Content :

7. Putting into operation

7.1. Safety control

7.2. First cut

8. Machine maintenance

8.1. Maintenance and control

8.2. Repairs

9. Errors - reasons and elimination

10. Electrical scheme and device lay-out

10.1. Electrical scheme

ARG 180, 200 Plus, 220 Plus, 230 Standard

10.2. Electrical scheme ARG 230, ARG 230 Plus,

ARG 240, ARG 240 Plus, ARG 290 Plus

10.3. Electrical device lay-out

180, 200 Plus, 220 Plus, 230 Standard

10.4. Electrical device lay-out ARG 230, ARG 230 Plus,

ARG 240, ARG 240 Plus, ARG 290 Plus

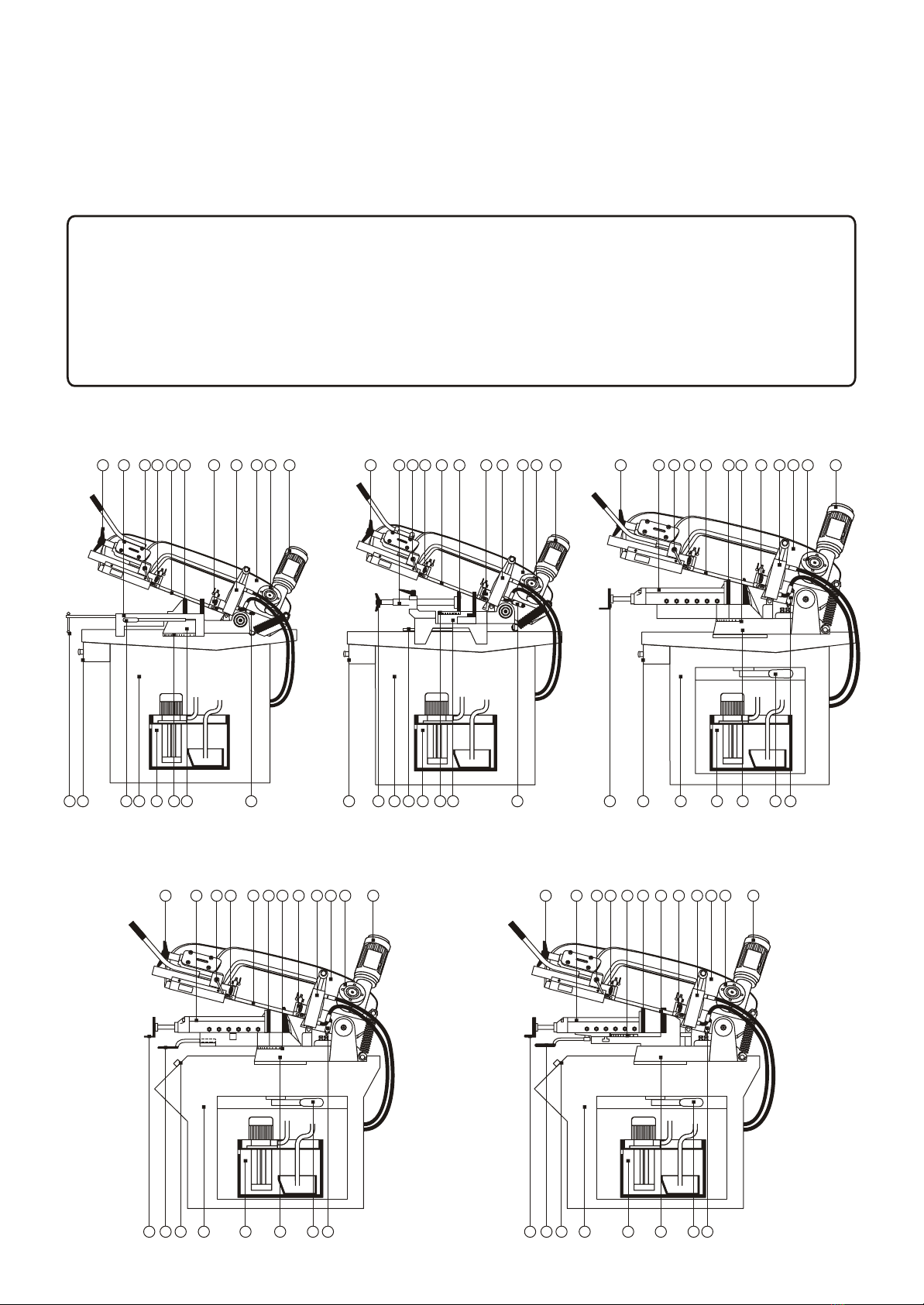

11. Assembly

11.1. Guiding heads assembly

11.2. Idler wheel assembly

11.3. Table, pivot and vice assembly

11.3.1. Table, pivot and vice assembly ARG 180

11.3.2. Turning table and pivot assembly

ARG 200 Plus, ARG 220 Plus

11.3.3. Vice assembly ARG 200 Plus, ARG 220 Plus

11.3.4. Table, pivot and vice assembly

ARG 230 Standard, ARG 230, ARG 240

11.3.5. Table, turning table, pivot and vice assembly

ARG 230 Plus, ARG 240 Plus, ARG 290 Plus

11.4. Drive assembly

11.5. Oil damper assembly

11.6. Coolant assembly

0. In general

0.1. Safety provisions

0.2. Scope of use / use by determination

0.3. Requirements concerning operators

0.4. Requirements concerning machines -

safety equipments

0.5. Protective covers

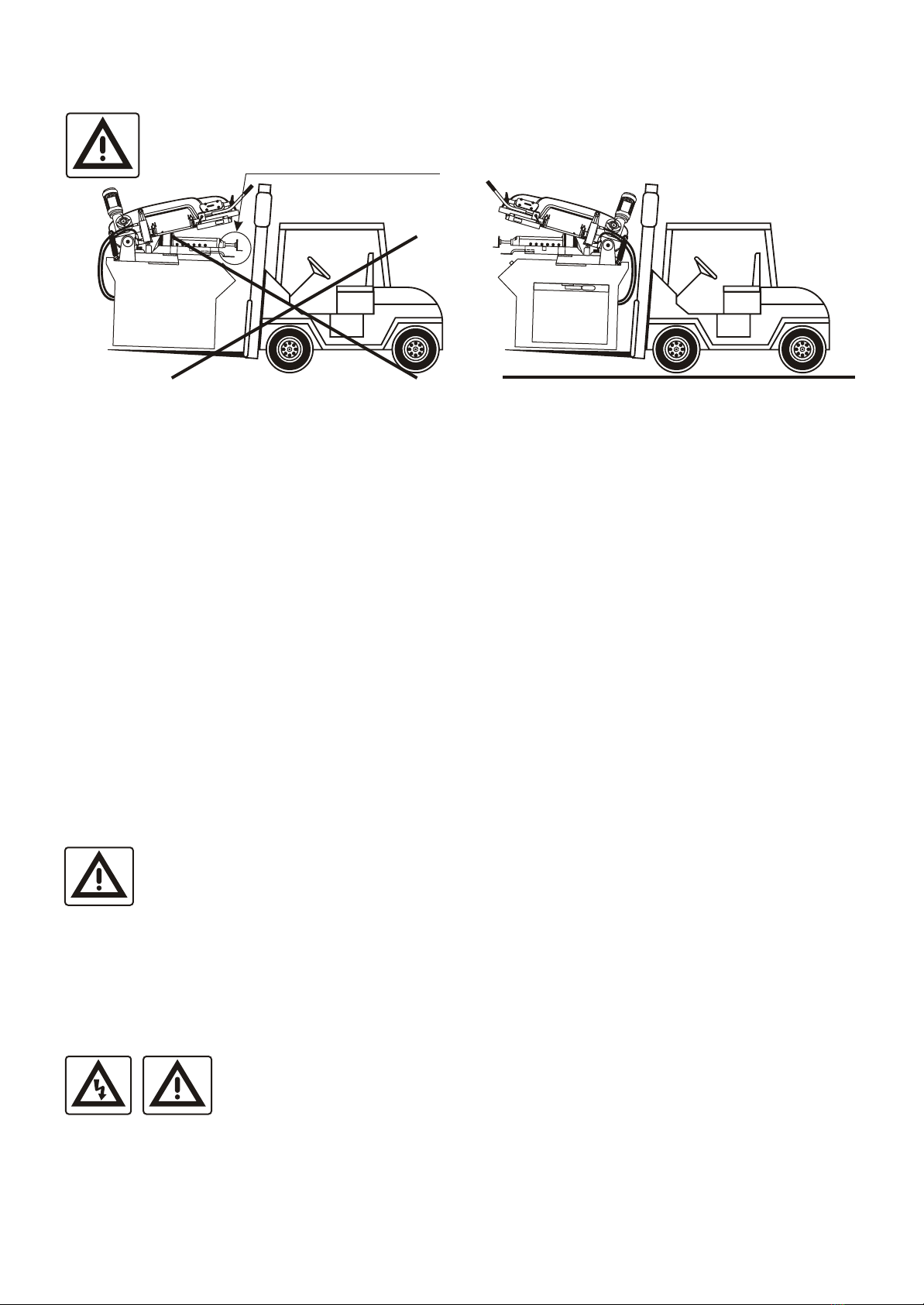

1. Transport and storage

1.1. Surface treatment

1.2. Packing

1.3. Installation

1.4. Dismantling

1.5. Disposal

2. Machine data

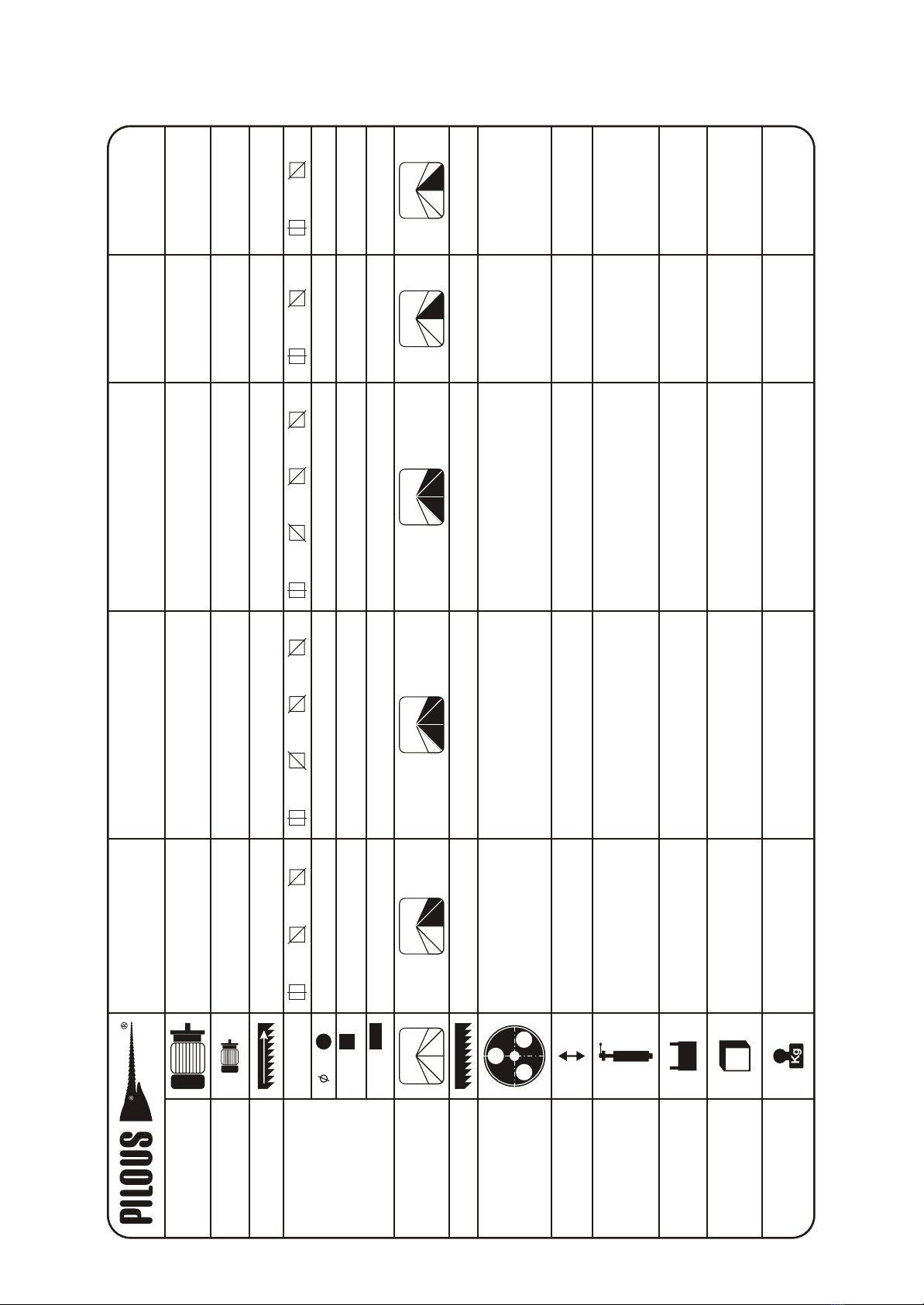

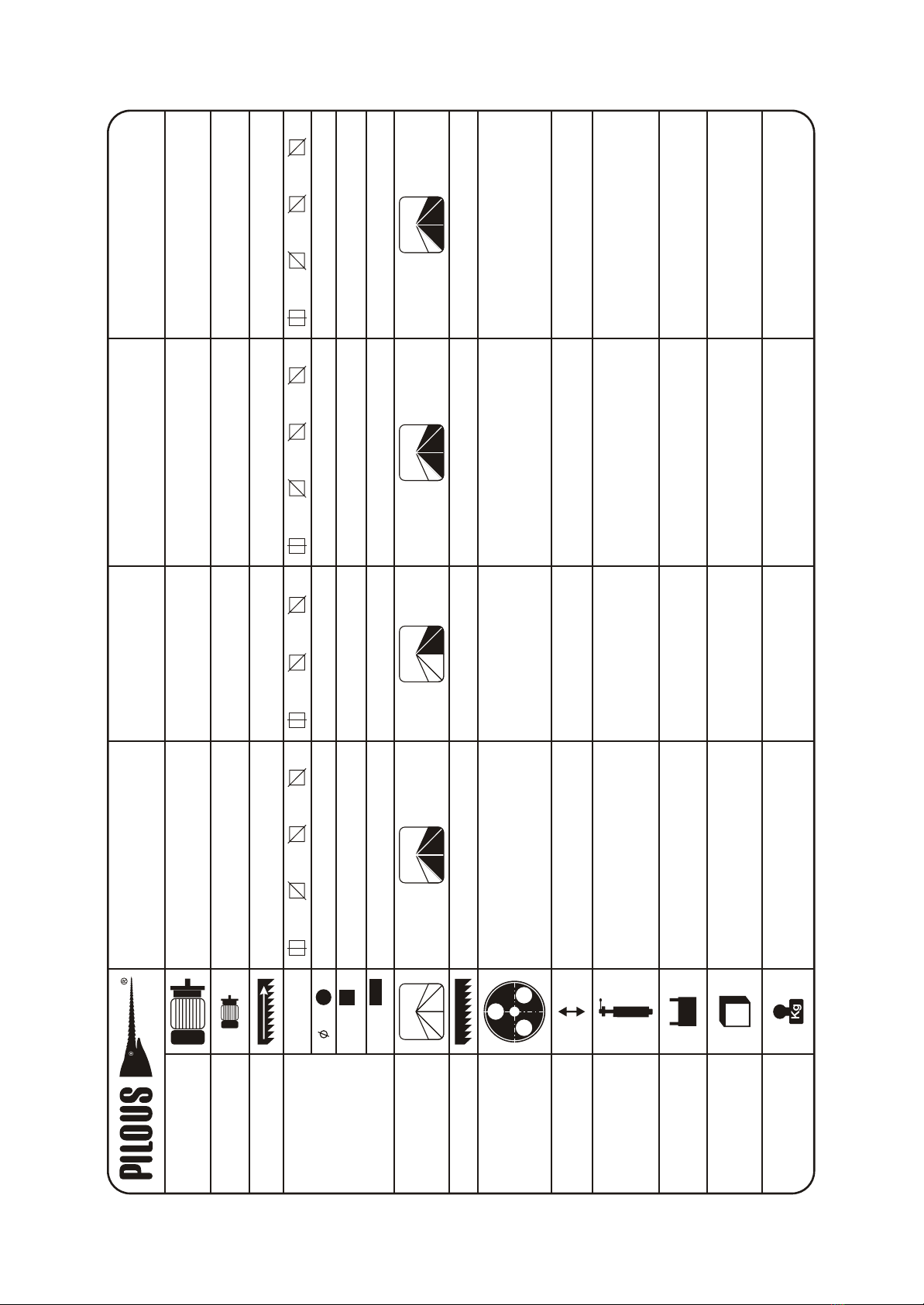

3. Technical data

4. Installation

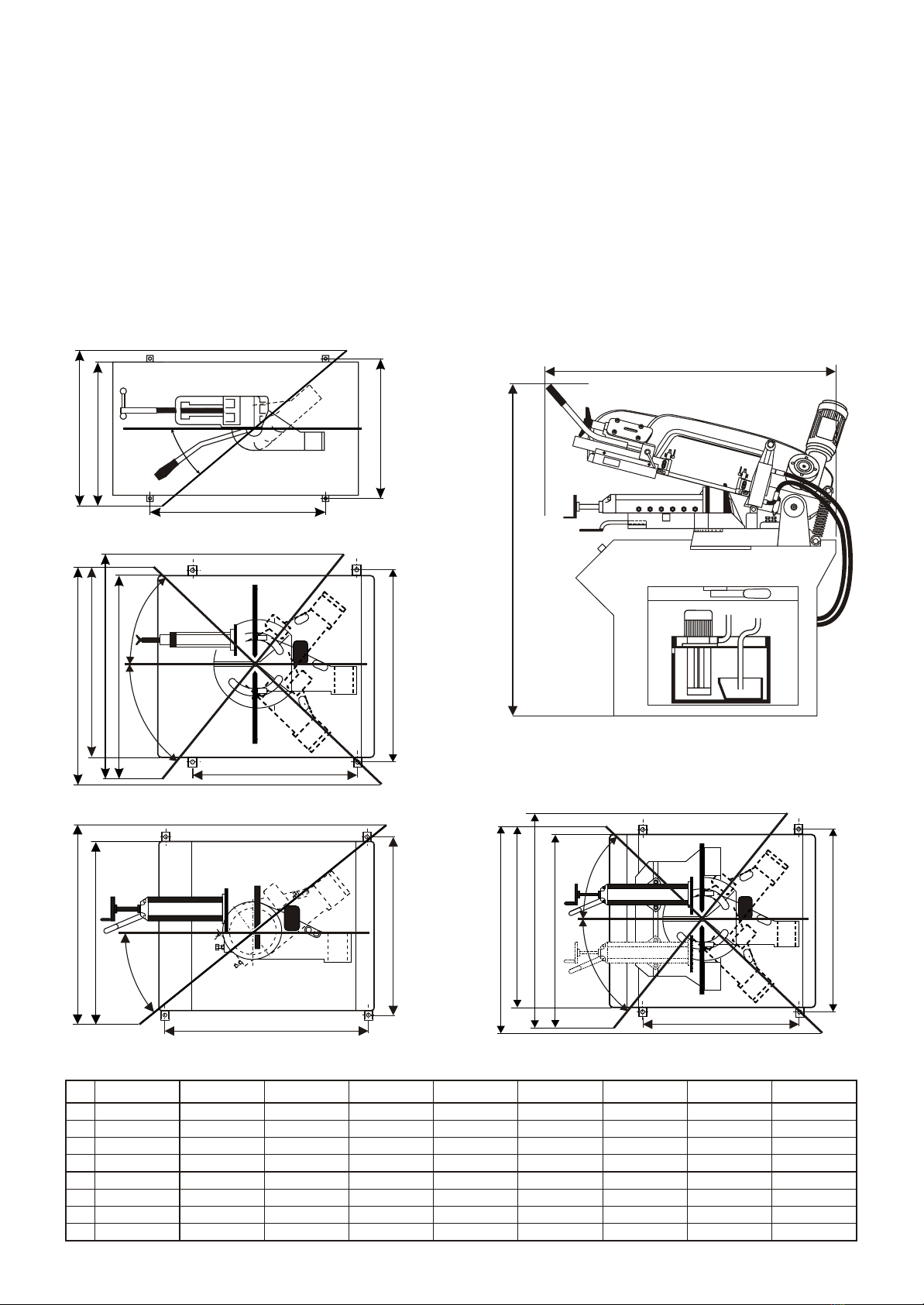

4.1. Space requirements

4.2. Machine installation

4.3. Connection to energy supplies

5. Machine description

5.1. Band guide

5.2. Band exchange, tensioning and adjustment

5.3. Guide heads - adjustment

5.4. Vice - Workpiece clamping

5.4.2. Setting of cutting angle

5.5. Control panel

5.5.1. Control panel ARG 180, ARG 200 Plus,

ARG 220 Plus, ARG 230 Standard

5.5.2. Control panel ARG 230, ARG 230 Plus,

ARG 240, ARG 240 Plus, ARG 290 Plus

5.7. Cooling equipment

6. Saw bands

6.1. Saw band design

6.2. Band tooth selection

6.3. Workpiece clamping

6.4. Running-in the bands

6.5. Factors influencing band life

6.6. Recommended values for cutting

5.4.1. Vice side clearance setting

5.6. Oil Damper - saw band feed into cut

Dear customer,

thank you for buying our product and we wish you a lot of success with it. For proper machine function please pay an

attention to this instruction manual.

© 2004 All rights particularly the right to make copies of, to distribute and translate this instruction manual are reserved.

No part of this instruction manual may be reproduced in any form (printing, microfilm or others) or sorted, processed,

copied or distributed by using electronic systems without permission of PILOUS.