YOU ARE NOW READY TO TEST THE OPERATION OF

YOUR STARLINER.

We recommend trying the StarLiner with water before using paint.

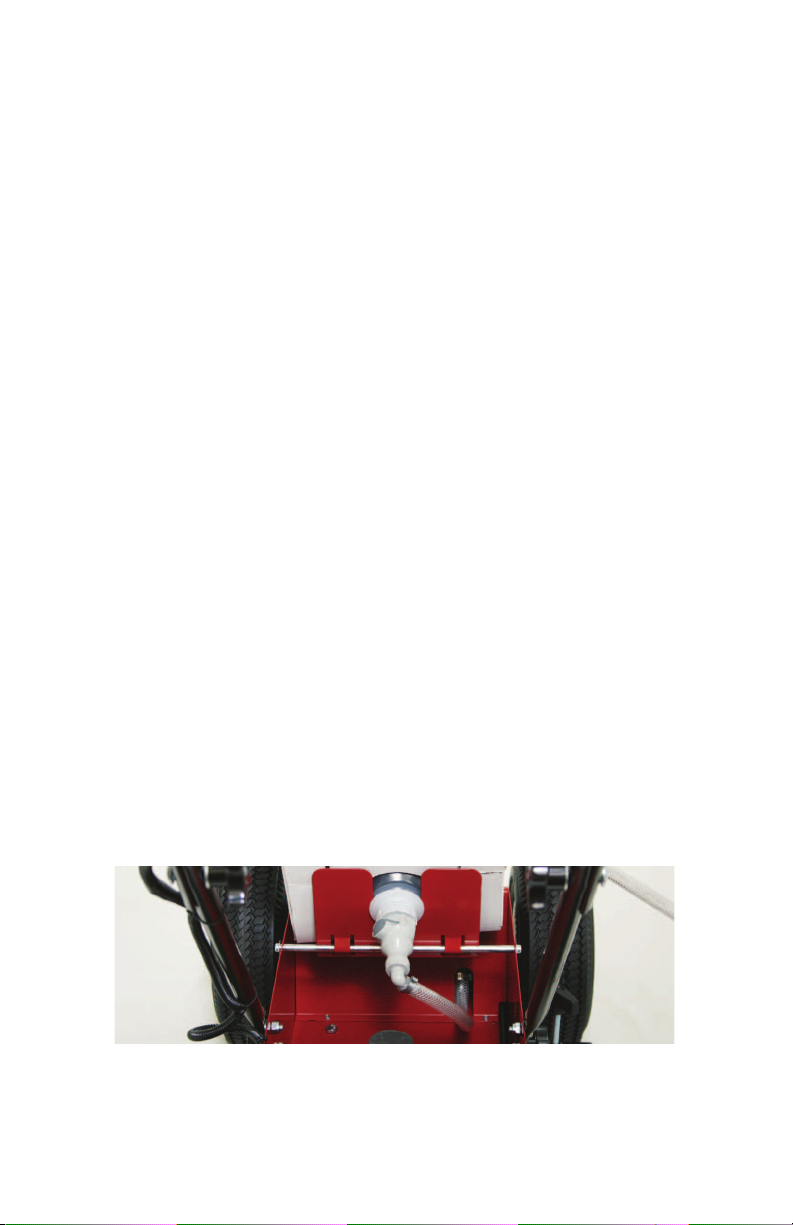

Connect the clean-out hose to the quick connect on the StarLiner. You will

hear an audible click when the hose is connected properly. After connecting,

place the clean-out hose in a bottle lled with water. Turn the switch on the

handle to the “ON” position. The pump should draw the water from the bottle.

Move the StarLiner in a forward direction to check the line width. Turn the

switch to the “OFF” position to stop the ow of water. Water typically sprays

1/3 farther than paint. Adjust your line width accordingly. You can also change

tips to achieve different line widths. Walking speed plays the largest part in

how far you can paint with one box of paint.

When you are ready to use the paint, disconnect the clean-out hose

by pressing the button on the machine side of the hose. The Clean-out

hose should pop off.

Follow the paint preparation instructions on the StarLine paint carton:

CAUTION: PIONEER STARLINE PAINT IS SPECIFICALLY DESIGNED TO

WORK WITH THE STARLINER. ANY OTHER PAINT USED WITH THIS

MACHINE MAY RESULT IN POOR LINE PERFORMANCE, CLOGGING,

AND/OR PUMP DAMAGE. THIS MAY VOID ANY AND ALL WARRANTIES

ASSOCIATED WITH THE STARLINER.

Insert the StarLine paint carton onto the StarLiner plate assembly. The

plastic lip of the paint bag should slide through the plate-slot. This will

hold the bag in place while connecting. Support the box and connect the

StarLiner paint connector with the StarLine paint. You will hear an audible

click when the proper connection is made.

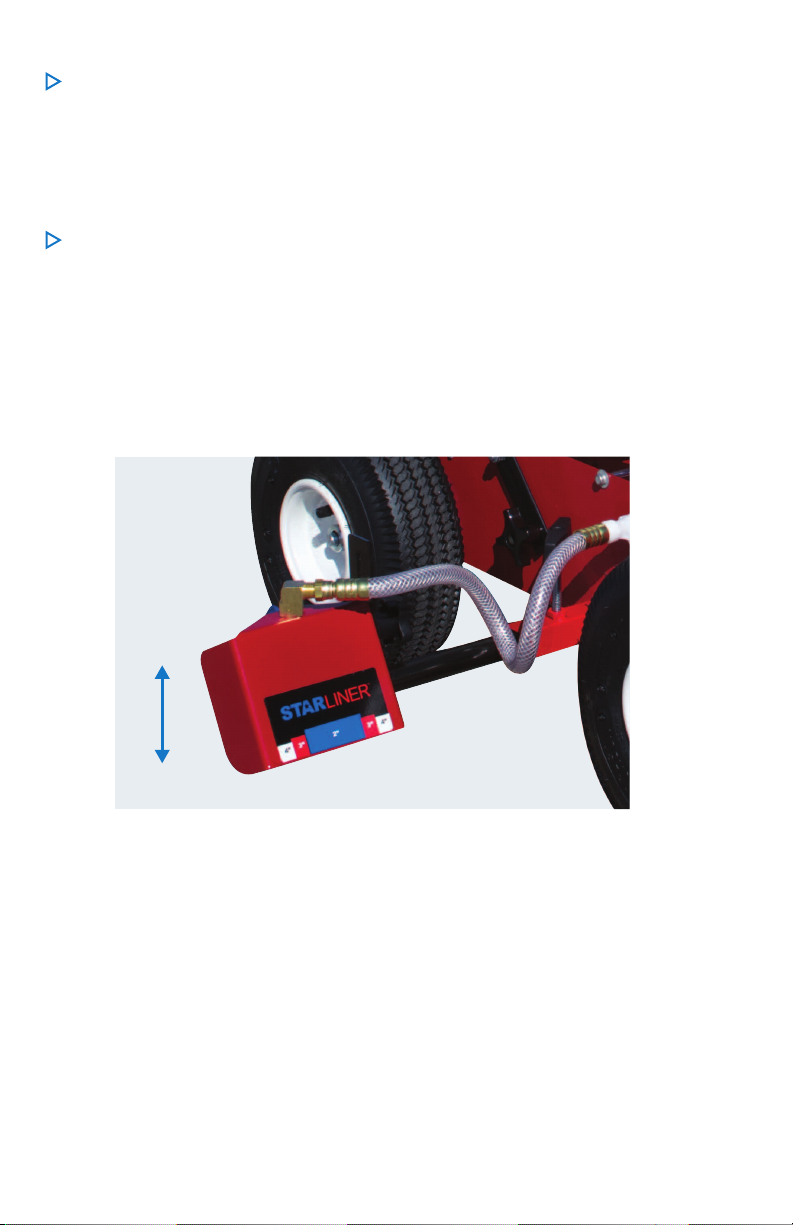

Once secure, lower the StarLine box to the battery cover. You are now

ready to begin striping. We recommend practicing in an off area so

you can get accustomed to the operation of all switches and to select

the tip that best suits your needs.

4