Introduction 6

Introduction

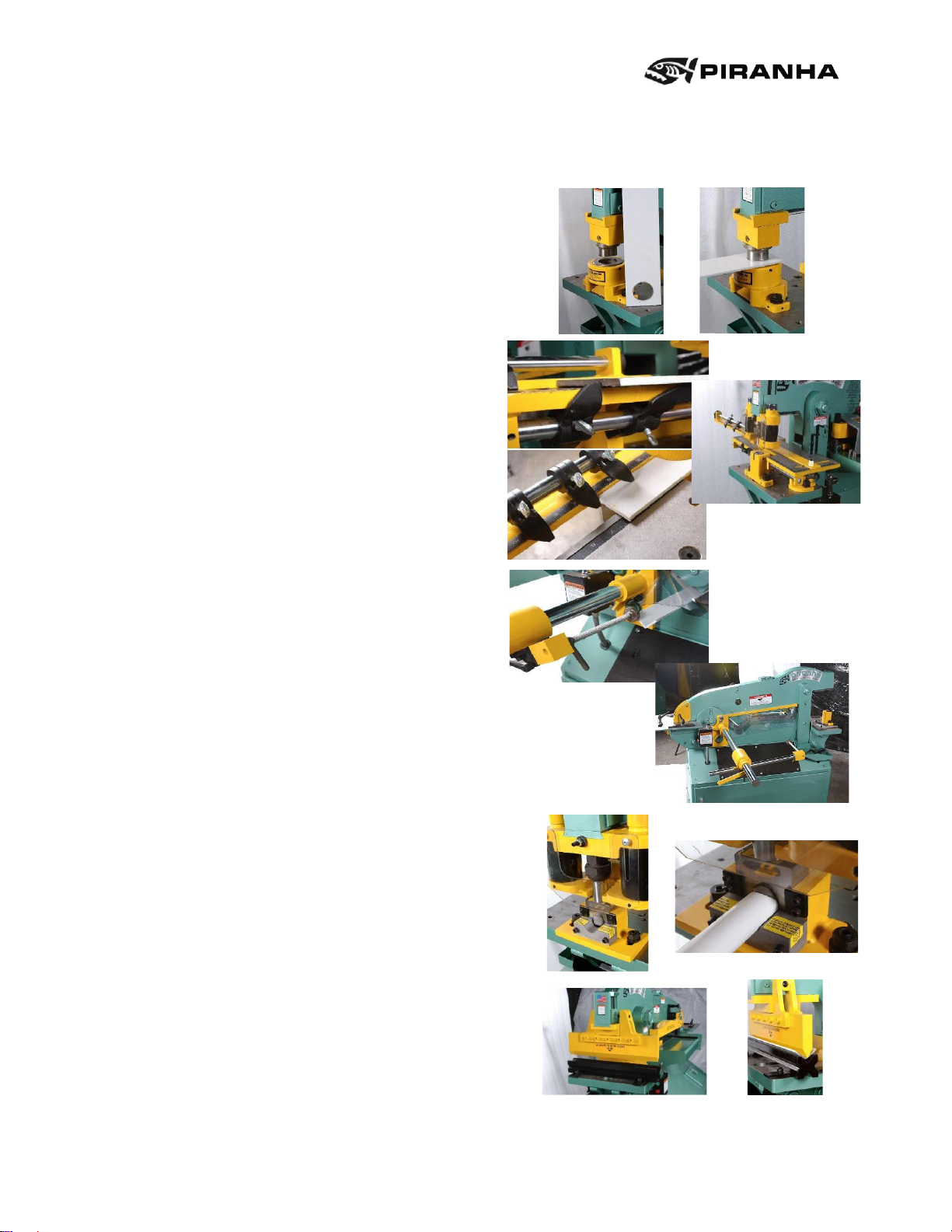

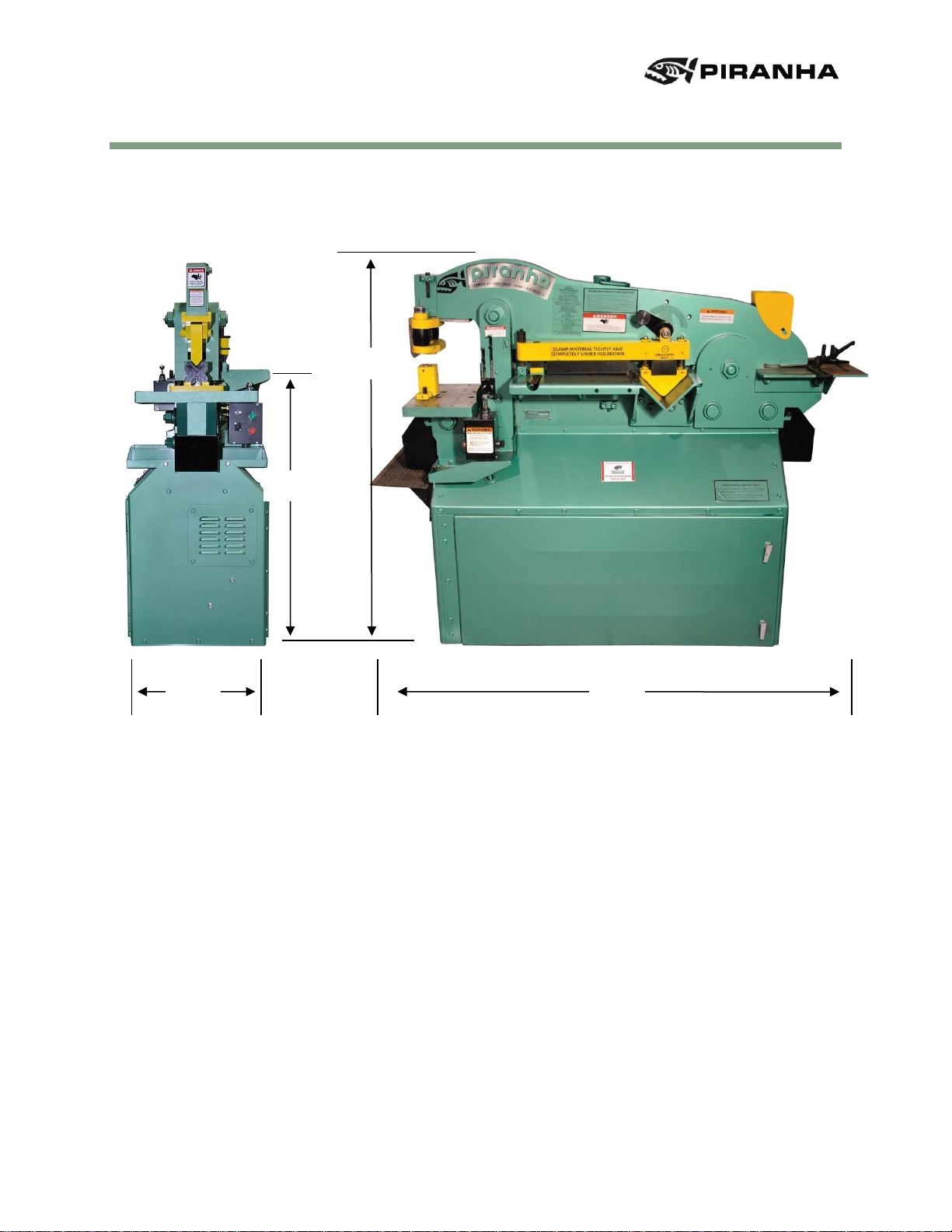

The Piranha Ironworker is a compact hydraulically powered machine that shears,

punches, bends, notches, and copes, all in a low silhouette, efficiently designed unit,

resulting in minimal floor space requirements. The integral lifting lug provides instant

portability and the unit arrives fully assembled, requiring only the addition of hydraulic oil

and electrical power to become fully operational. A quick-change mounting assembly,

utilizing a split dovetail, allows setup from punching to bending in less than one minute.

The large platen has seventeen 5/8-11 tapped holes giving a wide base for increased

flexibility of attachment sizes. The shearing operation features an adjustable automatic

hold-down allowing the operator to clamp the work piece with a slight initial adjustment.

All workstations are located approximately 44" off the floor for ease of operation.

The first part of this manual provides operations and maintenance instructions, including

a section on troubleshooting various problems that may occur. The second part of this

manual provides repair parts information and a complete parts list with their respective

part numbers.

Proper understanding and application of the information and procedures given in this

manual will aid in establishing a preventative maintenance program and, provide

assistance for correcting malfunctions that may occur in the machine. The repair parts list

provides information for parts procurement as well as assembly breakdowns to aid in

disassembly and reassembly for repair part installation.

About Piranha

Piranha is a subsidiary of MegaFab, based in Rockford Illinois. MegaFab is a

manufacturer of metal fabrication machinery, including laser cutting machines, plasma

cutting machines, ironworkers, press brakes, bending rolls, combination punching and

cutting machines, and structural steel punching equipment. Equipment is sold under the

Piranha, Whitney, and Bertsch brands.