1

ENGLISH

Dear customer,

Thank you for buying our product. Please read through this instruction

carefully. It will help you understand the machine and operate it smoothly.

© 2007 All rights, particularly the right to make copies of, to distribute and

translate this instruction manual, are reserved. No part of this instruction

manual may be reproduced in any form (printing, microfilm or others) or

stored, processed, copied or distribured by using electronic systems wit-

hout permission of PILOUS.

Contents:

0. In General ......................................................................................1

0.1. Safety Provisions.............................................................................2

0.2. Scope of Use / Use acc. to Specification........................................2

0.3. Requirements Concerning Operators..............................................2

0.4. Requirements Concerning Machine- Protective Enclosures ..........2

0.5. Protective Enclosures......................................................................2

1. Transport and Storage..................................................................2

1.1. Surface Treatment ...........................................................................2

1.2. Packing............................................................................................2

1.3. Dismantling/ Repackaging..............................................................2

1.4. Disposal...........................................................................................3

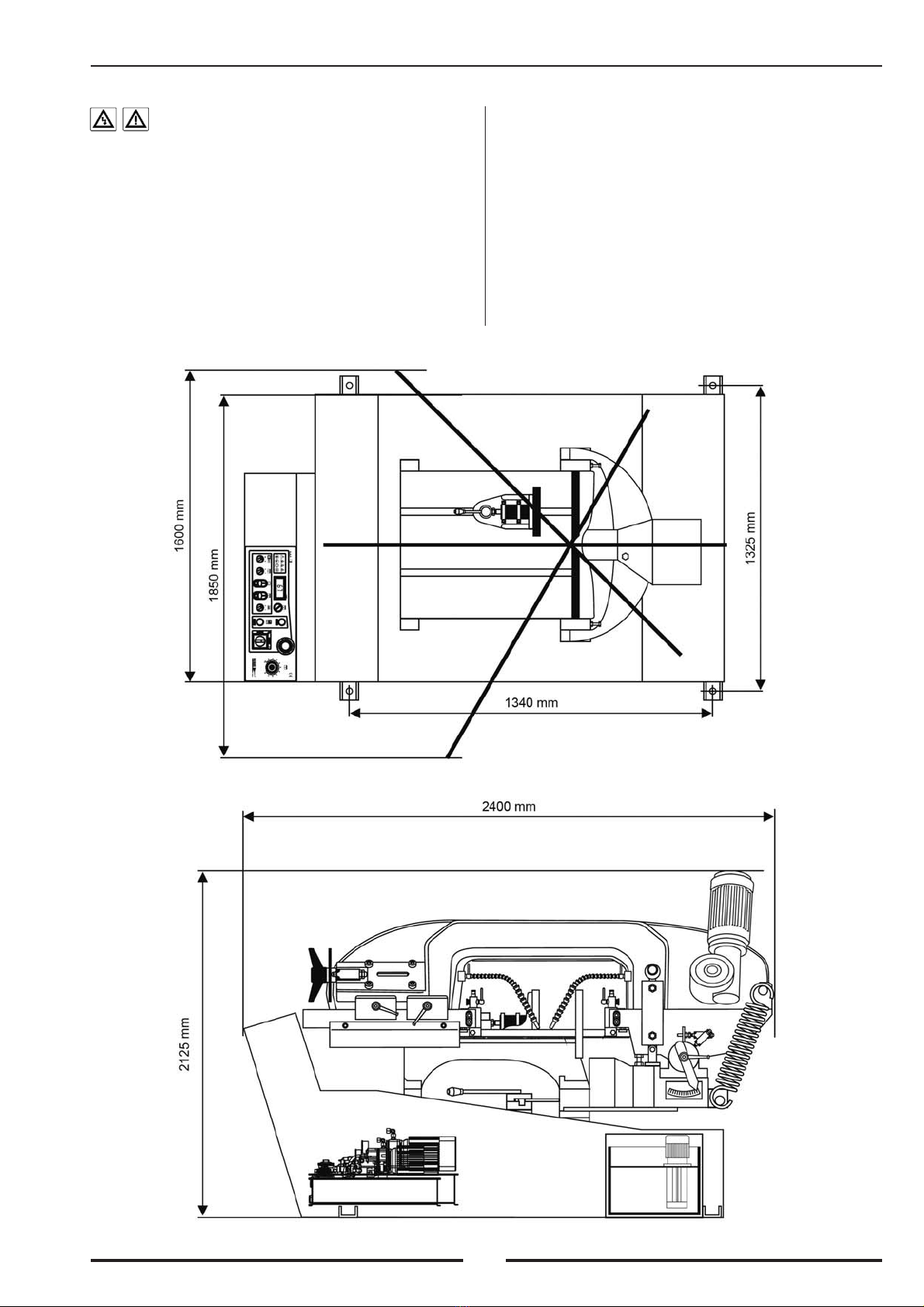

2. Installation .....................................................................................3

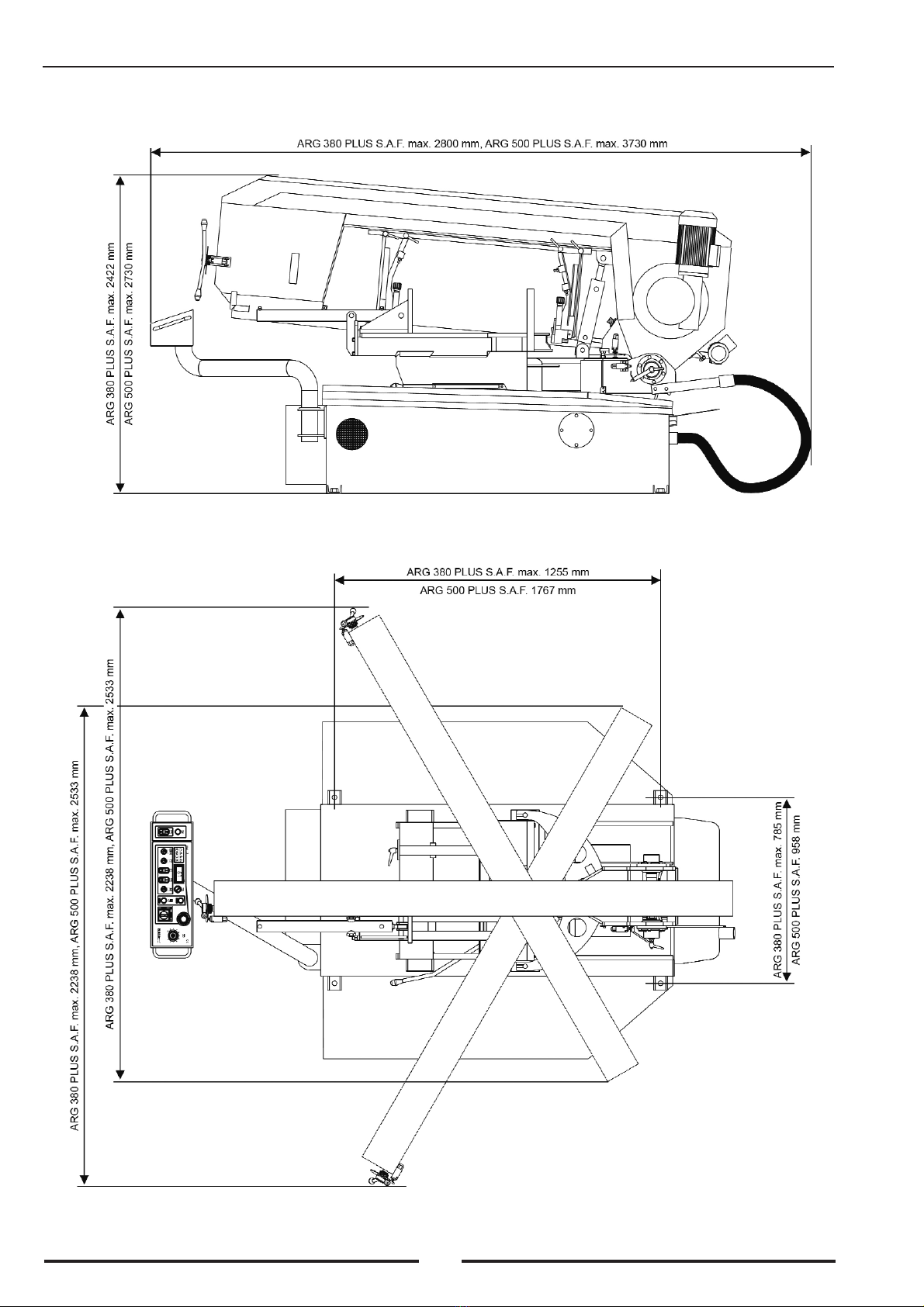

2.1. Space Requirements........................................................................3

2.2. Dismantling of Transport Beams and Machine Alignment ............5

2.3. Machine Installation........................................................................5

2.4. Connection to Energy Supplies.......................................................5

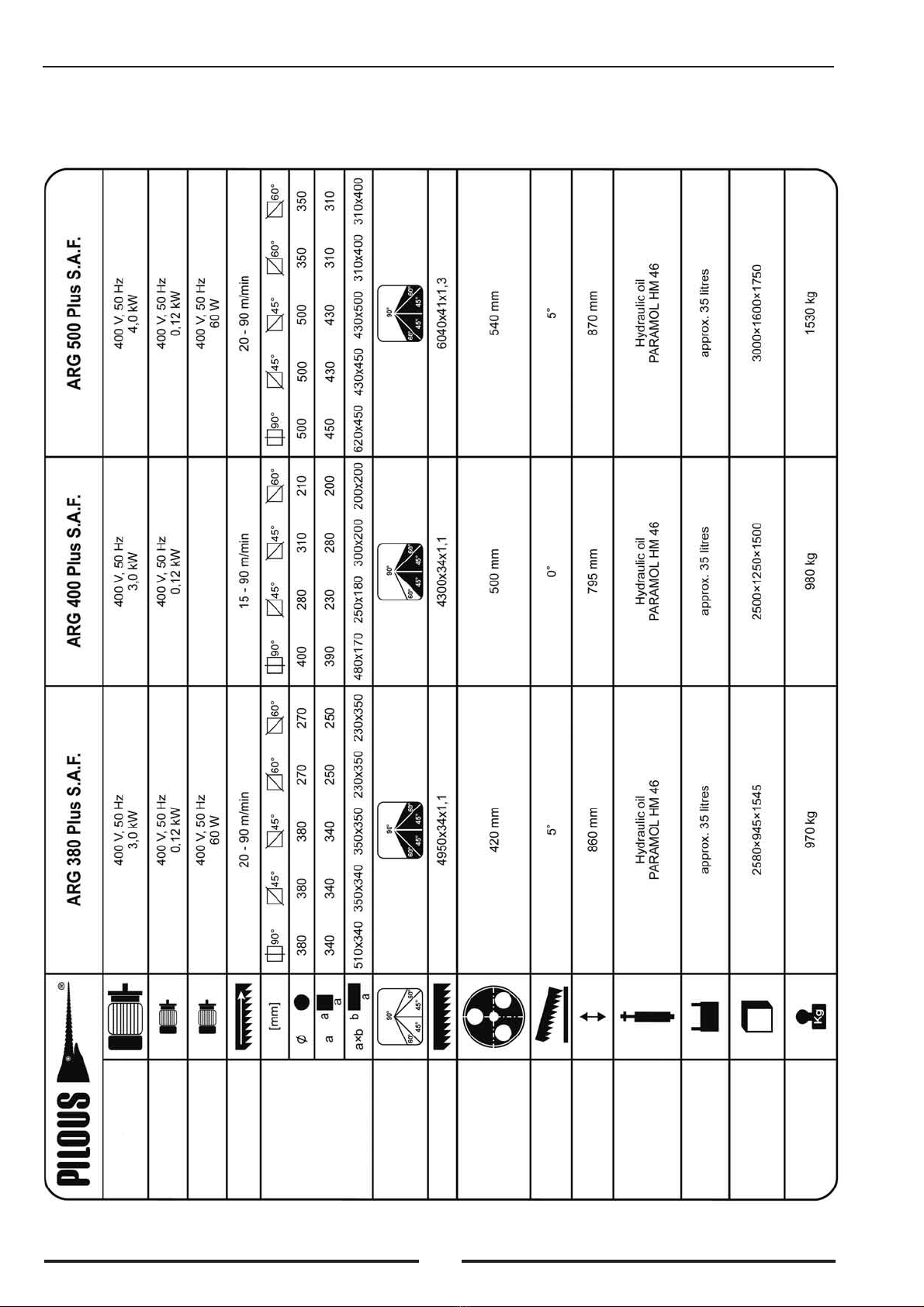

3. Technical Data ...............................................................................6

4. Machine Parameters.....................................................................7

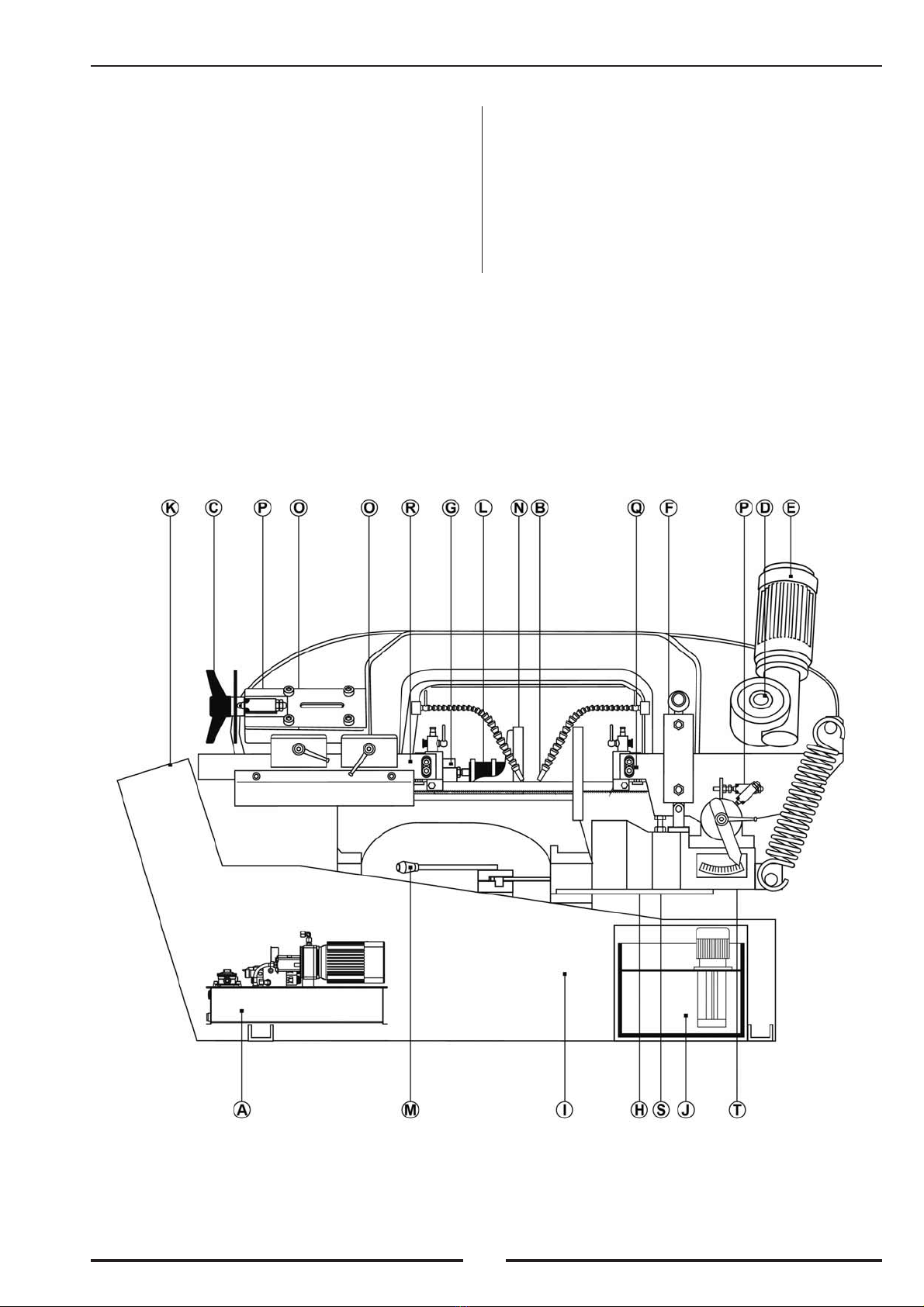

5. Machine Description...................................................................10

5.1. Vice ...............................................................................................10

5.1.1. Setting of Cutting Angle ...............................................................10

5.1.2. Material Clamping ........................................................................10

5.2. Saw Blade Feed into Cutting Position..........................................12

5.2.1. Saw Blade Feed into Cutting Position-Control valve...................12

5.3. Hydraulic Unit...............................................................................12

5.3.1. Hydraulic Unit...............................................................................12

5.3.2. Setting of Vice Clamping Force....................................................12

5.4. Setting of Band Saw Head Stroke Height ....................................13

5.5. Saw Blade Guide...........................................................................14

5.6. Saw Blade Replacement, Tension and Setting..............................14

5.7. Guide Heads - Setting ...................................................................14

5.8. Regulation of Saw Blade Cutting Pressure...................................16

5.9. Control Panel.................................................................................16

5.10. Cooling System.............................................................................21

6. Saw Blades ...................................................................................22

6.1. Saw Blade Design .........................................................................22

6.2. Tooth Size......................................................................................22

6.3. Optimum Workpiece Clamping ....................................................23

6.4. Running-in New Saw Blades........................................................23

6.5. Factors Influencing Saw Blade Life .............................................23

6.6. Values Recommended for Sawing ................................................23

7. Putting into Operation................................................................25

7.1. Safety Control ...............................................................................25

7.2. First Cut.........................................................................................25

8. Machine Maintenance.................................................................25

8.1. Maitenance and Checking.............................................................25

8.2. Repairs...........................................................................................26

Extra Accessorie Angle calibration.......................................................26

9. Failures and their Elimination..........................................................27

Attachment to operating instructions for hydraulic unit...................28

10. Wiring Diagram and Arrangement of Switching

and Protective Elements.............................................................91

10.1. Wiring Diagram ARG 400 Plus S.A.F..........................................91

10.2. Wiring Diagram ARG 380 Plus S.A.F.,

ARG 500 Plus S.A.F. ....................................................................93

10.3. Wiring Diagram ARG 380 Plus S.A.F. Electronic,

ARG 500 Plus S.A.F. Electronic...................................................96

11. Assemblies....................................................................................99

11.1. Guide Head Assembly...................................................................99

11.1.1.Guide Head Assembly ARG 380, 500 Plus S.A.F........................99

11.1.2.Guide Head Assembly ARG 400 Plus S.A.F.

11.2. Bow Assembly ............................................................................100

11.2.1.Bow Assembly ARG 380, 500 Plus S.A.F..................................100

11.2.2.Bow Assembly ARG 400 Plus S.A.F.

11.3. Table, Turntable, Joint & Vice Assembly ...................................102

11.3.1.Table, Turntable, Joint & Vice Assembly

ARG 380, 500 Plus S.A.F. ..........................................................102

11.3.2.Table, Turntable, Joint & Vice Assembly

ARG 400 Plus S.A.F.

11.4. Saw Blade Drive & Tensioning Mechanism Assembly..............104

11.4.1.Saw Blade Drive & Tensioning Mechanism Assembly

ARG 380, 500 Plus S.A.F. ..........................................................104

11.4.2.Saw Blade Drive & Tensioning Mechanism Assembly

ARG 400 Plus S.A.F.

11.5. Driven Cleaning Brush Assembly...............................................105

11.6. Blade Hydraulic Tensioning Assembly (Accessories)................106

12. Hydraulic Diagram ...................................................................107

0. In General

This instruction manual provides the user assistance and information about

the PILOUS band saw and the possibilities of use corresponding to its pur-

pose. The instruction manual contains important instructions for safe, ade-

quate and economically efficient operation. Observing the operating

instructions will prevent hazards, reduce the repair and outage time costs,

and increase the machine reliability and life. The instruction manual con-

tains instructions based on the existing national regulations concerning pre-

vention of accidents and environmental protection. The instruction manual

must always be available at the machine site. The instruction manual must

be read and used by the staff entrusted with the machine installation, trans-

port and storage, use, operation, maintenance and disposal. In addition to

the instruction manual and the binding rules related to accident prevention

valid in the user's country and at the service site, it is also necessary to

observe the approved rules for safe and professional work.

Letter of Guarantee - Service

The Letter of Guarantee is a separate attachment to the instruction manual.

Guarantee period - see Letter of Guarantee

Conditions for Maintenance of Claims under Guarantee

• Transport and storage of the machine in conformity with the instruction

manual.

• Use and attendance of the machine in conformity with the instruction

manual.

• Connection of the machine to voltage in conformity with the instruction

manual.

The guarantee does not apply to:

• Violent and mechanical damage of the machine caused by interference of

the user or other persons.

• Unavoidable event (natural disaster).

• Damage of machine during transport.

• Storage or installation of machine in humid, chemical or any other unsu-

itable environment.

• Parts subject to wear and tear (see Letter of Guarantee ).

Any claims concerning guarantee and after-guarantee repairs should

be sent by fax, mailed or communicated by phone to the following add-

ress: refer to the Letter of Guarantee.