Part No. 4801-5154 Rev 4-08 Table of Contents 500 ST Door

Table of Contents

1. Ratings and Specifications...........................................................................................................................3

2. Warnings (Avertissements)..........................................................................................................................4

3. Limited Warranty.........................................................................................................................................8

4. Physical Description/Drawing .....................................................................................................................9

5. Use of Equipment ........................................................................................................................................9

6. Installation ...................................................................................................................................................9

6.1 Tools Required......................................................................................................................................9

6.2 Overview ..............................................................................................................................................9

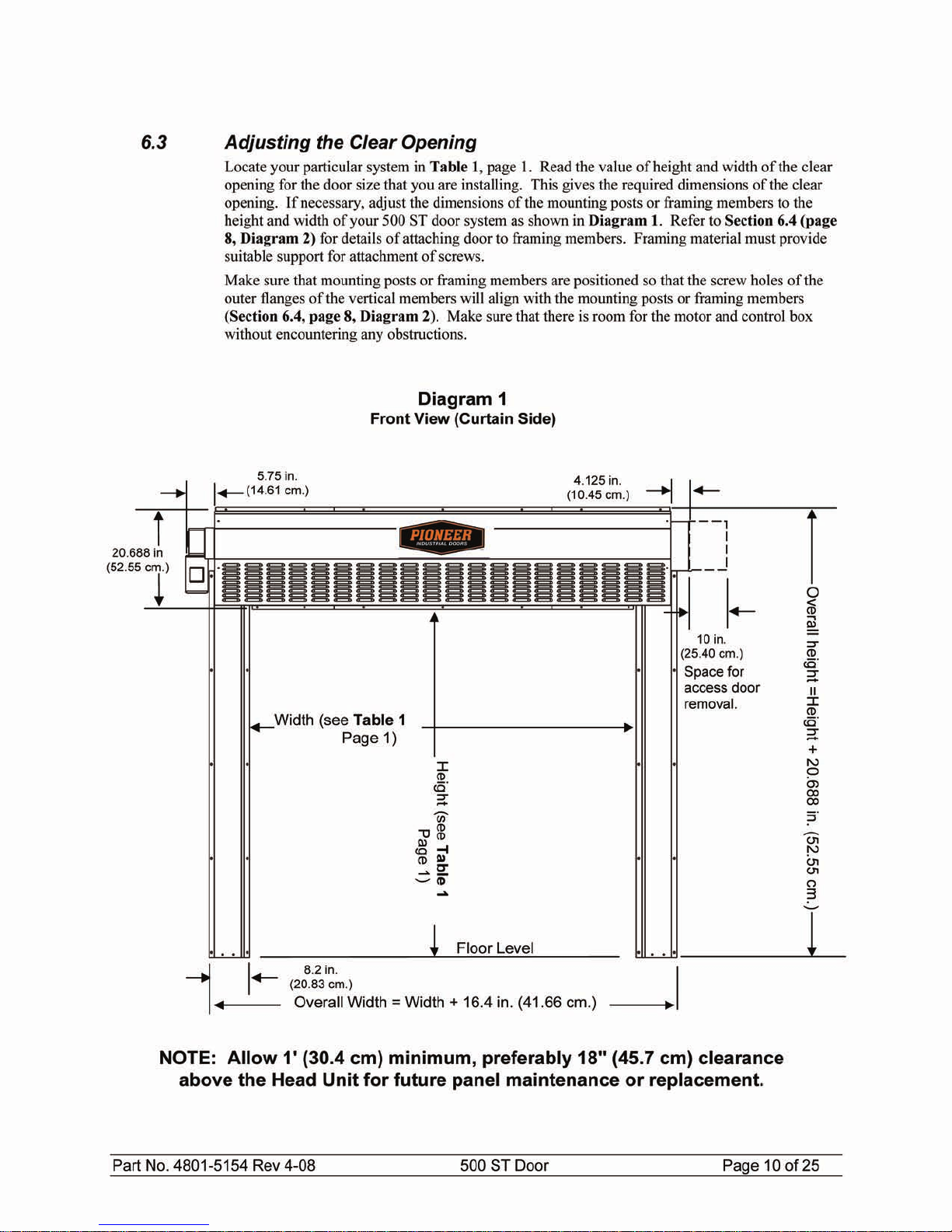

6.3 Adjusting the Clear Opening .............................................................................................................10

6.4 Attachment Points of Door................................................................................................................11

6.5 Assembly of Parts...............................................................................................................................12

6.6 Infrared Sensor Connectors ................................................................................................................13

6.7 Fastening Door Assembly to Clear Opening......................................................................................13

6.8 Connecting the Electrical Power.........................................................................................................15

7. Operation of Door......................................................................................................................................15

8. Limit Switches...........................................................................................................................................15

9. Manual Operation of Door.........................................................................................................................16

9.1 Operating Instructions ........................................................................................................................16

9.2 Adjustment of Brake...........................................................................................................................17

10. Emergency Egress......................................................................................................................................18

11. Door Panel Adjustments............................................................................................................................20

12. 500 ST Door Wiring Diagram ...................................................................................................................21

13. Pioneer Smart Controller Wiring Diagram................................................................................................22

Please Retain This Manual for Future Reference