UK

Safety Tips

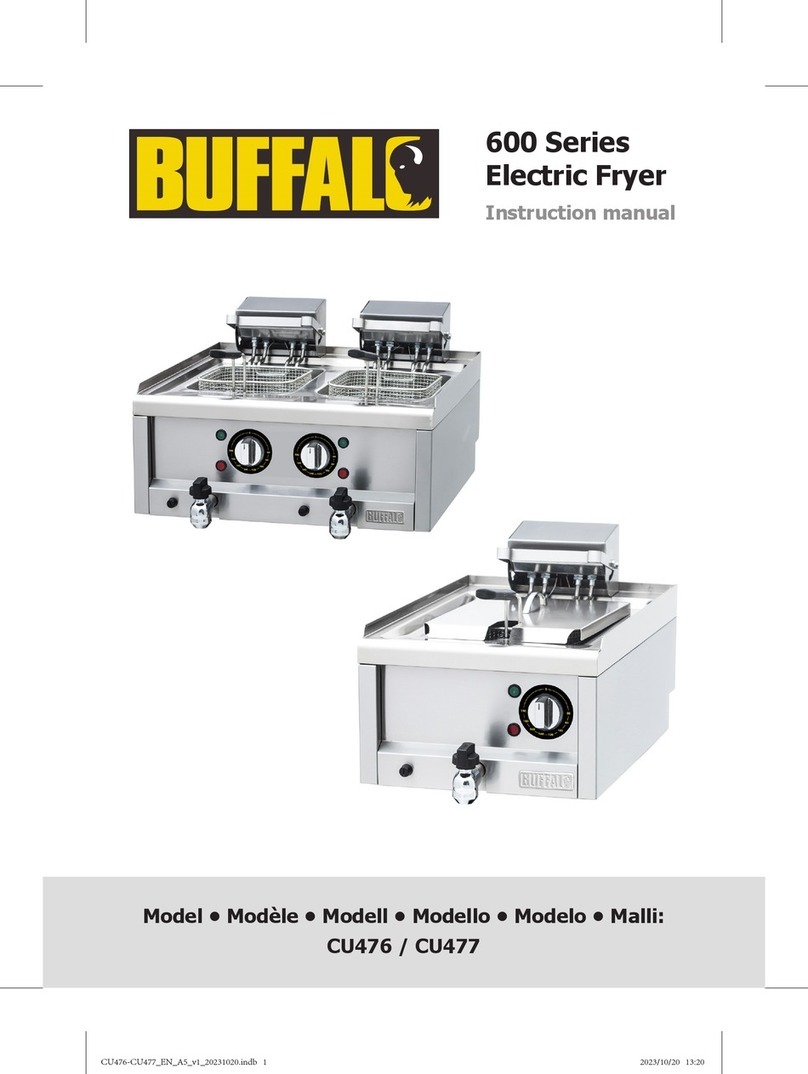

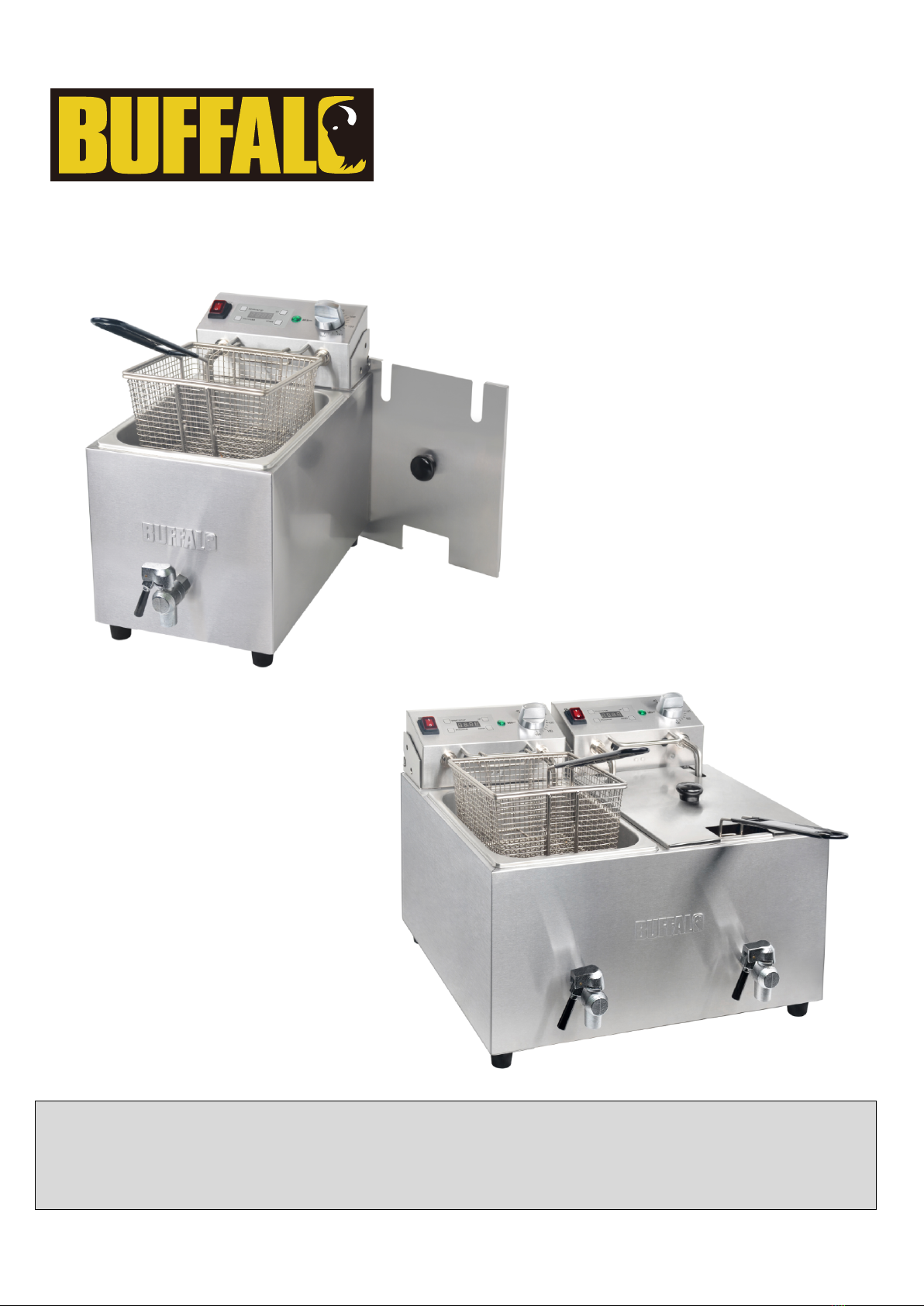

Position on a flat, stable surface.

A service agent/qualified technician should carry out installation and any repairs if required.

Do not remove any components on this product.

Consult Local and National Standards to comply with the following:

oHealth and Safety at Work Legislation

oBS EN Codes of Practice

oFire Precautions

oIEE Wiring Regulations

oBuilding Regulations

DO NOT immerse the electrical control box assembly in water, or use jet/pressure washers to

clean the appliance

Do not use the appliance for anything other than its intended use.

Always switch off and disconnect the power supply to the appliance when not in use.

Not suitable for outdoor use.

Keep all packaging away from children. Dispose of the packaging in accordance to the

regulations of local authorities.

If the power cord is damaged, it must be replaced by a BUFFALO agent or a recommended

qualified technician in order to avoid a hazard.

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning the use of the appliance by a person responsible

for their safety.

Ensure oil levels are maintained above the minimum indicated level. Failing to maintain the

required level may result in element failure.

The manufacturers of Buffalo products take every care to ensure that all products are safe.

Steel cutting procedures used to manufacture these items results in sharp edges. These

sharp edges are removed to the best of our ability; however we still insist the operator takes

care when in contact with this piece of equipment.

Switch off power to the Fryer, and remove the plug from the power socket whilst cleaning,

draining oil, or filling with oil.

Change the oil regularly. Used oil breaks down after use, it can catch fire as its flash point is

reduced, and it is more prone to surge boiling.

The oil pan should not be covered during frying –Lid should not be fitted when unit in use.