex personnel. Due to the

corrosive properties of the materials dispensed by spreaders, Trynex does not warrant against

damage caused by corrosion. Warranty claims by the user must be made to the dealer from where

the product was purchased, unless otherwise authorized by Snowex. Snowex reserves the right to

determine if any part is defective and to repair or replace such parts as it elects. This warranty does

not cover shipping costs of defective parts to or from the dealer.

LIMITATION OF LIABILITY

Neither Snowex, nor any company aliated with it, makes any warranties, representations for

promise as to the performance or quality other than what is herein contained. The liability of Snowex

to the purchaser for damages arising out of the manufacture, sale, delivery, use or resale of this

spreader shall be limited to and shall not exceed the costs of repair or replacement of defective

parts. Snowex shall not be liable for loss of use, inconvenience or any other incidental, indirect or

consequential damages, so the above limitations on incidental or consequential damages may not

apply to you.

NO DEALER HAS AUTHORITY TO MAKE ANY REPRESENTATION OR PROMISE ON BEHALF OF

SNOWEX, OR TO ALTER OR MODIFY THE TERMS OR LIMITATIONS OF THIS

WARRANTY IN ANY WAY.

© TrynEx International 2013 (REV B) F50775 13

Key to Parts

D5377 Hose Barb | 1/2” Male Thread X 3/8” 90°

D5381 Hose Barb | 1/4” Male Thread X 3/8”

D5384 Decal | Quality Made In The USA

D5387 Decal | Serial Number | SL-80

D5388 Decal | Serial Number | SL-80SS

D5901 Hopper Frame | SL-80

D5904 Wheel 13” X 5”

D5906 Frame Stand | SL-80

D5908 Handle | SL-80

D5915 Axle

D5917 Handle Grip

D5919 Cotter Pin | 2” Stainless

D5923 Wheel Bushing

D5943 Bolt | 1/4”-20 X 2-1/4” Hex

D5994 Grease Fitting

D6024 Shaft Collar

D6131 Bolt | 1/4”-20 X 1/2” Serr. Flange

D6132 Bolt | 1/4”-20 X 3/4” Serr. Flange

D6172 Bolt | #10-32 X 5/8” Serr. Flange

D6822 Cable Tie | Push Mount

D6854 Bolt | 1/4”-20 X 1” Serr. Flange

D6988 Hose | 3/8”

F50000 Battery Bracket | SL-80

F50001 Wand Bracket | SL-80

F50002 Battery

F50003 Hose Guide | SL-80

F50004 Pump Enclosure | SL-80

F50005 Pump

F50006 Pump Enclosure Cover | SL-80

F50007 Inside Nozzle Body Bracket | SL-80

F50008 Coil Hose

F50009 Tank

F50011 Panel Mount Valve

F50012 Outside Nozzle Body Bracket

F50013 Hose Barb | 1/4” Male Thread X 3/8” 90°

F50014 Nozzle | Push Sprayer

F50015 Nozzle Body

F50016 Harness | Pump

F50019 Battery Bracket | SL-80SS

F50020 Wand Bracket | SL-80SS

F50021 Hose Guide | SL-80SS

F50022 Pump Enclosure | SL-80SS

F50023 Pump Enclosure Cover | SL-80SS

F50024 Inside Nozzle Body Bracket | SL-80SS

F50025 Outside Nozzle Body Bracket | SL-80SS

F50078 Battery Charger

F50079 Decal | On / Off - SL-80

F50080 Decal | Spray / Wand - SL-80

F50106 Harness | Switch

F50107 Switch

F50108 Tank Strainer

F50109 Rubber Grommet

F50111 Reducing Bushing | 3/8” X 1/4”

F50112 Bolt | 5/16”-18 X 1-1/4” Hex

F50145 Hose Clamp | 3/8”

F50651 Pipe Plug | 1/2”

F50775 Owner’s Manual

T15016 Nut | 1/4”-20 Nylox

T15018 Nut | 5/16”-18 Nylox

T20307 Spot Spray Wand

T20317 Decal | Caution - Wear Safety Goggles

T30151 Hopper Frame | SL-80SS

T30152 Frame Stand | SL-80SS

T30153 Handle | SL-80SS

© TrynEx International 2013 (REV B) F5077514

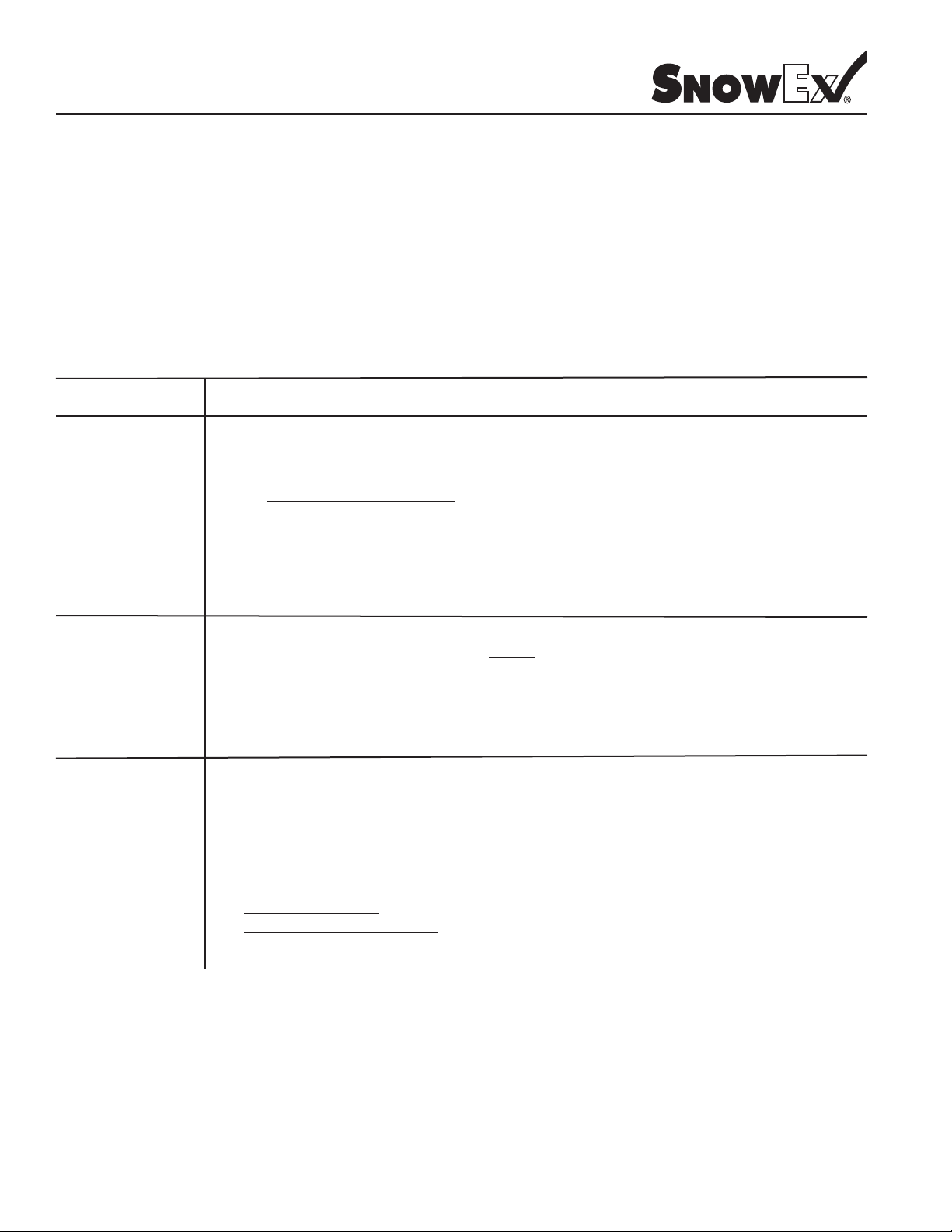

Handle Assembly Parts Breakdown

Model # SL-80

6

7

2

13

11

10

1

5

4

12

9

8

3

© TrynEx International 2013 (REV B) F50775 15

Handle Assembly Parts Breakdown

Model # SL-80

BOM ID

Description

Qty

1

D5908

1

2

D5917

2

3

D6132

1

4

D6406

1

BOM ID

Description

Qty

5

F50001

1

6

F50008

1

7

F50016

1

8

F50106

1

BOM ID

Description

Qty

9

F50107

1

10

F50112

2

11

T15016

1

12

T15018

2

BOM ID

Description

Qty

13

T20307

1

© TrynEx International 2013 (REV B) F5077516

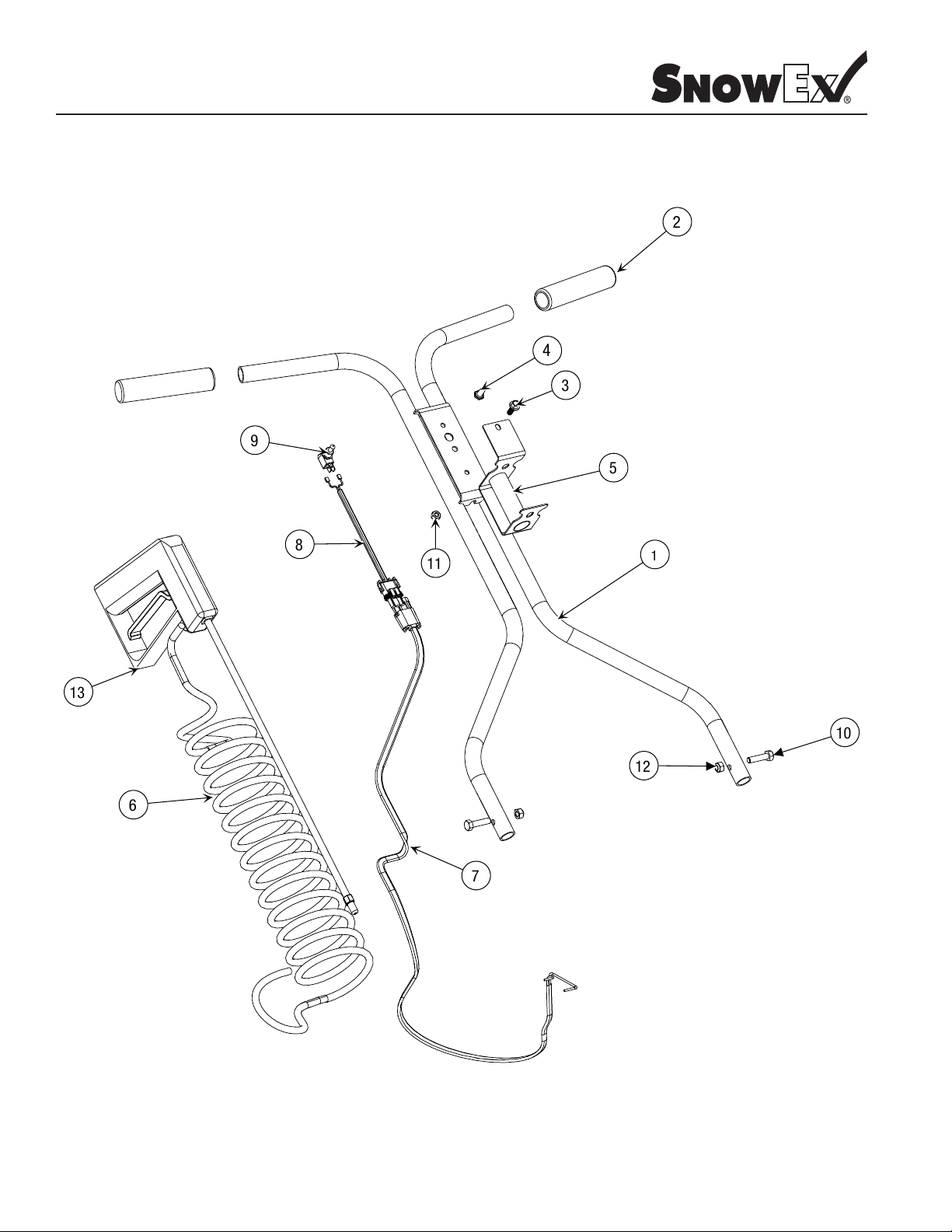

Handle Assembly Parts Breakdown

Model # SL-80SS

6

5

1

12

10

8

7

4

9

3

13

11

2

© TrynEx International 2013 (REV B) F50775 17

Handle Assembly Parts Breakdown

Model # SL-80SS

BOM ID

Description

Qty

1

D5917

2

3

D6406

1

4

F50008

1

5

F50016

1

BOM ID

Description

Qty

6

F50020

1

7

F50106

1

8

F50107

1

9

F50112

2

BOM ID

Description

Qty

10

T15016

1

11

T15018

2

12

T20307

1

13

T30153

1

© TrynEx International 2013 (REV B) F5077518

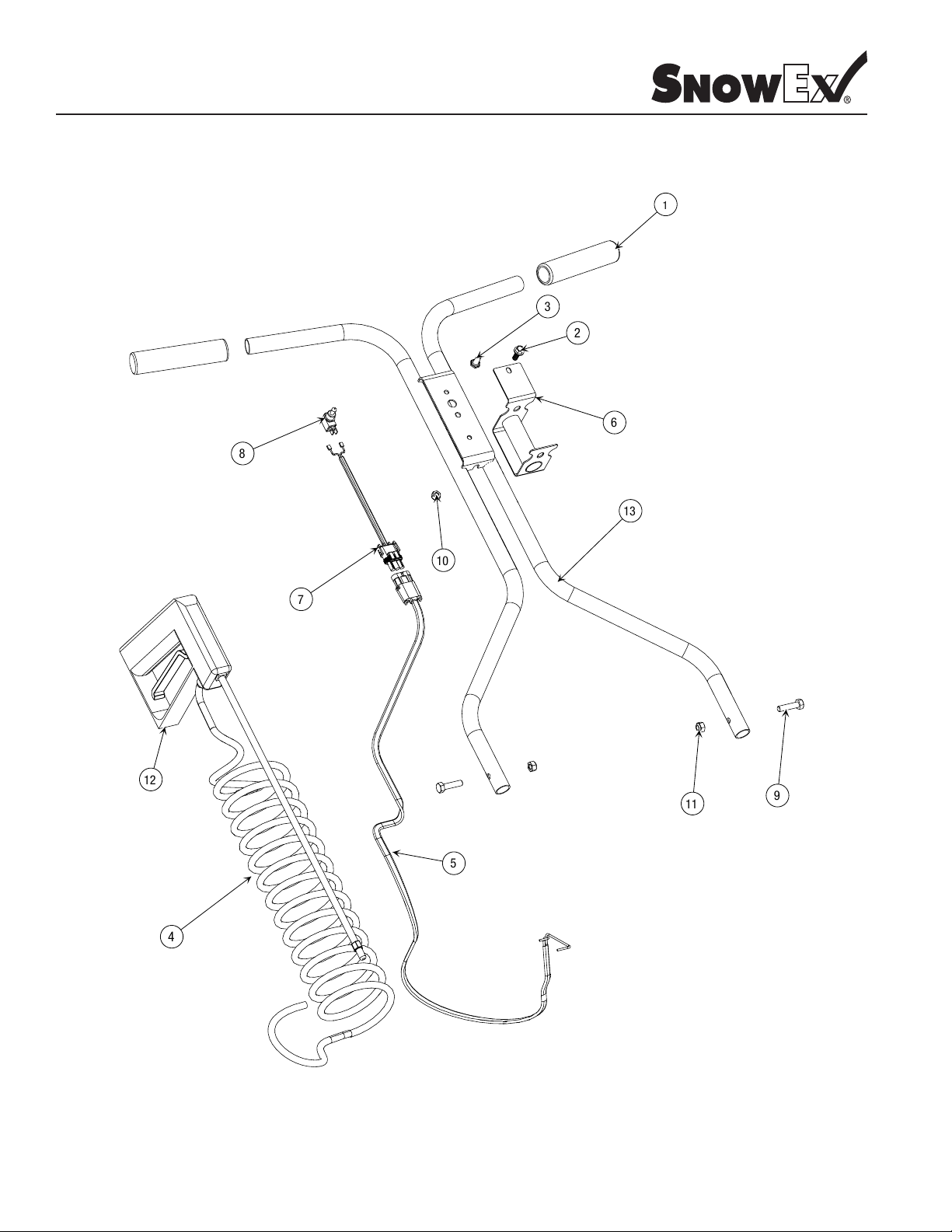

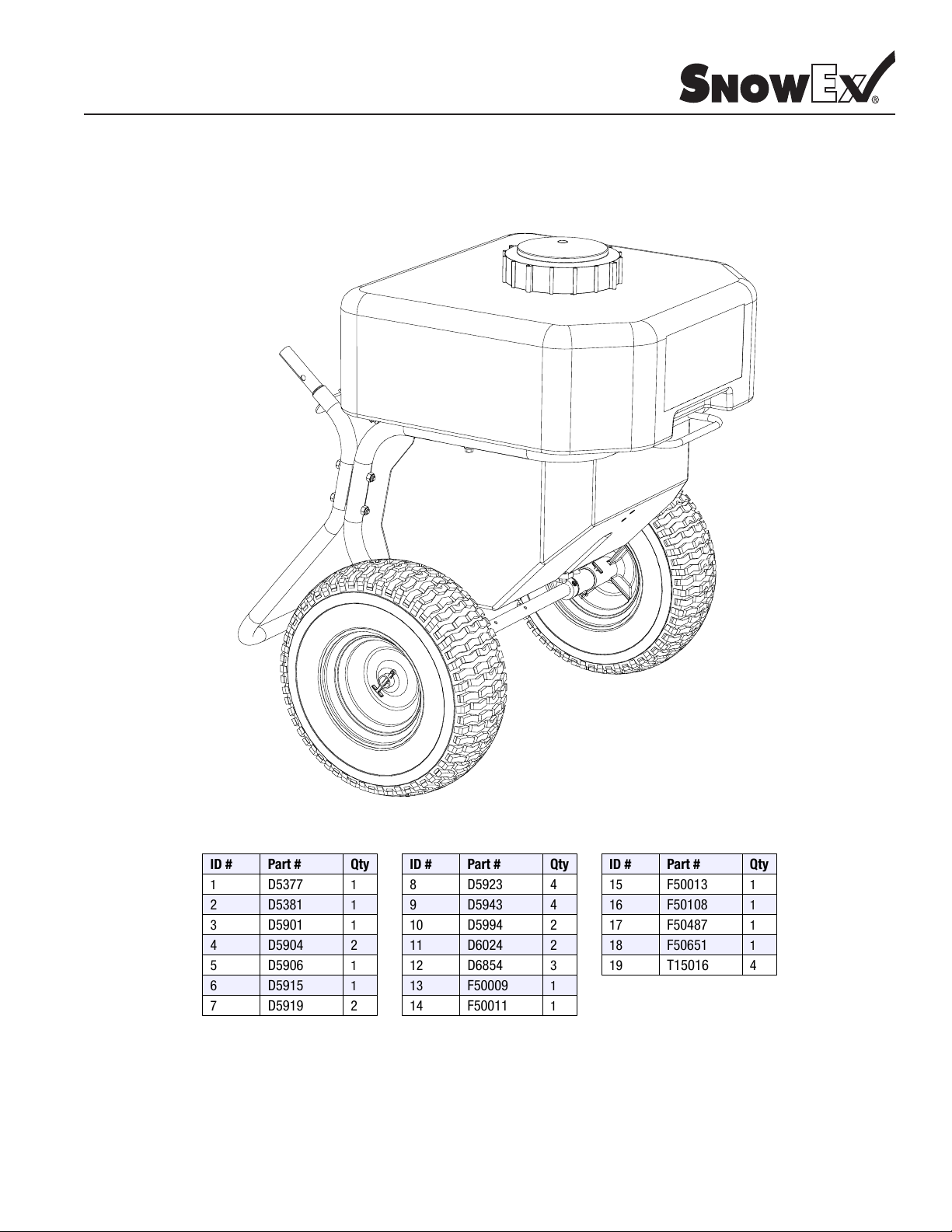

Tank Assembly Parts Breakdown

Model # SL-80

4

15

14

10

7

2

9

6

12

11

5

1

19

8

16

3

18

12

12

7

4

17

13

4

15

14

10

7

2

9

6

12

11

5

1

19

8

16

3

18

12

12

7

4

17

13

© TrynEx International 2013 (REV B) F50775 19

Tank Assembly Parts Breakdown

Model # SL-80

ID #

Part #

Qty

1

D5377

1

2

D5381

1

3

D5901

1

4

D5904

2

5

D5906

1

6

D5915

1

7

D5919

2

ID #

Part #

Qty

8

D5923

4

9

D5943

4

10

D5994

2

11

D6024

2

12

D6854

3

13

F50009

1

14

F50011

1

ID #

Part #

Qty

15

F50013

1

16

F50108

1

17

F50487

1

18

F50651

1

19

T15016

4

© TrynEx International 2013 (REV B) F5077520

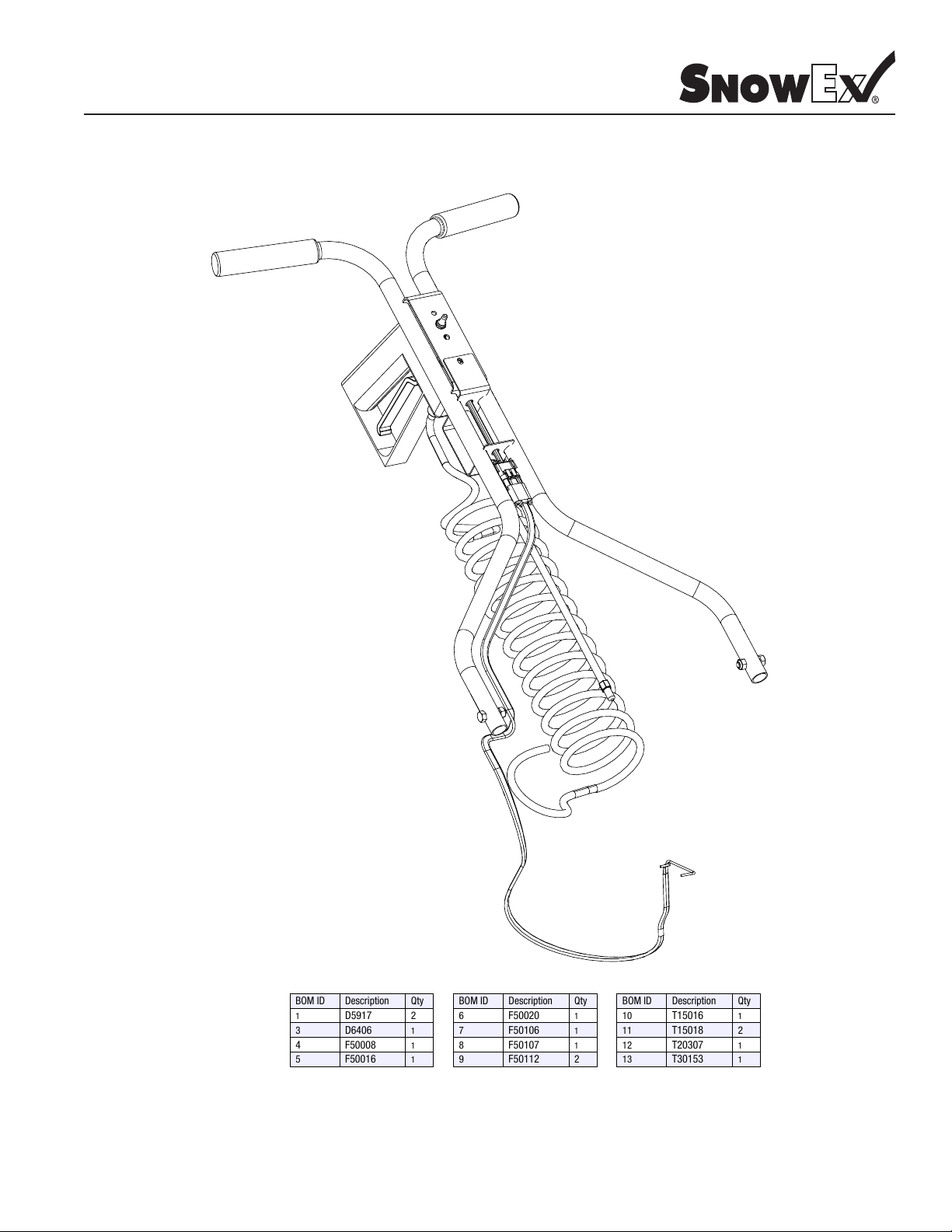

Tank Assembly Parts Breakdown

Model # SL-80SS

5

3

13

8

6

12

2

9

4

7

19

1

14

17

18

3

16

5

10

11

15

5

3

13

8

6

12

2

9

4

7

19

1

14

17

18

3

16

5

10

11

15

This manual suits for next models

1

Table of contents

Other Trynex International Spreader manuals

Trynex International

Trynex International SnowEx SP-125 Owner's manual

Trynex International

Trynex International SnowEx V-Maxx 8500 User manual

Trynex International

Trynex International TurfEx TS45 User manual

Trynex International

Trynex International TurfEx RS7200E User manual

Trynex International

Trynex International SnowEx Pro 575X User manual

Trynex International

Trynex International SnowEx Precision Pro SP-1675 User manual

Trynex International

Trynex International TurfEx TT5000 User manual

Trynex International

Trynex International SnowEx Bulk Pro 1875 User manual