Contents:

8. Failures

9. Failures and their Elimination

10. Machine Maintenance

10.1. Maintenance and Checking

10.2. Repairs

11. Saw Blades

11.1. Saw Blade Design

11.2. Tooth Size

11.3. Optimum Workpiece Clamping

11.4. Running-in New Saw Blades

11.5. Factors Influencing Saw Blade Life

11.6. Values Recommended for Sawing

12. Wiring Diagram and Arrangement

of Switchingand Protective Elements

12.1. Wiring Diagram ARG 220 D-NC Automat

12.2. Arrangement of Switching and Protective Elements

ARG 220 D-NCAutomat

12.3. Wiring Diagram ARG 220 DF-NC Automat

12.4. Arrangement of Switching and Protective Elements

ARG 220 DF-NCAutomat

12.5. Wiring Diagram

ARG 250 D-NCAutomat, ARG 300 D-NCAutomat

12.6. Arrangementof Switching and Protective Elements

ARG 250 D-NCAutomat, ARG 300 D-NCAutomat

12.7. Wiring Diagram

ARG 250 DF-NCAutomat, ARG 300 DF-NCAutomat

12.8. Arrangement of Switching and Protective Elements

ARG 250 DF-NCAutomat, ARG 300 DF-NCAutomat

12.9. Wiring Diagram

ARG 250 C-NCAutomat, ARG 300 C-NCAutomat

12.10. Arrangementof Switching and Protective Elements

ARG 250 C-NCAutomat, ARG 300 C-NCAutomat

12.11. Wiring Diagram

ARG 250 CF-NCAutomat, ARG 300 CF-NCAutomat

12.12. Arrangementof Switching and Protective Elements

ARG 250 CF-NCAutomat, ARG 300 CF-NCAutomat

13. Assembly

13.1. Guide Head Assembly

13.2. Arm Assembly

13.3. Assembly of PLC control

13.4. Cooling System Assembly

0. In General

0.1. Safety Provisions

0.2. Scope of Use / Use acc. to Specification

0.3. Requirements Concerning Operators

0.4. Requirements Concerning Machine - Protective Enclosures

0.5. Protective Enclosures

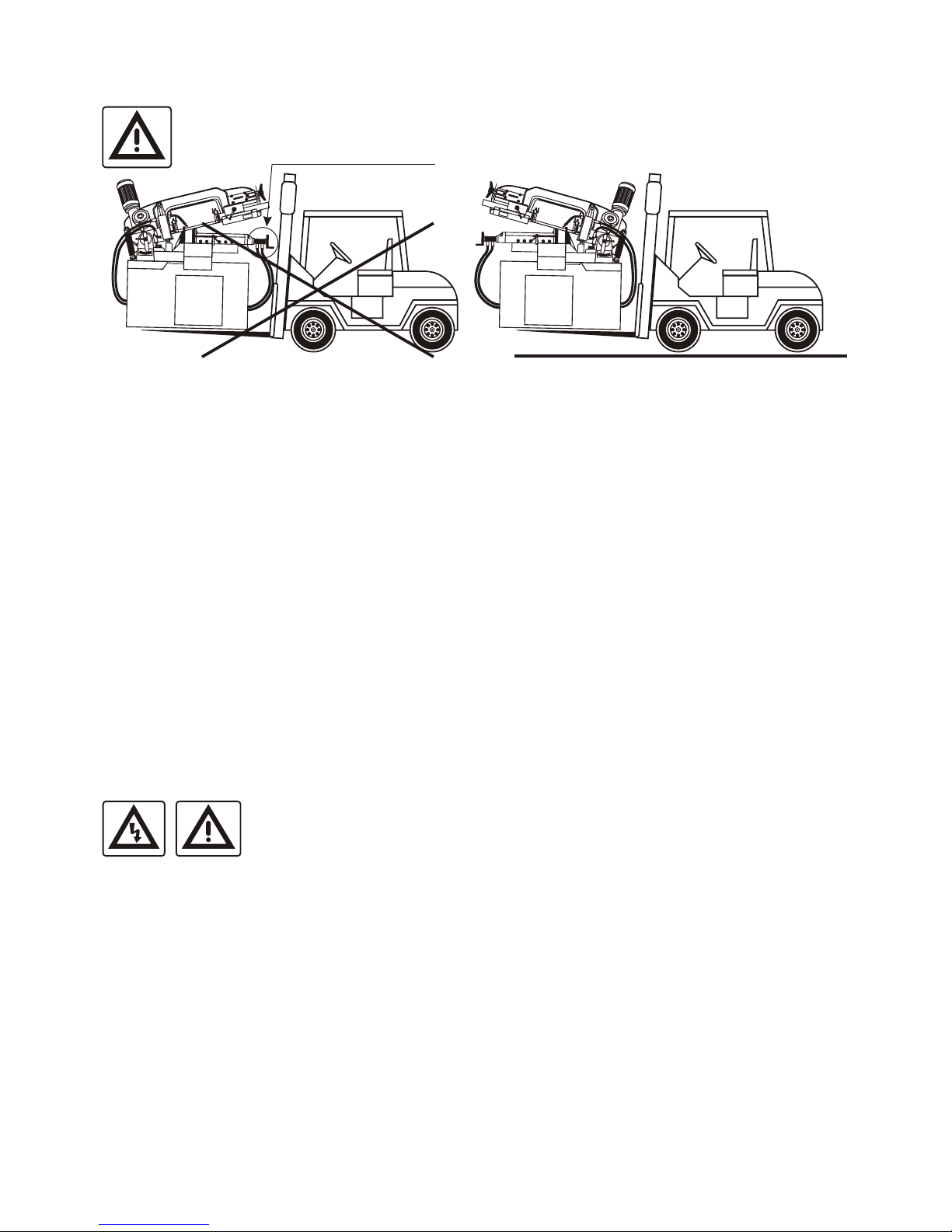

1. Transport and Storage

1.1. Surface Treatment

1.2. Packing

1.3. Dismantling/Repackaging

1.4. Disposal

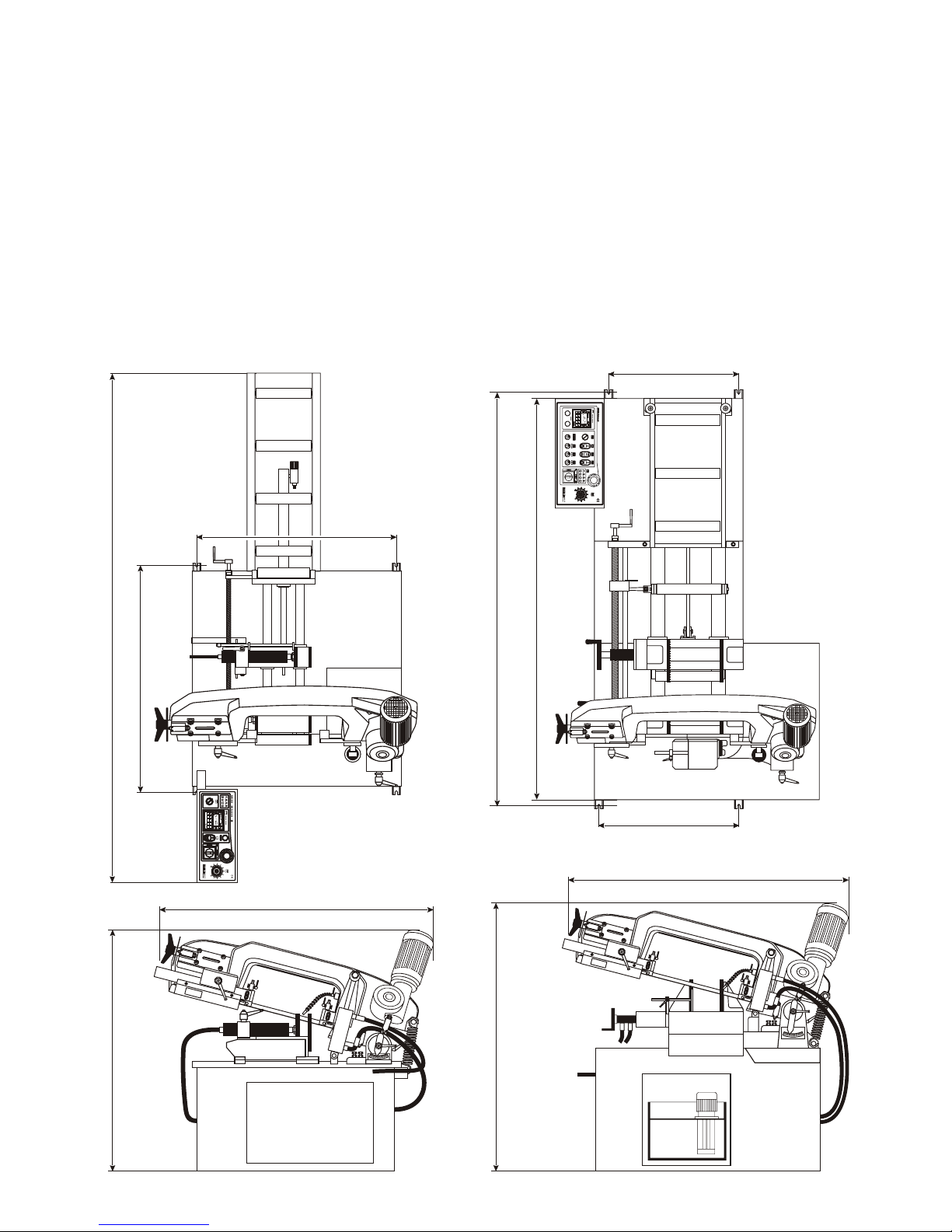

2. Installation

2.1. Space Requirements

2.2. Dismantling of Transport Beams and Machine Alignment

2.3. Machine Installation

2.4. Connection to Energy Supplies

3. Technical Data

4. Machine Description

4.1. ARG 220 D(F)-NC Automat

4.2. ARG 250 D(F)-NC Automat

4.3. ARG 250 C(F)-NC Automat

4.4. ARG 300 D(F)-NC Automat

4.5. ARG 300 C(F)-NC Automat

5. Description of Individual Units

5.1. Setting of Cutting Angle

5.2. Material clamping

5.2.1. Setting of Vice Clamping Force

5.2.2. Setting of Vice Side Clearance

5.2.3. Moving Viced Feed System

5.2.4. Setting of Feeding Speed of Moving Vice

5.2.5. Setting der Auxiliary Roller

5.2.6. Pressure Device for Bundle Cutting

5.3. Saw Blade Guide

5.3.1. Saw Blade Replacement, Tension and Setting

5.3.2. Guide Head Setting

5.4. Saw Blade Feed into Cutting Position

5.5. Setting of Band saw Head Strke Height

5.6. Hydraulic Unit

5.7. Cooling System

6. Description of Control Board and Setting of

VISION Control Unit

6.1. ARG 220 D(F)-NC Automat

6.2. ARG 250 D(F)-NC Automat,

ARG 300 D(F)-NC Automat

6.3. ARG 250 C(F)-NC Automat,

ARG 300 C(F)-NC Automat

7. Putting into Operation

7.1. ARG 220 D(F)-NC Automat - First Cut

7.2. ARG 250, 300 NC Automat - First Cut

Dear customer,,

Thank you for buying our product. Please read through this instruction carefully. It will help you understand the machine

and operate it smoothly.

© 2007 Al rights, particularly the right to make copies of, to distribute and translate this instruction manual, are

reserved. No part of this instruction manual may be reproduced in any form (printing, microfilm or others) or stored,

processed, copied or distributed by using electronic systems without permission of PILOUS.