Safety instruction manual

Cautions

Warnings

1. Rust and foreign substances in a piping may cause damage, malfunction or performance drop of the product. Flushing before use and

periodic ushing of a piping are recommended. Flushing on a tting type lter shall be done with a stem or short cut tube inserted into a

tting. Sealing parts in the tting may y out of it.

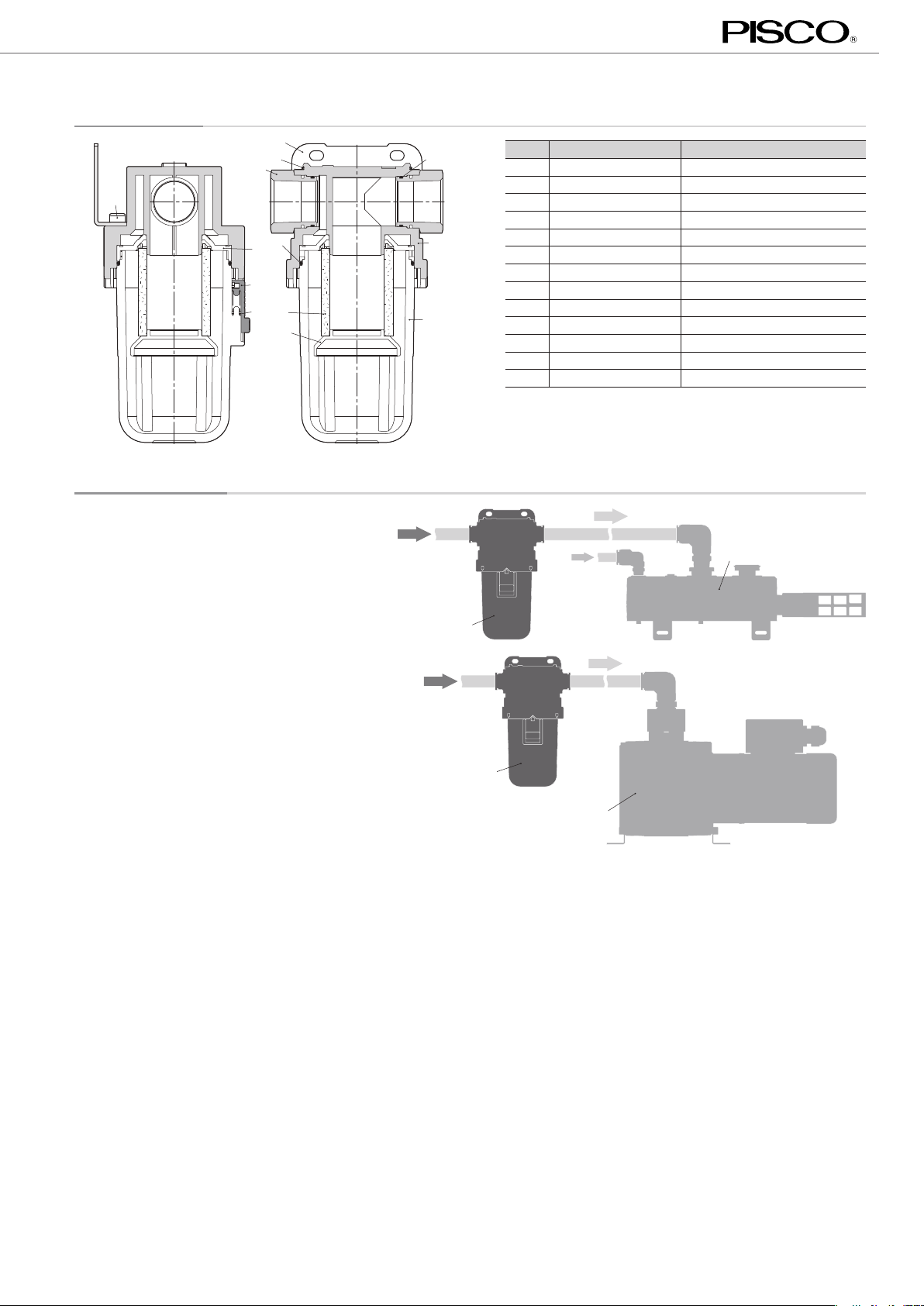

2. Check the arrow▷(IN→OUT) marking on a lter before installing. Installation with a wrong direction does not fulll the lter performance.

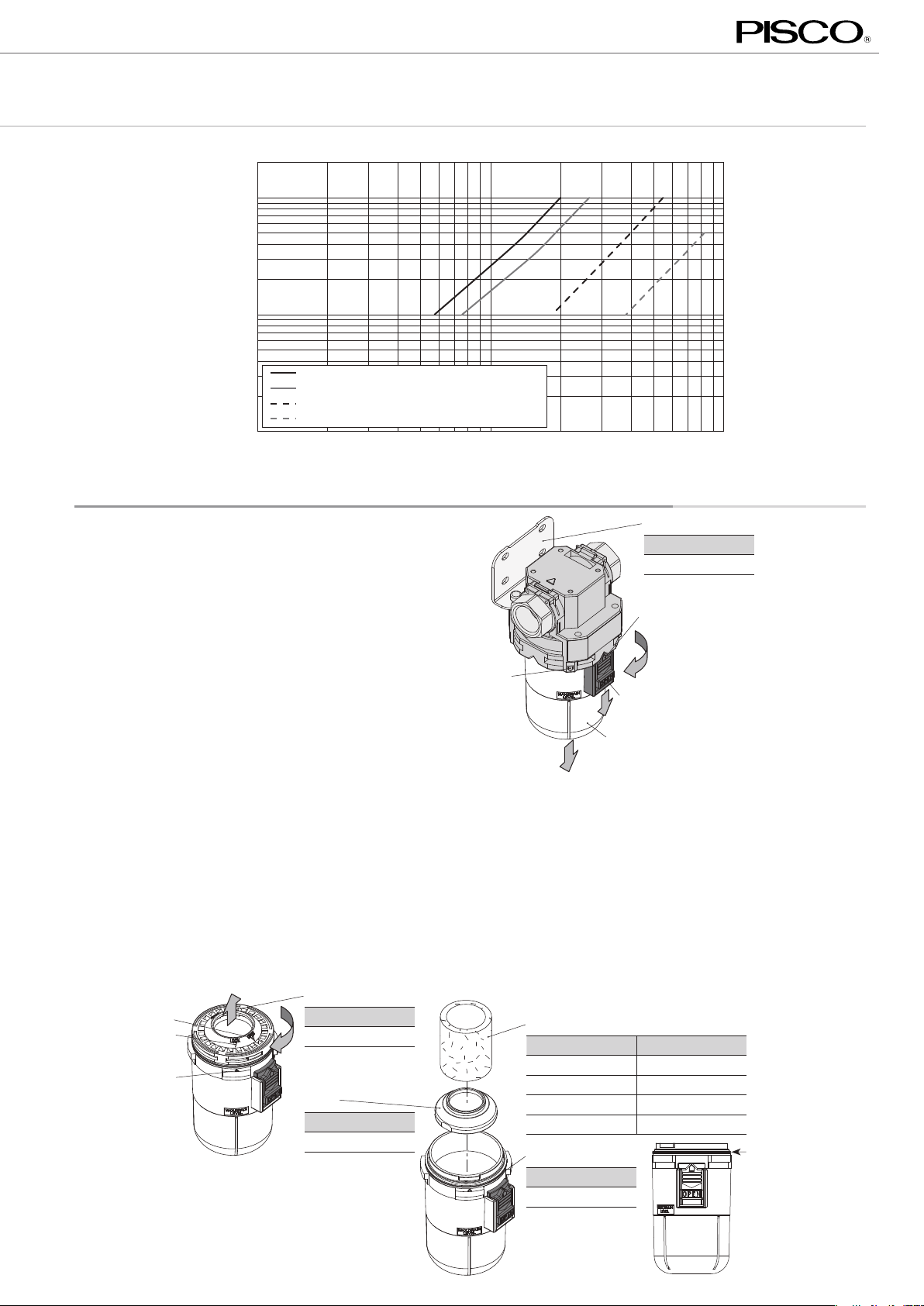

3. Lock the bowl properly and make sure that there is no vacuum leakage after removing dust or replacing a lter element.

4. Keep dust particles or drain water in a bowl lower than “MAX. DRAIN LEVEL” marking on it. Airow may ing up the dust in the bowl,

causing a signicant reduction of the lter element lifetime.

5. Hold a hex. part on each port by a spanner wrench, when connecting a tting with male thread, to prevent co-rotation of each port. Refer

to the tightening torque in the Table-2.

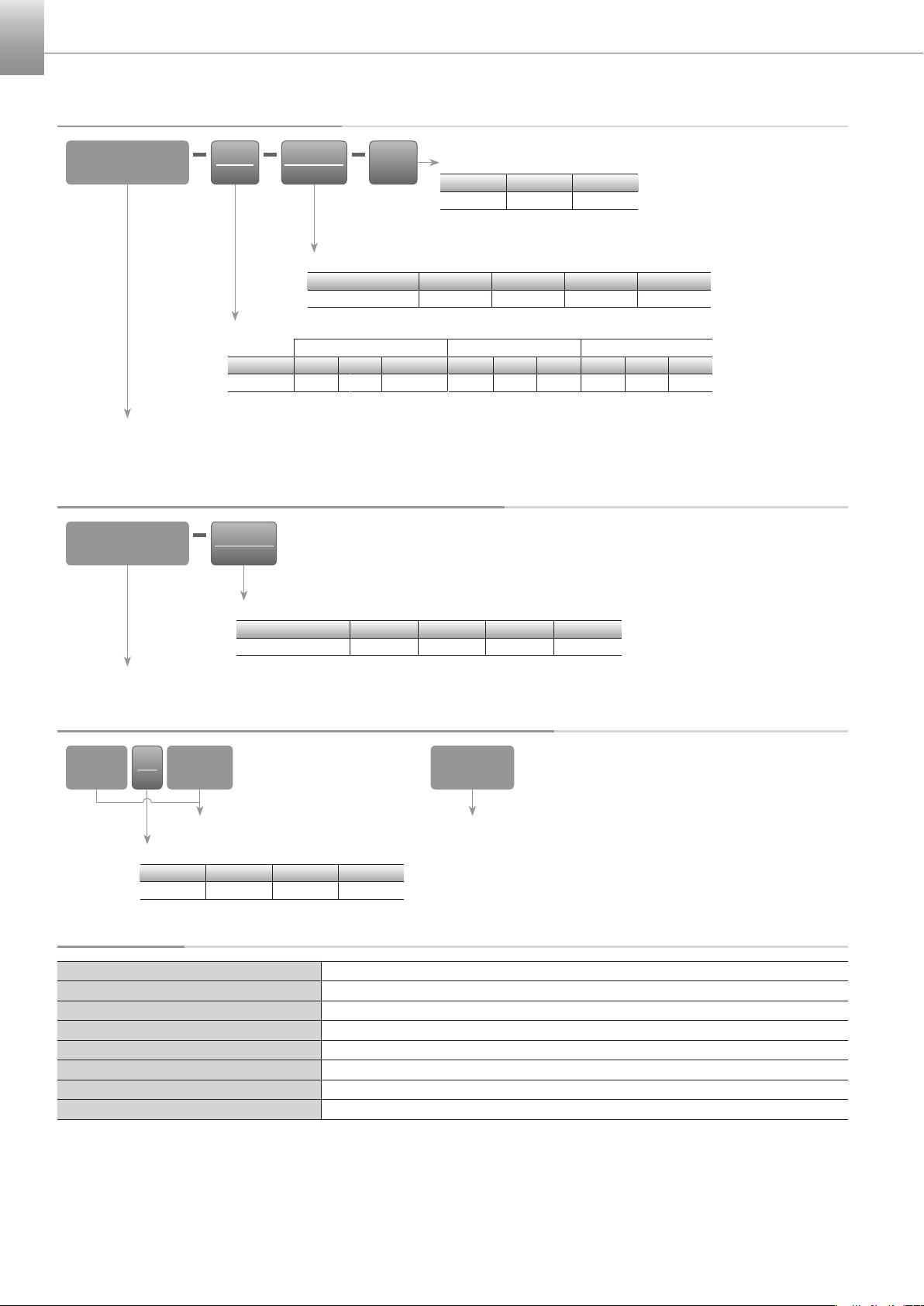

Table-2. Tightening torque (Reference)

Thread type Thread size Tightening torque

Taper pipe

thread

R3/8 12.5~14.5N·m

R1/2 20~22N·m

R3/4 30~35N·m

Parallel pipe

thread

G3/8 Follow the tightening torque of

male thread.

G1/2

G3/4

6. Install or x the product with its bowl facing down and vertically.

7. Re-torque the bracket xing screws periodically.

1. Avoid tensile strength or moment load on the product body and the tting cartridge. It may damage the product.

2. Carry out the maintenance of lter element periodically. There is a possibility of dropping the performance or causing troubles by clogging

of the lter element. Before replacing the lter element, make sure to read “How to remove the dust in bowl and replace a lter element”

carefully, release pressure and remain atmospheric pressure condition in the lter.

3. This product is not designed to be explosion-proof. Do not apply any positive pressure except momentary pressure for blow-off. It may

cause damage to the product and cause injury.

4. Bowl material is polycarbonate. Avoid chemicals or atmosphere with chemicals listed in the table-1 below.The bowl may get broken and

injure human body.

Table-1. Chemicals to be avoided

Chemical type Classication Chemicals (Major chemicals only) Applications

Inorganic

compound

Acid Hydrochloric acid, Sulfuric acid, Nitric acid, Hydrouoric

acid, Chromic acid, etc. Metal pickling solution, Acid cleaning liquid, Coating

treatment liquid, etc

Alkali Alkaline substances like Sodium hydroxide, Caustic potash,

Slaked lime, Aqueous ammonia, Sodium carbonate, etc. Alkaline cleaning liquid for metal

Organic

compound

Inorganic salt

Sodium sulphide, Potassium nitrate, Potassium bichromate, Sodium nitrate, etc.

Aromatic hydrocarbon Benzene, Toluene, Xylene, Ethylbenzene, Styrene, etc. Contained in paint thinner (Benzene, Toluene, Xylene)

Aliphatic hydrocarbon

chloride

Methyl chloride, Ethylene chloride, Methylene chloride, Acetylene chloride,

Chloroform, Triclene, Perchloroethylene, Carbon tetrachloride, etc

Organic solvent-based cleaning liquid for metal

(Triclene, Perchloroethylene, Carbon tetrachloride, etc)

Aromatic hydrocarbon

chloride Chlorobenzene, Dichlorobenzene, Benzenehexachloride

(B.H.C), etc. Agrochemical

Petroleum components

Solvent, Naphtha, Gasoline

Alcohol Methyl alcohol, Ethyl alcohol, Cyclohexanol, Benzyl alcohol Used as anti-freezing agent.

Phenol Carbolic acid, Cresol, Naphthol, etc. Disinfectants

Ether Methyl ether, Methyl ethyl ether, Ethyl ether, etc. Brake oil additive

Ketone Acetone, Methyl ethyl ketone, Cyclohexanone,

Acetophenone, etc.

Carboxylic acid Formic acid, Acetic acid, Butyric acid, Acrylic acid, Oxalic

acid, Phthalic acid, etc. yeing agent, Oxalic acid for treatment agent of

Aluminum, Phthalic acid for paint plasticizer.

Organophosphate Dimethyl phthalate (DMP), Diethyl phthalate (DEP), Dibutyl

phthalate (DBP), Dioctyl phthalate (DOP)

Grease, Synthetic hydraulic oil, Rust preventive oil

additive, Used as synthetic resin plasticizer.

Oxoacid

Glycolic acid, Lactic acid, Malic acid, Citric acid, Tartaric acid

Nitro compound Nitromethane, Nitroethane, Nitroethylene, Nitrobenzene,

etc.

Amine Methylamine, Dimethylamine, Ethyl amine, Aniline,

Acetaniline, etc. Brake oil additive

Nitrile Acetonitrile, Acrylic nitrile, Benzonitrile, Aceto isonitrile, etc. Material of Nitrile rubber

*There is some possibilities that other chemicals not listed in the table above may not be used. Please make sure to carry out sufcient

evaluation before use.