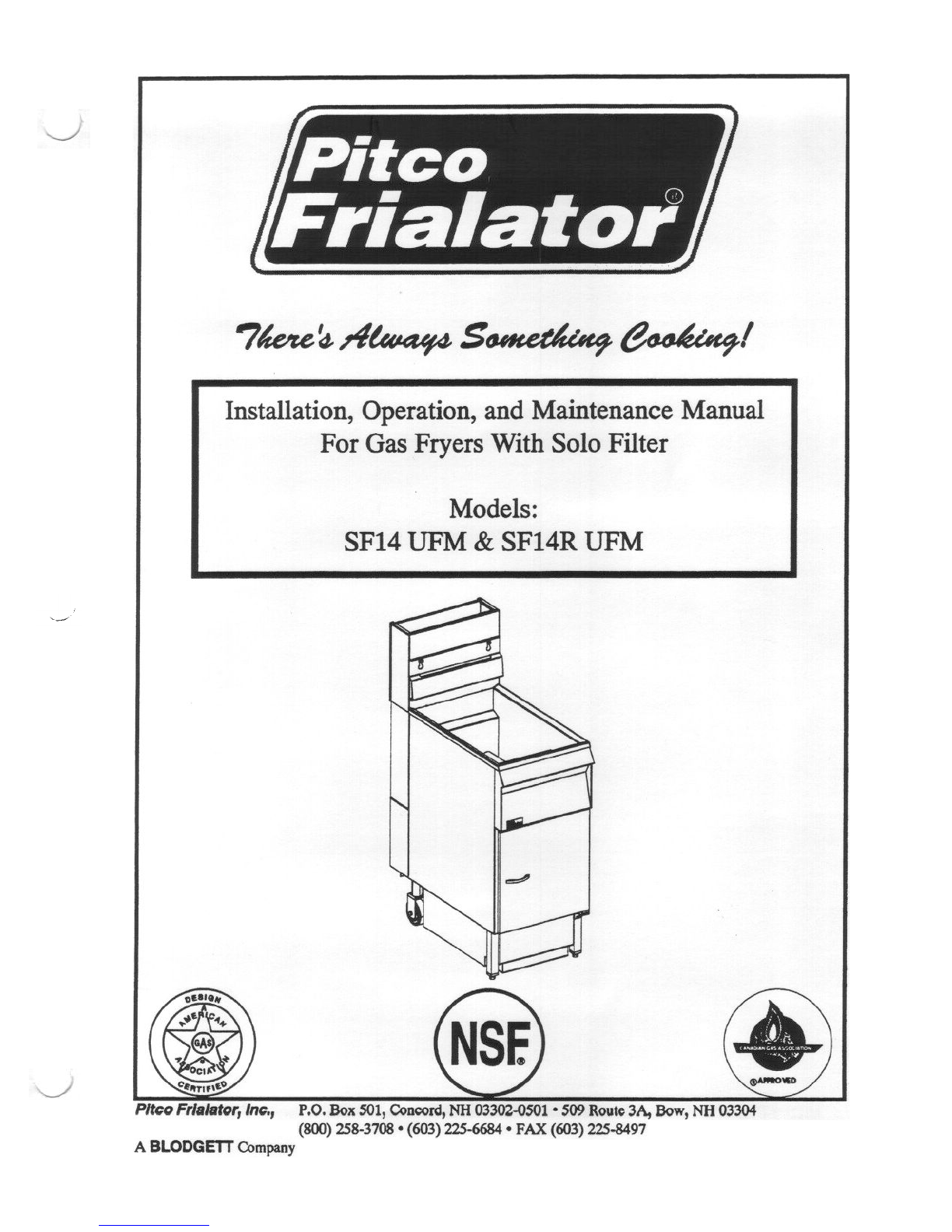

Pitco Frialator SF14 UFM Guide

Other Pitco Fryer manuals

Pitco

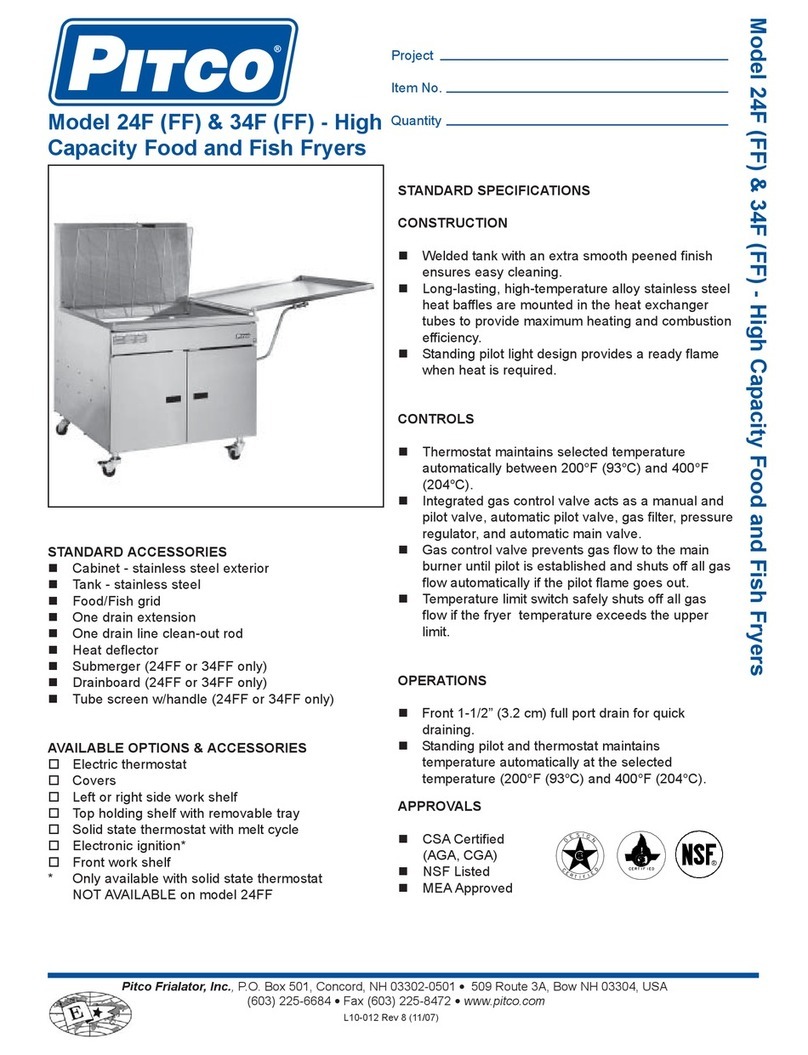

Pitco 24F User manual

Pitco

Pitco SE Series User manual

Pitco

Pitco 14T User manual

Pitco

Pitco PE14D User manual

Pitco

Pitco SG14C User manual

Pitco

Pitco First Choice L22-282 Guide

Pitco

Pitco SG User manual

Pitco

Pitco Frialator SG 14R User manual

Pitco

Pitco SGH50 User manual

Pitco

Pitco Frialator SG 18 User manual

Pitco

Pitco SSHLV Series User manual

Pitco

Pitco SGH50 Operating and installation instructions

Pitco

Pitco Frialator SG 18 User manual

Pitco

Pitco E7 Guide

Pitco

Pitco SEH50 Service manual

Pitco

Pitco 20F User manual

Pitco

Pitco SE14 User manual

Pitco

Pitco E12SS User manual

Pitco

Pitco L22-355 User manual

Pitco

Pitco Frialator SG 14 User manual