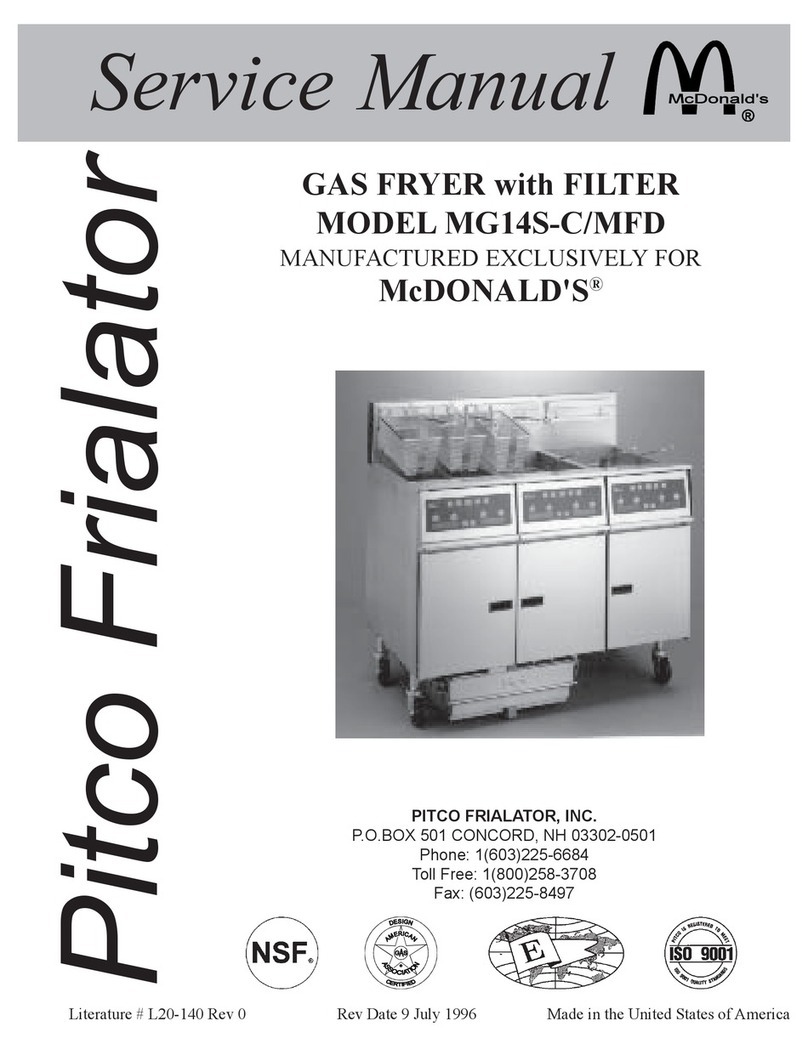

STANDARDOPTIONSANDACCESSORIES

nDigital solid state control

nFour oblong nickel plated baskets

nCleaning brush nFilter bags

nSkimmer nFlush hose

nFilter removal tool nDrain screen

nClean out rod nFilter scoop

nBasket hanger

nHeavy duty polyurethane casters

nStainless steel tank

nStainless steel cabinet front and sides.

AVAILABLE OPTIONS & ACCESSORIES

FSolid shortening system FSquare baskets (2)

FI12 computer F1/3 style baskets (6)

FQuick 1" x 36" disconnect

FStainless steel lift off cover

FFront work shelf

FSide work shelf

FBatter coated food baffle

F2 year extended warranty

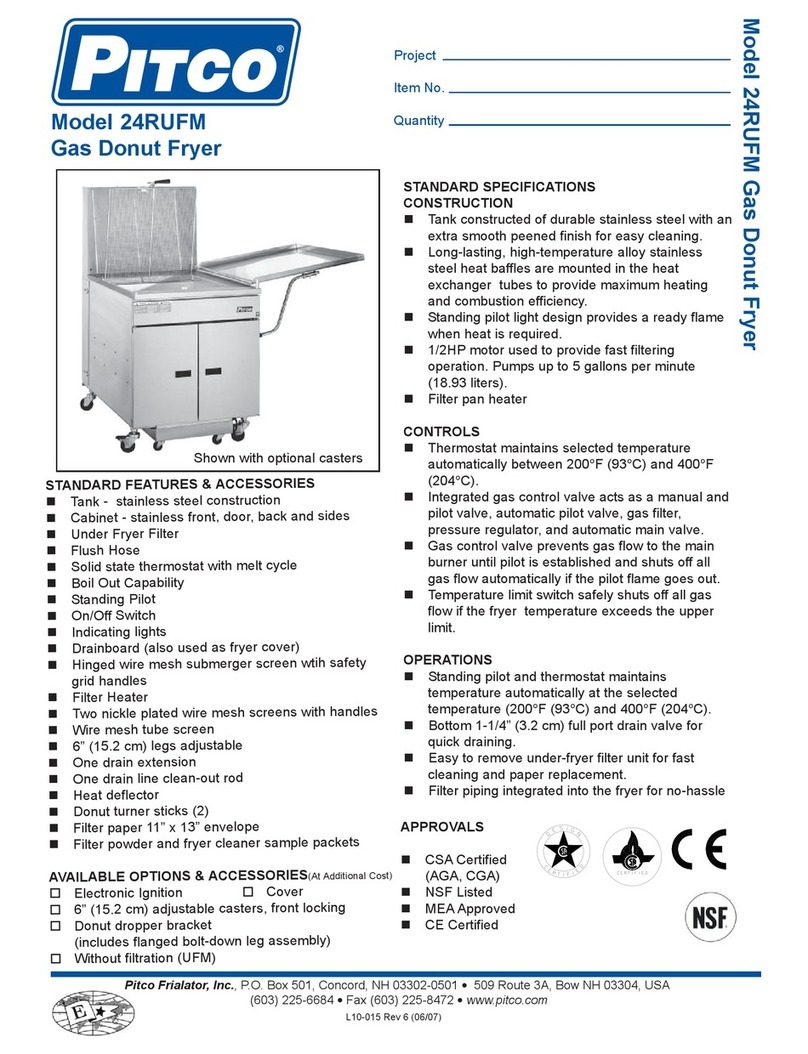

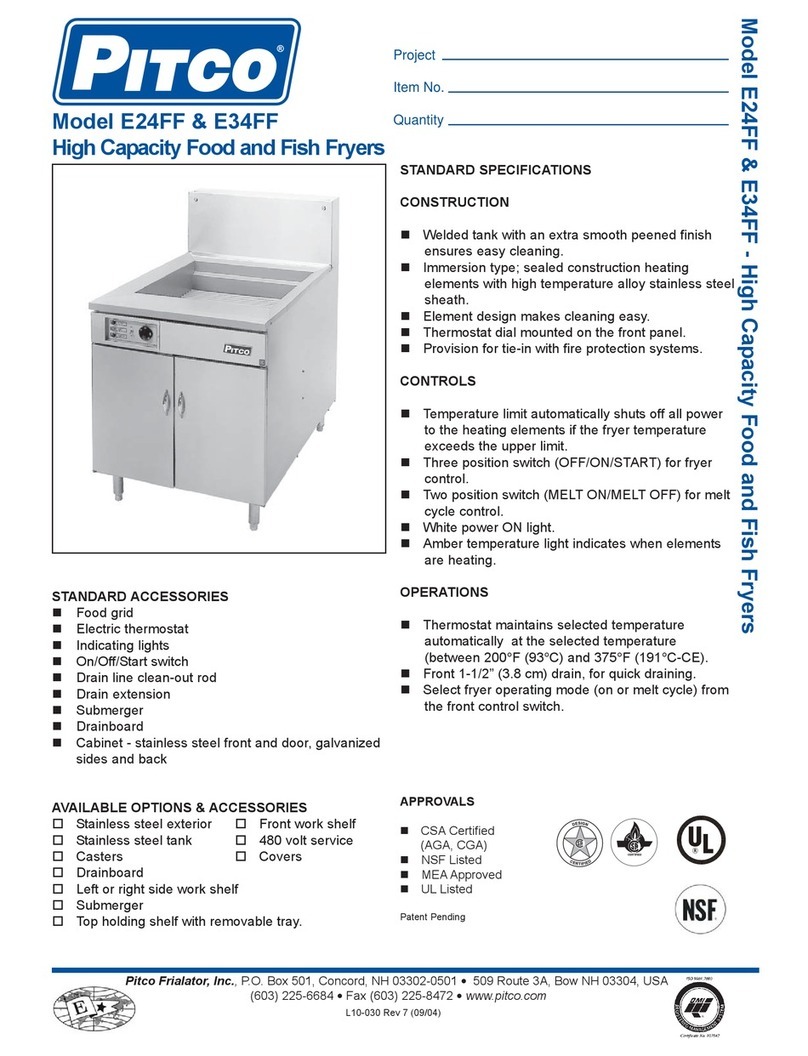

STANDARD SPECIFICATIONS

CONSTRUCTION

nWelded tank with a super smooth machine peened

finish ensures easy cleaning.

nState of the art digital solid state cooking controller

with integral melt cycle is accurate to ±1 degree.

nHeavy duty institutional type construction for years of

rugged performance.

nAhigh rate power burner to meetthe highest production

demands.

nSpecial diameter heat tube and heat recuperation

system transfers heat efficiently with low heated

surface temperatures for improved oil life.

nRigid tubular steel frame with stainless steel front and

sides. Sides remove easily for cleaning.

nSplash back and front deck are 14 gauge stainless

steel. Doors are self closing.

nContinuous filter system is integral to the tank. High

flow filters have large collection capacity and are fast

to change.

CONTROLS

nDigital controller maintains fryer temperature between

250°F and 380°F.

nDigital controller provides a visual display and audible

indication of temperature, high oil temperature, probe

failure, cook times, product ready and other events.

Each digital controller product key is fully field

programmable.

nFront panel mounted gauges provide the operator with

status of the filters and pump operation.

nTemperature limit automatically shuts off all gas flow

if the fryer temperature exceeds 450°F (232°C) ±15°F

(±10°C).

OPERATIONS

nDirect spark ignition for easy start-ups.

nFront 1-1/4" NPT full port drain valve with 11-1/2" floor

clearance for easy draining.

nSafety interlock on drain valve stops heat and pump

functions if drain is opened.

nContinuous filter removes excess breading from the

oil.

nHighpoweredheatingsystem provides low temperature

drop under full load cooking.

nFlush hose for wash down or shortening disposal.

APPROVALS

nAGA Certified

nCGA Certified

nNSF Listed *PatentPending

Project

Item No.

Quantity

ModelTURBOFRY 2000

Gas Continuous Filtration

Convection Fryer

Pitco Frialator, Inc., P.O. Box 501, Concord, NH 03302-0501 • 509 Route 3A, Bow, NH 03304, USA

(800) 258-3708 • (603) 225-6684 • FAX (603) 225-8472