Open/remove the protective covers of the saw blade (see section 4.5.). Use the tensioning star nut to release the wheel and the

blade. In ARG 520 DC, fasten the hardened steel screw in order to release the grip of the blade in the head (see section 4.9.2.). Take

the saw blade off of the moving wheels and push it off the guide heads. Insert the new saw blade in the guide heads. Place it on the

blade wheels (you can control the position of the tensioning wheel by the tensioning star nut). Tension the fitted saw blade. In ARG

520 DC, loosen the contact pressure screw of the saw blade (see Section 4.9.2.). Close/put back the protective covers of the saw

blade and turn on the POWER SWITCH. Turn on the hydraulic unit, switch to the MANUAL MODE and set the minimum saw blade

speed by a SAW BLADE SPEED CONTROLLER. Press the START button of the saw blade to start the saw blade so that it turns

approximately once of the full length. Switch off the POWER SWITCH and secure it against restart. Open/remove the protective

covers of the saw blade to make sure that the saw blade is correctly fitted on the guide heads and correctly installed on the blade

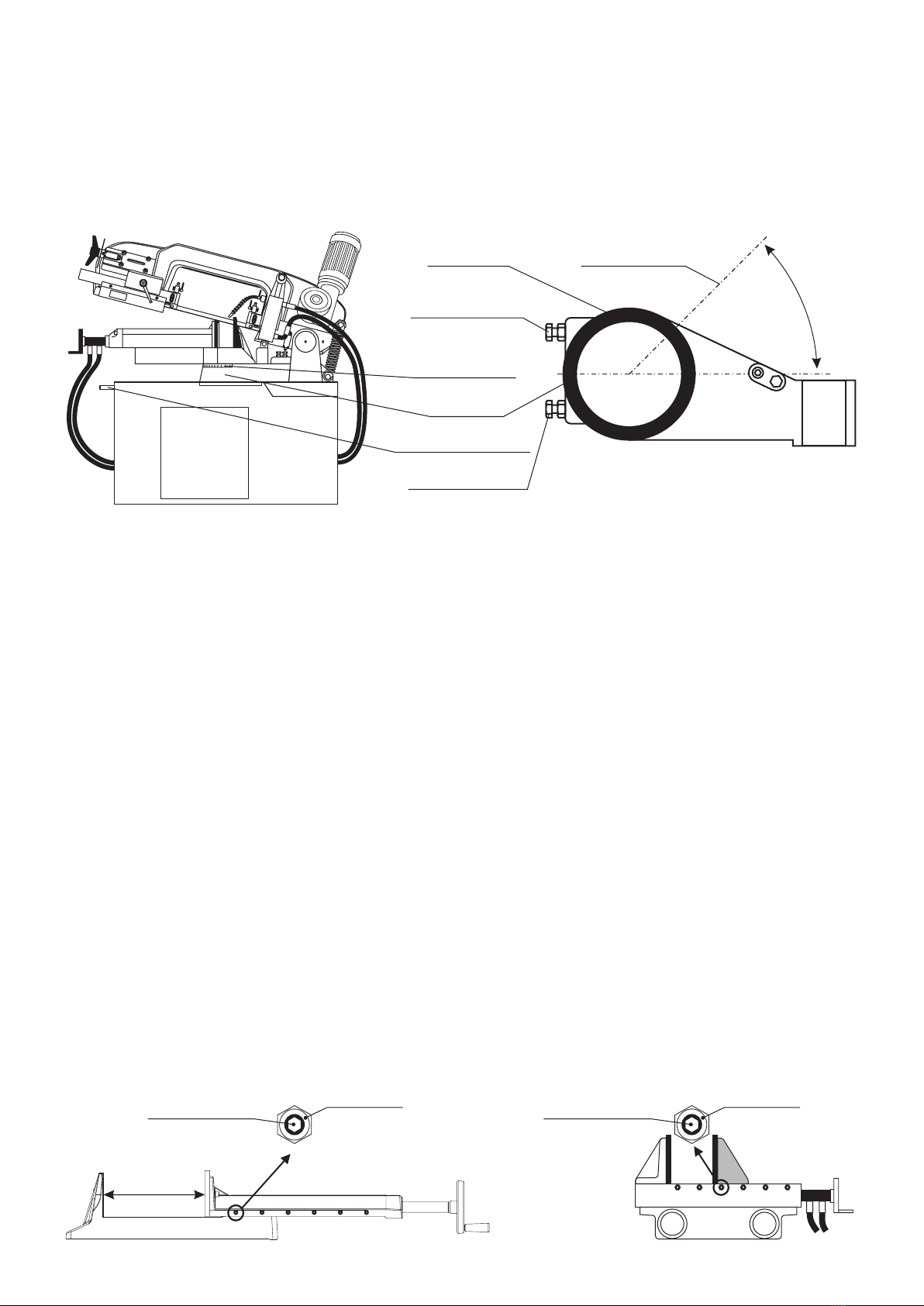

wheels (see figure). The machine is also fitted with a control hole that allows you to check the condition of the saw blade on the

wheels. The hole is covered by a cap.

If the saw blade is not properly set on the wheels, loosen the saw blade a little bit and use the wheel tilting screw to adjust the wheel tilt.

In ARG 520 DC, it is necessary to loosen both fixation screws and, after tilting the wheel, to tighten them again. Tension the saw blade

again and close/put back the protective covers of the saw blade. Turn on the POWER SWITCH and the hydraulic unit. Carry out a

saw blade trial run. Switch off the POWER SWITCH and secure it against restart, open/remove the protective covers of the saw blade

and once again check the placement of the saw blade on the wheels. Repeat the procedure, if required. Close/put back the protective

covers of the saw blade and turn on the POWER SWITCH and the hydraulic unit. Carry out the cutting.

In ARG 520 DC: The spring keeps the saw blade permanently on the moving wheels, even if the hydraulic system is off or the

hydraulic hoses are damaged. WARNING: The spring cannot provide optimum saw blade tension. The limit switch monitors the saw

blade rupture; it turns on when the wheel has reached the end position; thus, the main motor is switched off, which is indicated by the

red lamp on the control board. Caution! While replacing the saw blade, tighten (and after fitting the saw blade loosen again)

the bolts to press down the hardened steel blade guides (ARG 520 DC) before shifting out the saw blade from the guide

heads; see Section 4.9.2.

4.9. Guide Heads Adjustment

4.9.1. Guide heads - adjustment in ARG 260 CF-NC, ARG 300 CF-NC, ARG 300 DCT CF-NC

The correct setting of the bearings and the hardened steel blade guides in the guide heads substantially influences the saw

blade life and the quality of the cut. The eccentrically arranged guide head bearings must be set in such a manner that the saw

blade surface is parallel to the surface of hardened steel blade guides with a minimum play (clearance) between the plates and the

blade.

Guide Head Setting Procedure

Follow the instructions in Section 4.5. in order to tilt/remove the protective covers.Set the movable guide head, so that the distance

between the guide heads is approximately 20 cm. Disconnect the inlet hoses from the coolant valve. Loosen the tensioning star, take

the saw blade off the wheels and push it off the guide heads. Unscrew the guide heads gradually from the fixed and movable bars,

turn them by 180 ° (with bearings and hardened steel blade guides facing upwards) and screw back to the bars. Make sure that the

guide heads are perpendicular to the guide bars and that the height of the guide heads is identical. If you find special washers

between the guide head and the bar, make sure you place them back afterwards. Check the tightening of the fixed hardened steel

blade guides. Insert approximately 30 cm of an old saw blade in the guide heads between the hardened steel blade guides and the

bearings. Set the hardened steel blade guides using the width adjusting screw, so that the saw blade does moves between the guides

without any play and jamming. When the saw blade has been adjusted, set the eccentrically mounted bearings in such a manner that

the bearings do not “cut” the saw blade, but at the same time you have to prevent too much space for the saw blade between the

bearings. When the saw blade moves, the bearings are carried along by the saw blade. Make sure that all bolt connections are tight.

Unscrew the guide heads from the bars. Fit the saw blade on the wheels, check its correct alignment on the wheels and tension the

saw blade. Install both guide heads on the saw blade in the space between the bars and adjust them in the correct position on the

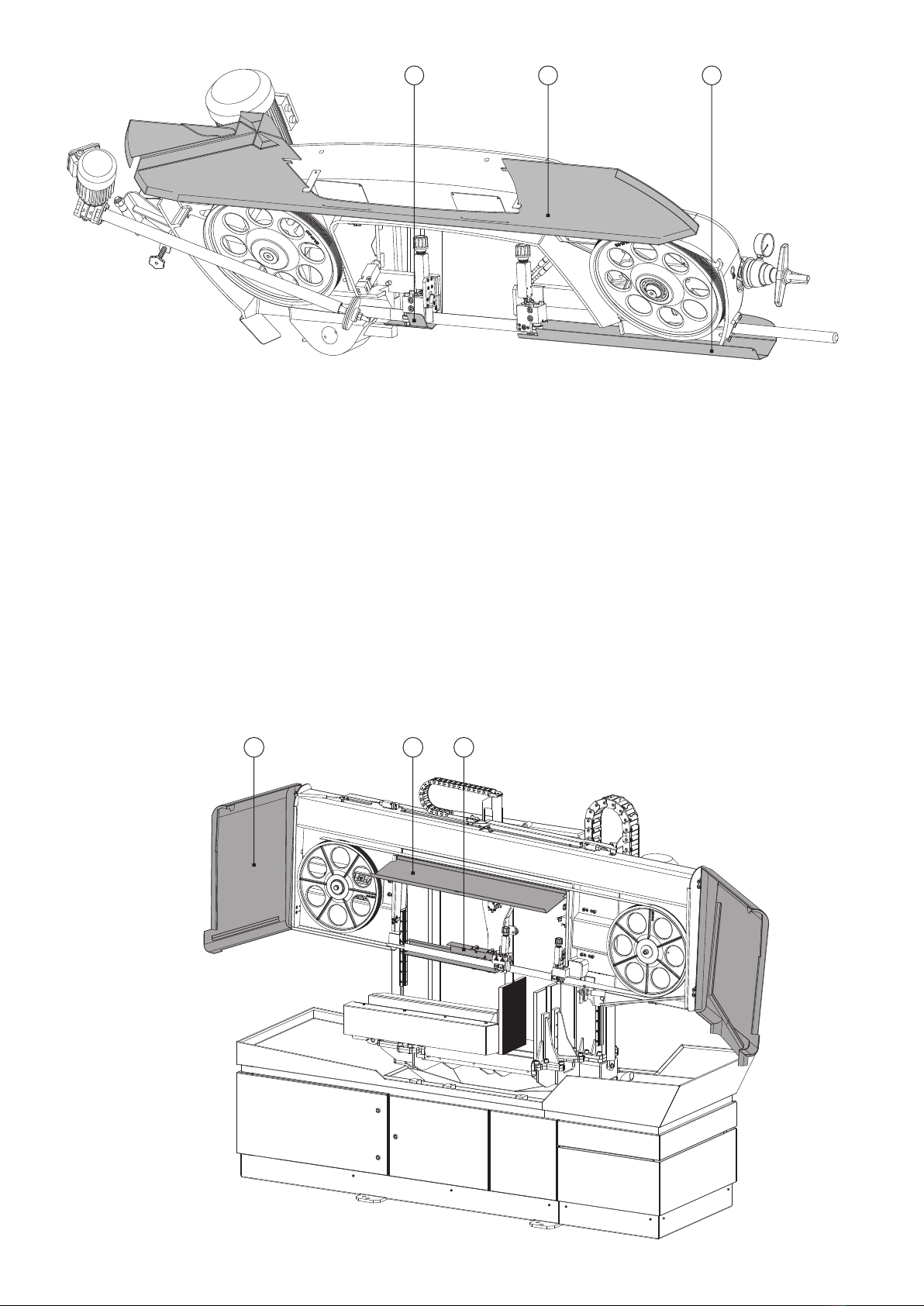

bars.You can achieve the correct guide head height in relation to the saw blade by lifting the guide heads, so that the upper hardened

steel guide in the guide head is about 0.5-1 mm away from the upper edge of the saw blade. See the picture. In this way, the correct

guide head height towards the guide bars is achieved.

Set the guide heads perpendicular to the bars and tighten them. If you fail to achieve perpendicularity, the saw blade will either keep

sliding off or running into the wheels. Put back the protective covers of the saw blade, turn on the POWER SWITCH, press the

SAFETY BUTTON and the hydraulic unit. Carry out a saw blade trial run. Switch off the POWER SWITCH and secure it against

restart, remove the protective covers of the saw blade and once again check the placement of the saw blade on the wheels. Make

a correction, if necessary - see section 4.6. Put back the protective covers of the saw blade, turn on the POWER SWITCH, press the

SAFETY BUTTON and the hydraulic unit. Carry out the cutting. You can watch the video with instructions on www.pilous.cz.

Caution: You can remove the protective covers only if the POWER SWITCH is turned off and

secured against restart or if the machine is disconnected from the mains.

Caution: Danger of injury by the sharp teeth of the saw blade. Use protective gloves. Do not

reach between the wheels and the saw blade.