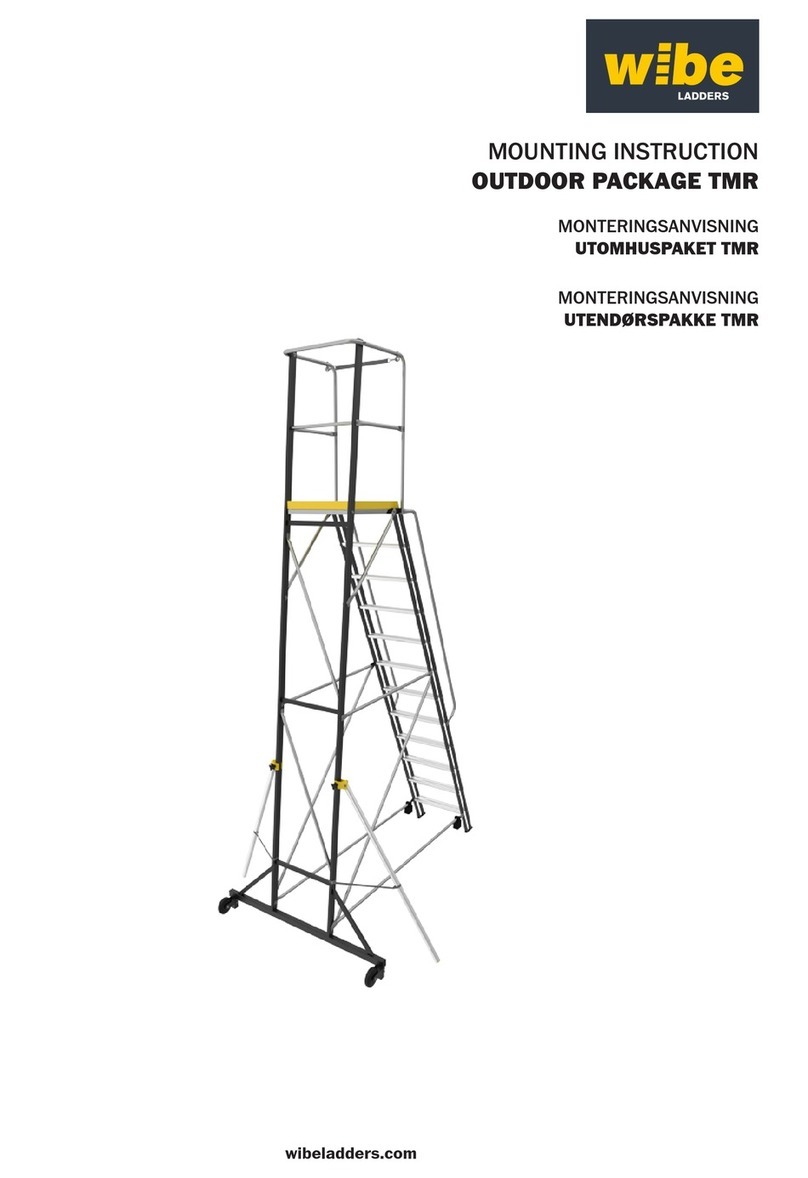

• The ladder must be dimensioned so that the topmost rung is

located ± 100 mm above the eaves or other access platform.

The bottom rung must be located 1,000–1,200 mm above the

ground or other departure surface.

INSTALLATION

Distance to the bottom

rung: 1,000–1,200 mm

Maximum distance between the pairs

of wall ladder legs: 3,000 mm

Minimum distance between

the rung and the nearest

protrusion: 200 mm

200,0-1200,0

NOTE! If a safety rail is fastened

to the ladder, at least four pairs

of wall ladder legs must be used!

• The wall ladder legs must be dimensioned so that the distance

between the center line of the ladder’s rungs and the eaves or

other protrusion is at least 200 mm. The legs are to be shortened

to a suitable length, if necessary. The wall ladder legs must be

fastened to the wall material with the aid of a suitable fastening

method. While fastening the ladder, measures must be taken to

prevent water trickling down the wall from entering the wall

structures by, e.g., sealing the seams between the cladding and

brackets.

• The wall ladder legs must be fastened to the ladder with wall

ladder clips so that the topmost pair of legs is located as close to

the eaves as possible and the bottom pair of legs is located

between the first and second rung. Efforts must be made to

always fasten the wall ladder legs to the load-bearing structures of

the wall. In the case of brick-cladded houses, it is advisable to

install the wall ladder legs in the frame structure before bricklaying.

The maximum distance between the pairs of wall ladder legs is

3,000 mm. The wall ladder clips are fastened with two M8x16

screws and one M8x40 screw.

• The wall ladder legs are fastened to the eaves structure with the

aid of eaves supports. Eaves supports are to be used when the

length of the wall ladder legs exceeds 400 mm. The purpose of

the eaves supports is to support the ladder during vertical loading.

The eaves support is fastened to the wall ladder leg with an

M8x30 screw and to the eaves with a 7x50 self-tapping flange

screw.

2 x

7 x 50 SCREW

Timber frame or

paneled wall:

2 x 7x50 self-tapping

flange screw

Methods for fastening wall ladder legs to different materials:

Concrete/stone/block wall:

nylon or metal plug

suitable for the material in

question + 4 x 7x50

self-tapping flange screw

Sandwich panel:

separate mounting plate